- Overview

- Product Description

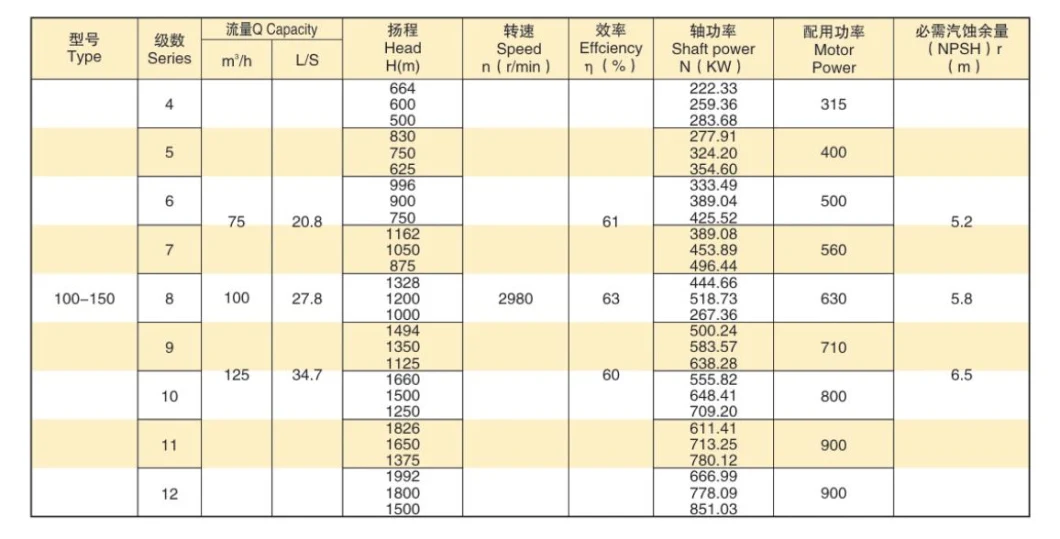

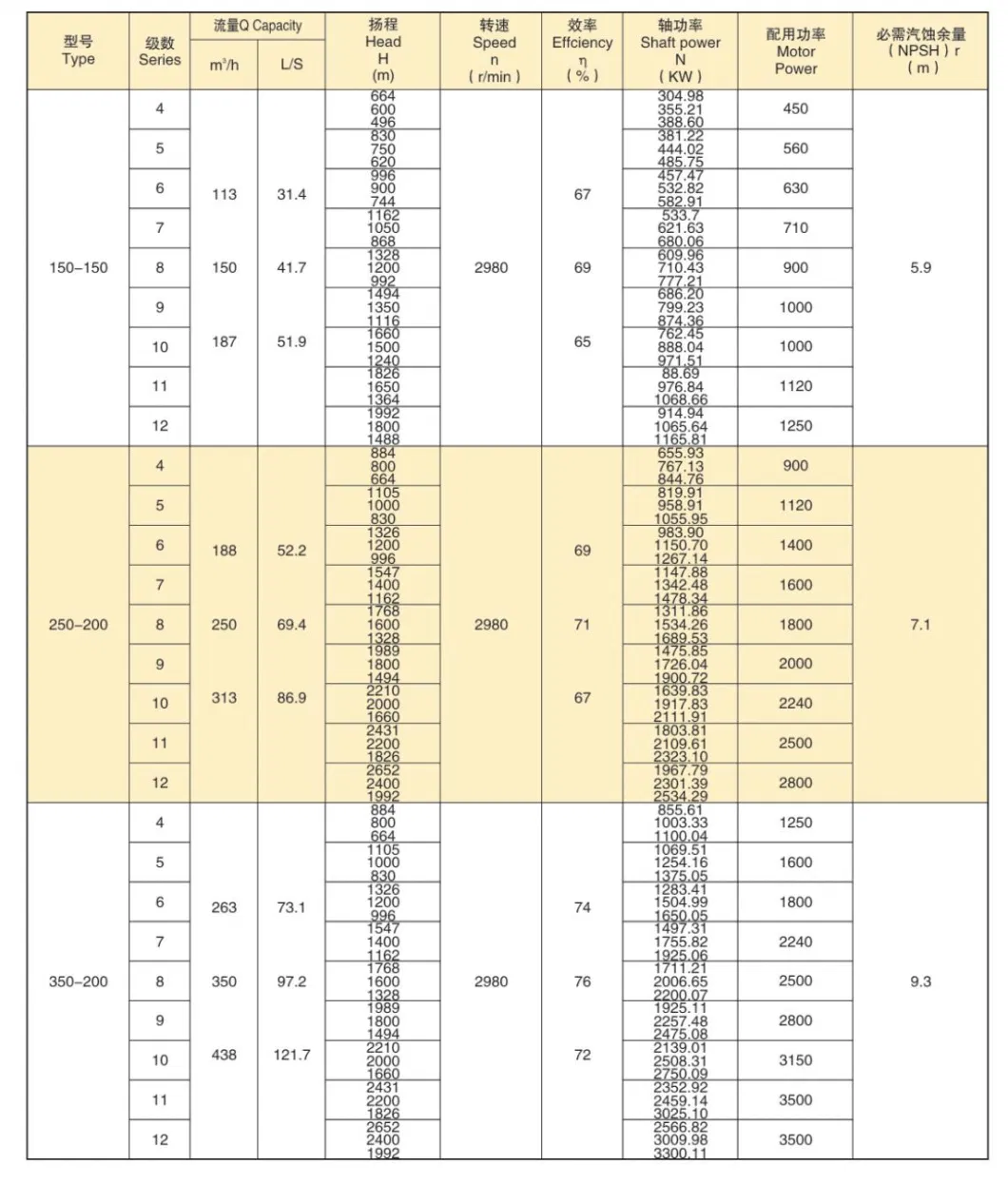

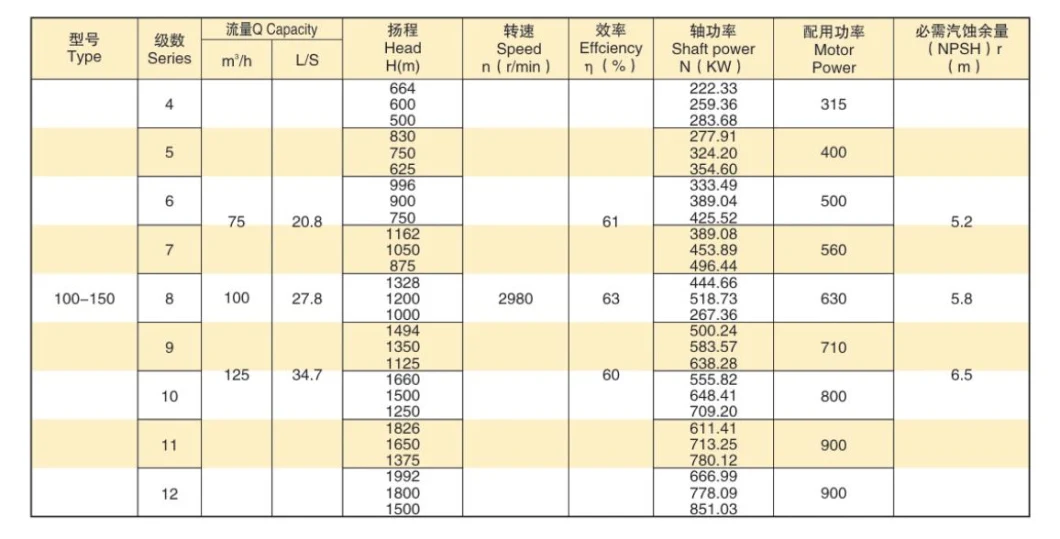

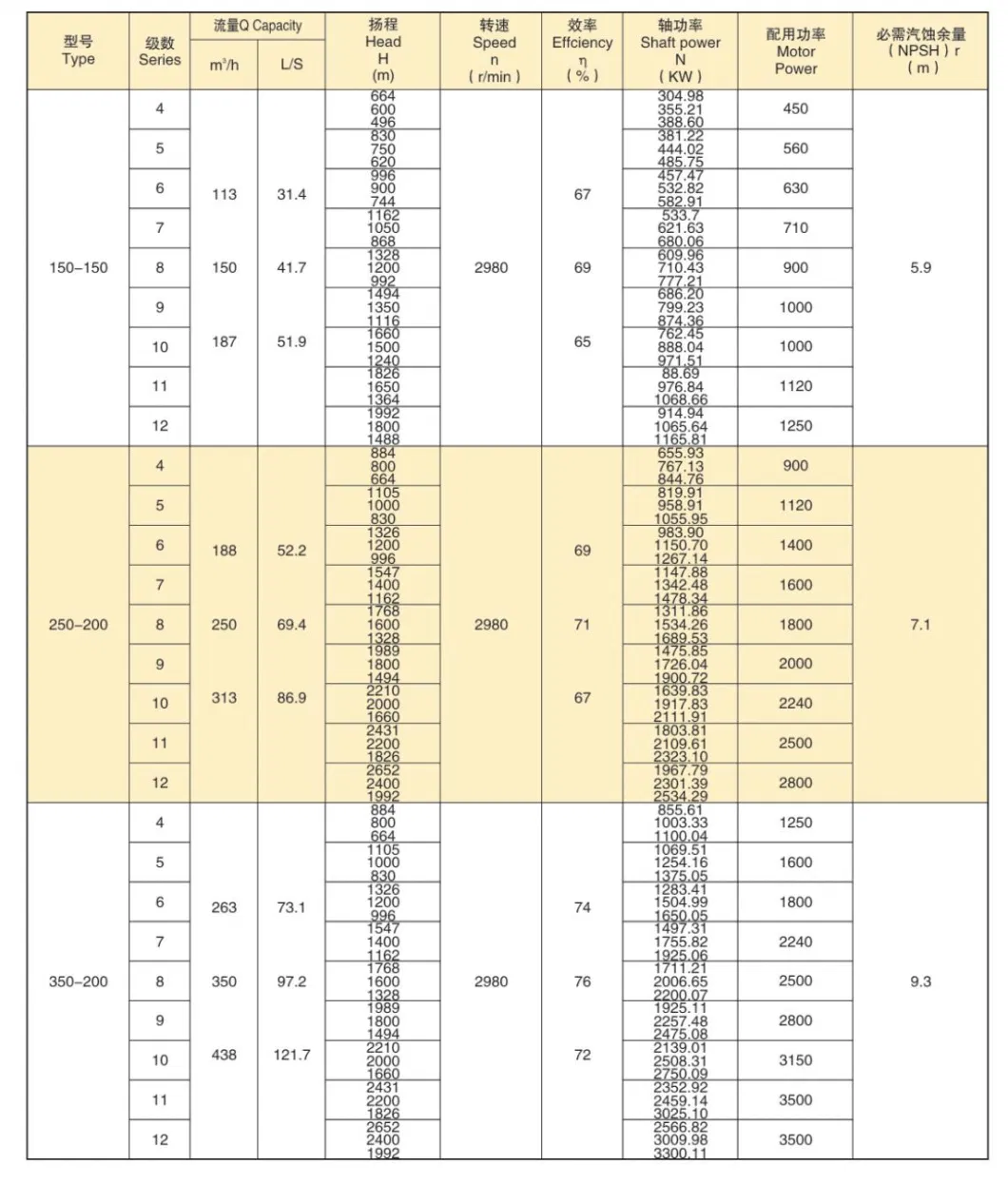

- Chart

- Product Parameters

- Company Profile

- FAQ

Basic Info.

Model NO.

BB5(FHB)

Position of Pump Shaft

Horizontal Pump

Pump Casing Combined

Horizontal Split Pumps

Mounting Height

Suction Centrifugal

Impeller

Closed

Usage

Pump, Pumps, Condensate Pump, Slurry Pump, Circulating Pump

Capacity

50~800m3/H

Head

~2600m

Temperature

-80~450degree

Standard

API610

Rotation Speed

2980

Package

Plywood Box

Transport Package

Plywood Box

Trademark

Feiyue

Origin

Jiangsu, China

Production Capacity

5000

Product Description

API 610 Series Bb5 (FHB) Multistage High-Temperature High-Pressure Centrifugal Pump for Oil and Gas Chemical Industry

It can transport particle contained(particle diameter less than 1/4 of impeller passageway) medium and hot water, oily medium, corrosive or abradant contained medium by changing pump materials(or transflux parts materials), seal type and adding cooling system.

FDSR series vertical, horizontal multi-stage centrifugal pump working temperature is -60 400ºC Material is optional including HT200, QT600, JM3, 28# alloy, 304, 304L, 316L, 317L, 904L, CD4, Ha's C, Ha's B etc.

Our company passed 1S09001:2008 quality system cert cate. We have strict and standard control system in product design, manufacturing and service. Product quality is fully guaranteed.

Conform to design standard of APl610

Flow range: 50~800m3/h

Lift range: ~2600m

Application temperature: -80~+450ºC

Application field: This series of pump is mainly used in industries of oil refinery, petrochemical engineering, low temperature engineering, coal chemical industry, power plant, environmental protection engineering,

Wastewater treatment, cement plant etc.Suitable for transporting all kinds of neutral or corrosive normal-temperature or high-temperature medium such as clean, particle free chemical medium, oil, wastewater.

Flow range: 50~800m3/h

Lift range: ~2600m

Application temperature: -80~+450ºC

Application field: This series of pump is mainly used in industries of oil refinery, petrochemical engineering, low temperature engineering, coal chemical industry, power plant, environmental protection engineering,

Wastewater treatment, cement plant etc.Suitable for transporting all kinds of neutral or corrosive normal-temperature or high-temperature medium such as clean, particle free chemical medium, oil, wastewater.

Main manufacture materials and applicable medium.

It can transport particle contained(particle diameter less than 1/4 of impeller passageway) medium and hot water, oily medium, corrosive or abradant contained medium by changing pump materials(or transflux parts materials), seal type and adding cooling system.

FDSR series vertical, horizontal multi-stage centrifugal pump working temperature is -60 400ºC Material is optional including HT200, QT600, JM3, 28# alloy, 304, 304L, 316L, 317L, 904L, CD4, Ha's C, Ha's B etc.

Our company passed 1S09001:2008 quality system cert cate. We have strict and standard control system in product design, manufacturing and service. Product quality is fully guaranteed.

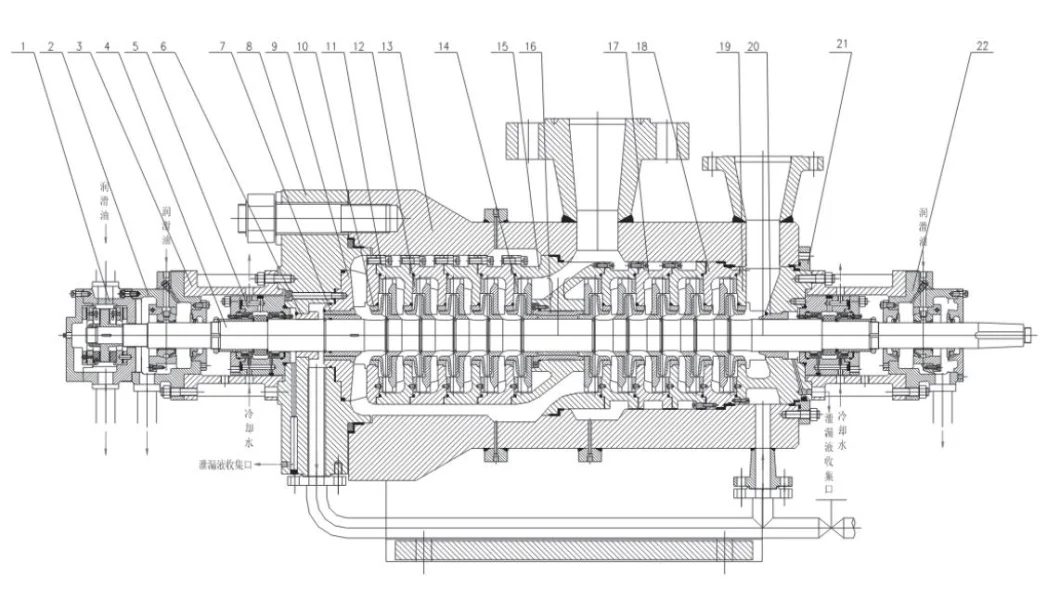

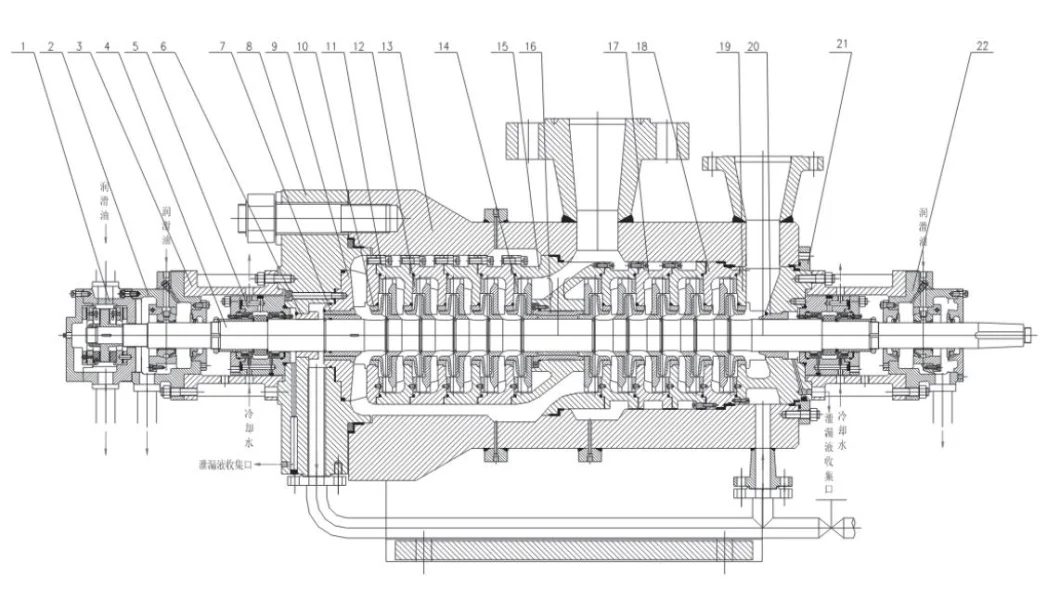

| 1 | Thrust bearing parts | 2 | Drive side sliding bearing parts | 3 | Beaing support | 4 | Rotor parts | 5 | Mechanical seal parts | 6 | Throttling set I |

| 7 | Throttling set II | 8 | Pump beast | 9 | Secondary guide plate | 10 | Mouth ring | 11 | High pressure in the middle | 12 | Guide vane |

| 13 | Shell | 14 | Level at the end of guide vane | 15 | Transition pipe | 16 | Throttling set Ill | 17 | Low pressure in the middle | 18 | Head in the middle |

| 19 | Head guide vane | 20 | Throttling set IV | 21 | Clamp | 22 | Drive side sliding bearing parts |

Performance parameters of the table