- Overview

- Company Profile

- Packaging & Shipping

- FAQ

Basic Info.

Model NO.

SDP

Max.Capacity

<50 L/min

Driving Type

Motor

Material

Cast Iron/SS304/SS316/Bronze

Structure

Multistage Pump

Assembly

Booster Pump

Power

Electric

Start Up

Electric Pump

Type

Blade Pump

Application

Clarified Water Pump

Industry

Air Conditioning Pump

Media

Clean Water

Performance

Automatic Pump

Theory

Centrifugal Pump

Inlet/Outlet Flange

G1.5" ~ G2" / G1.25"

Max. Operating Pressure

Pn1.3MPa

Shaft Sealing

Mechanical Seal

Trade Terms

EXW Price

Quality Guarantee

One Year After Commissioning

Quality Guarantee.

18 Months After Delivery

Transport Package

Standard Export Packaging

Specification

According to the drawings

Trademark

HydroBlue

Origin

China

HS Code

8413709990

Production Capacity

100000 PCS/Year

Packaging & Delivery

Package Size

30000.00cm * 12000.00cm * 20000.00cm

Package Gross Weight

3500.000kg

Product Description

General Description

The close-coupled twin-impeller centrifugal electric pump is designed for the pumping of clean water or any clear liquids which do not contain solids and are not corrosive, abrasive or explosive when in contact with the pump motor unit and its working parts

Design Features

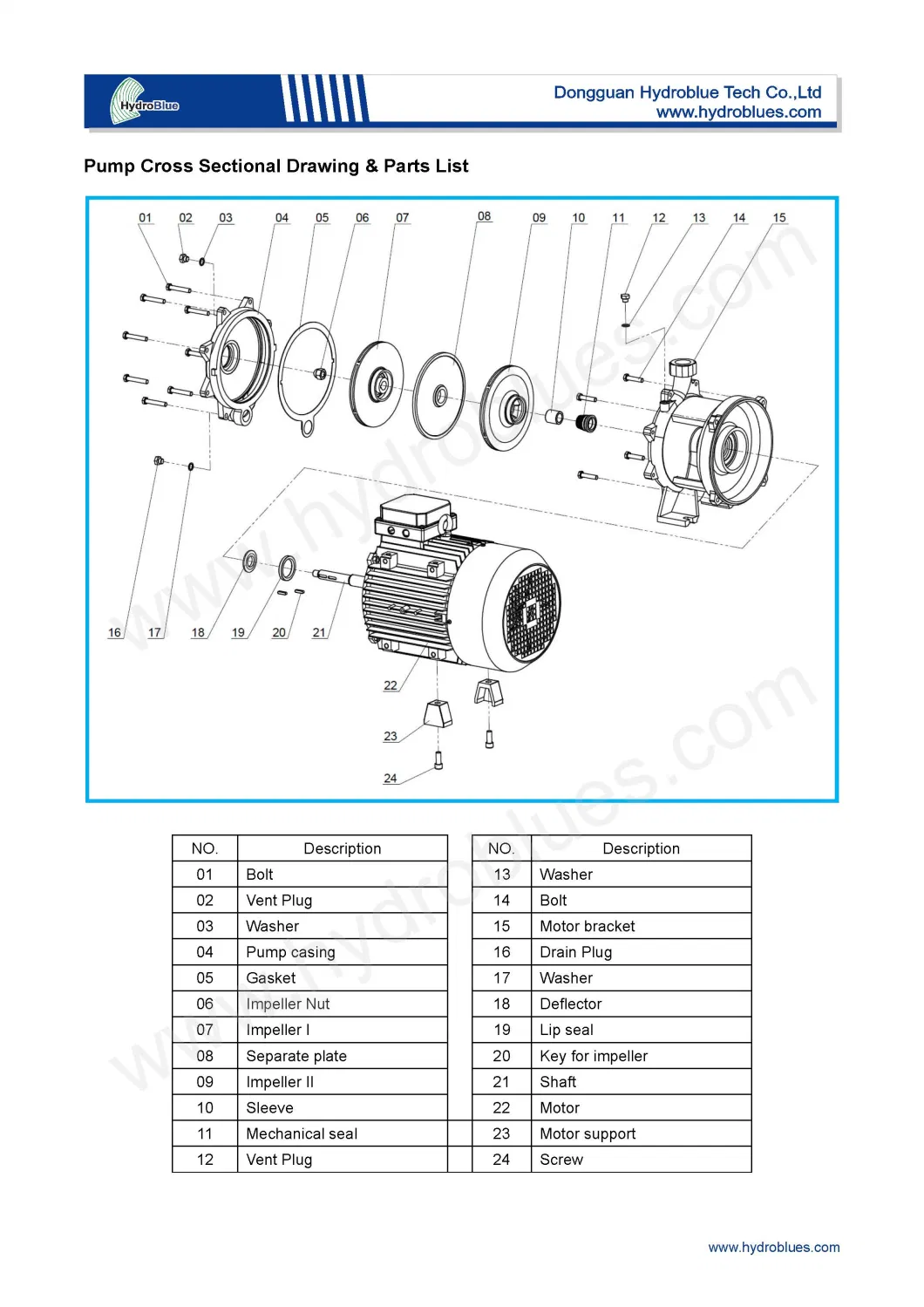

Monobloc / Close-coupled centrifugal electric pump, foot-mounted, Two-stage overhung pumps.

> Connection type: Female thread

> Casing structure: End suction, center radial discharge.

> Shaft seal: Single mechanical seal (Graphite / Ceramic / NBR / SS304), On request: Graphite / Silicon carbide / Viton / SS316.

> Driven shaft: Pump and motor flanged together to form a close-coupled unit, with common shaft.

> Axial force balance: Adopting impeller back-to-back configuration, effectively balancing axial force, reducing vibration and noise, and ensuring smoother operation of the electric pump.

Others

> Low maintenance costs.

> High operating reliability.

> Service-friendly design.

> Optimal tightness.

On Request

> Other operating voltages and frequencies

> Special mechanical seal; special liquids

> Special temperature

How to Read the Pump Model

The Direction of Rotation

The rotation of the pump rotor is clockwise looking from the motor to the pump.

Application

Water supply / Fire-fighting systems / Sprinkling / Irrigation / Drainage / Fire-fighting water / Domestic / Civil and industrial sectors

Close-coupled Two-stages, End-suction,

Centrifugal Electric Pumps

SDP Series Two-stage High Pressure Pump

APPLICATION:

> Water supply

> Fire-fighting systems

> Sprinkling

> Irrigation

> Drainage

> Fire-fighting water

> Domestic

> Civil and industrial sectors

> Water supply and transfer in municipal and industrial applications

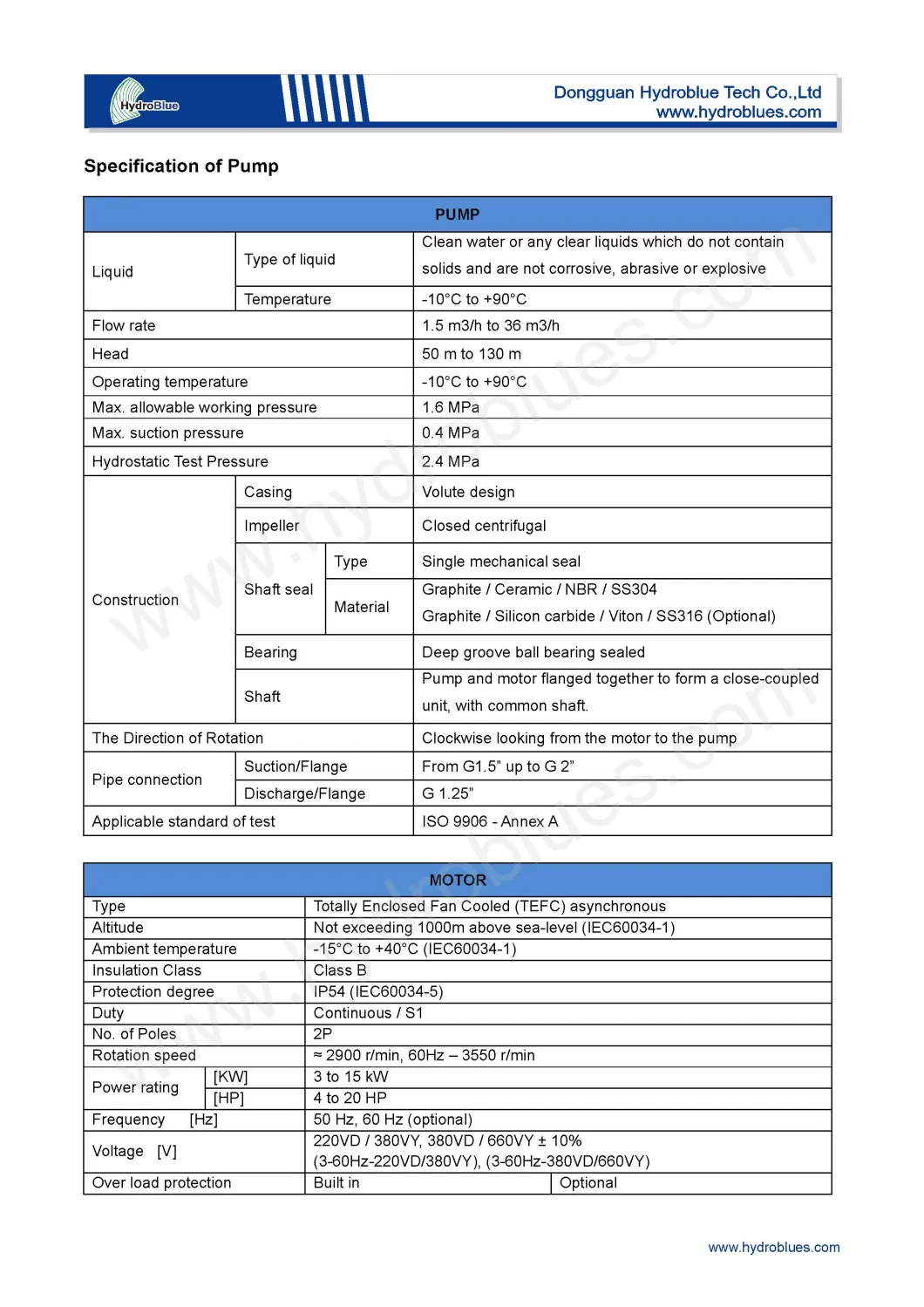

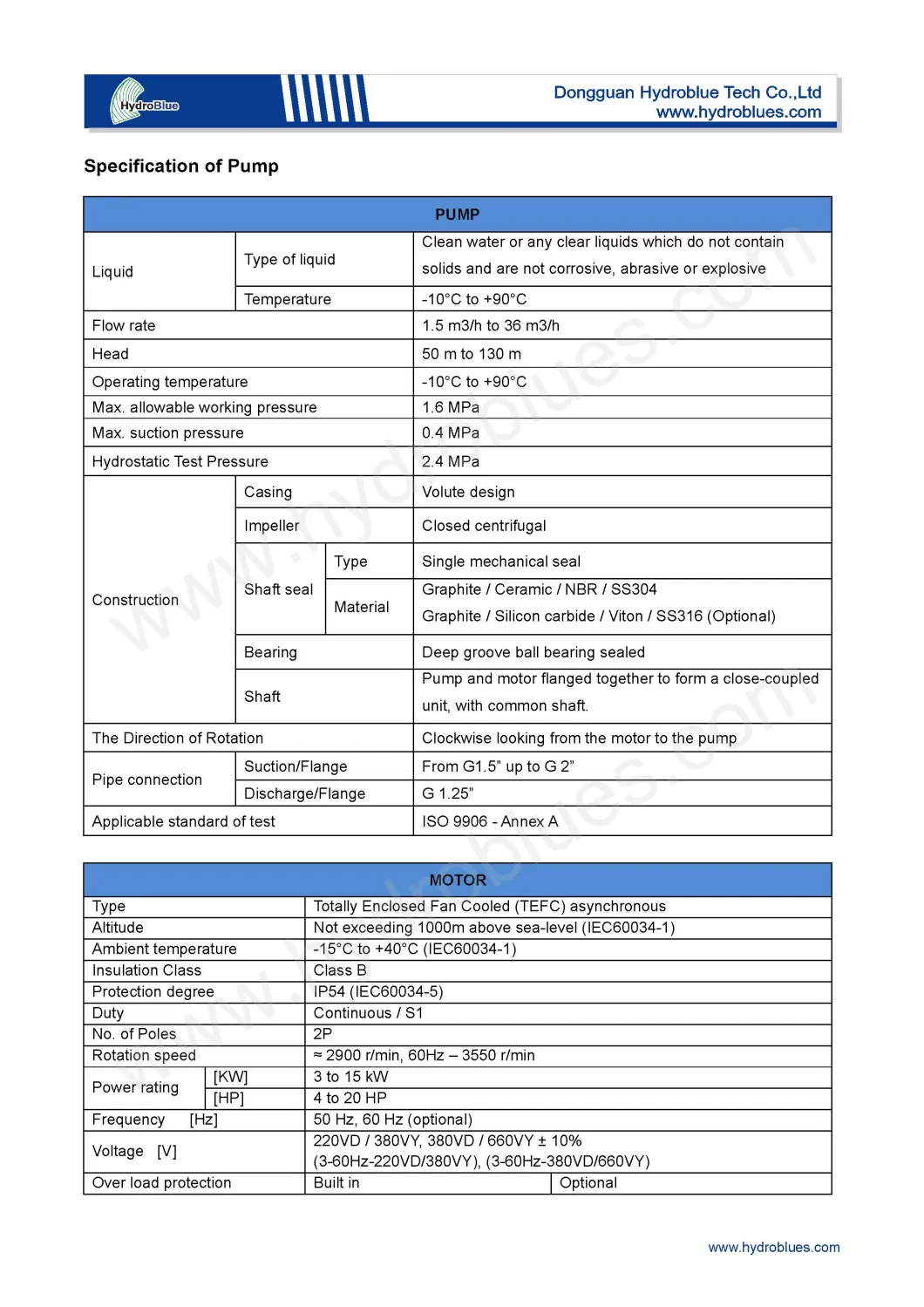

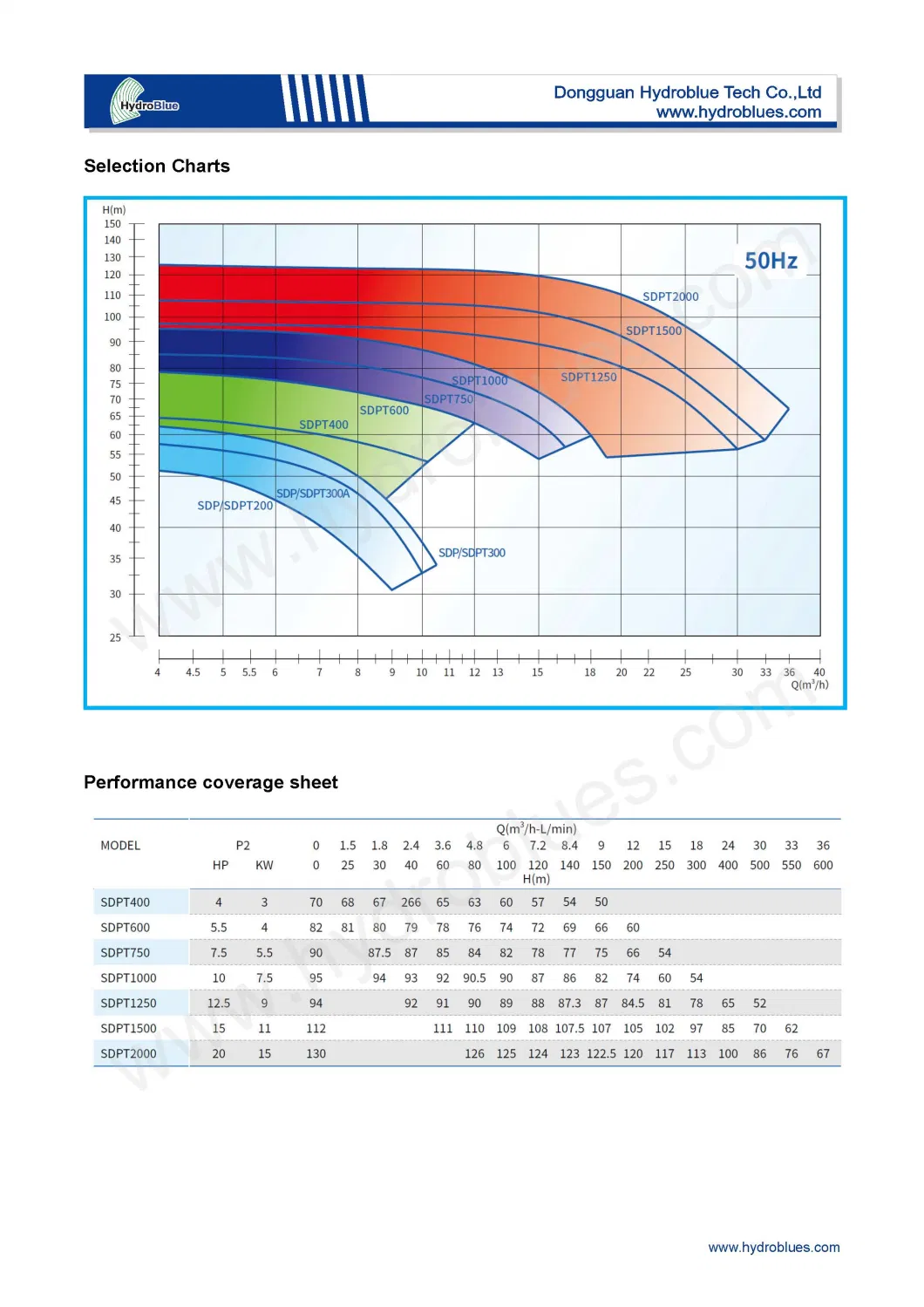

SPECIFICATIONS:

> Pump Suct. Size: 1.5 inch to 2 inch

> Pump Disc. Size: 1.5 inch

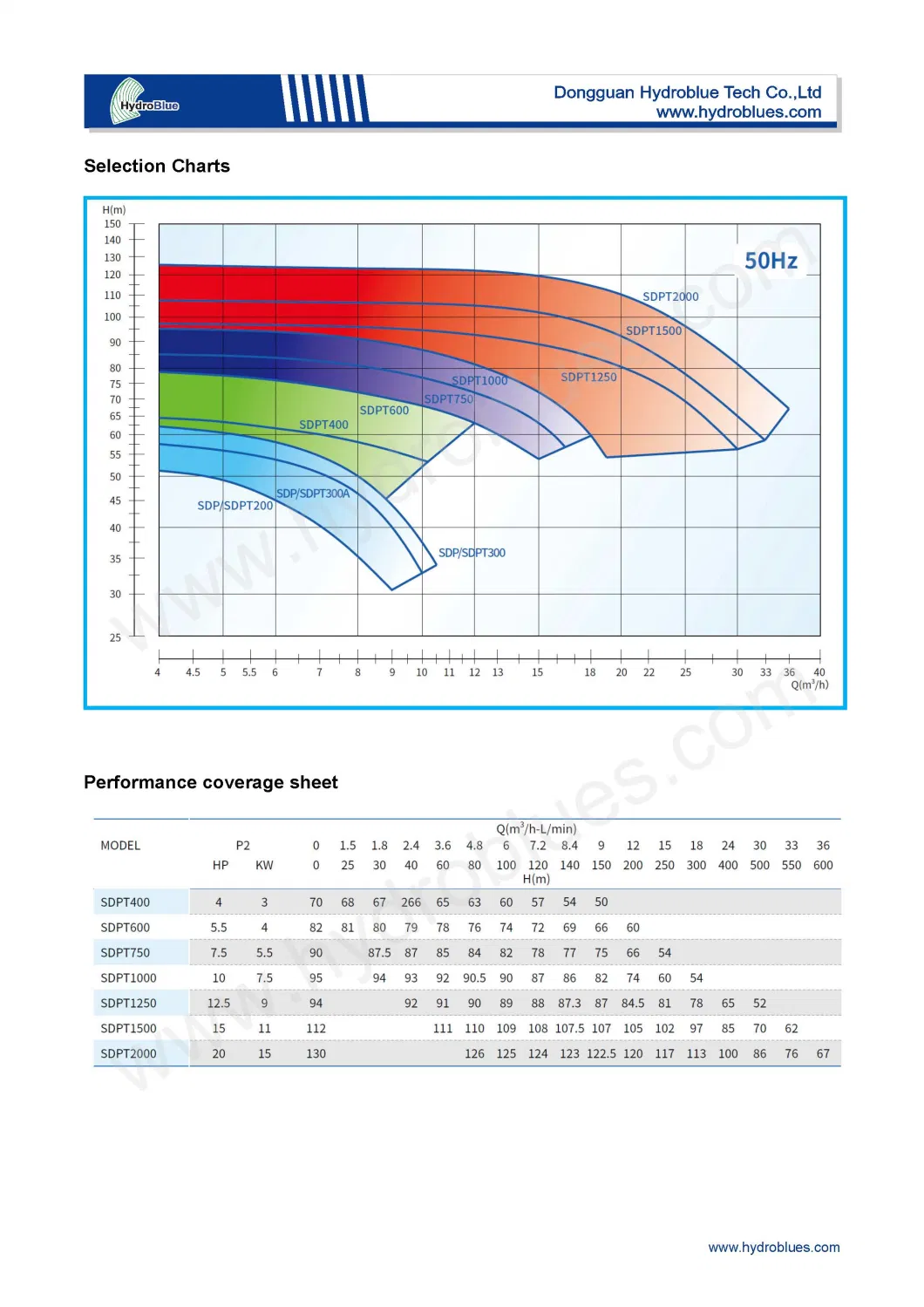

> Capacity Q: 1.5 m3/h to 36 m3/h

> Head H: 50 m to 130 m

> Speed: 50Hz or 60Hz, VFD

> Motor power: 3 kW to 15 kW

Product Standard: ISO9908

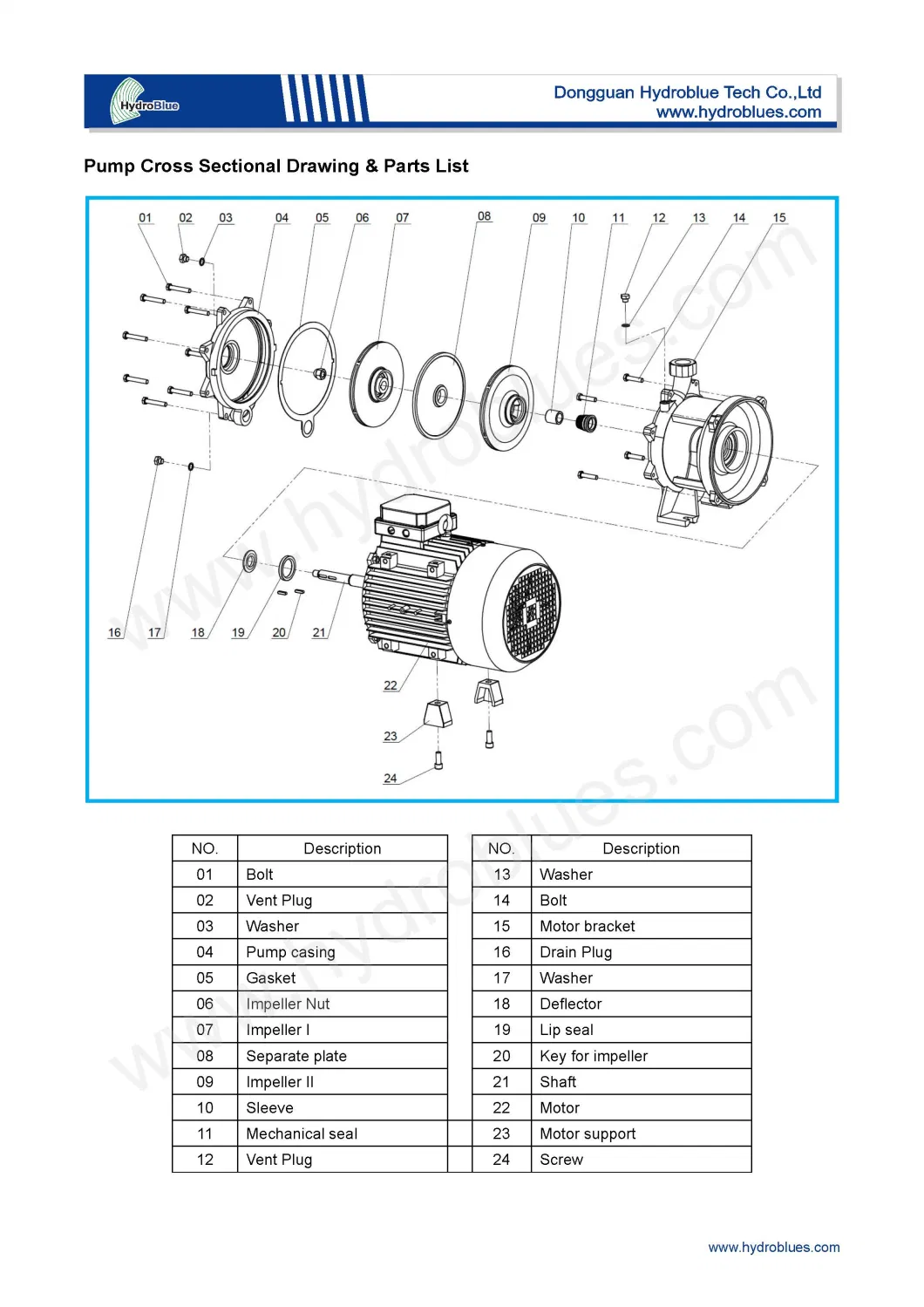

Materials Specifications for Pump Main Parts

Materials Specifications for Pump Main Parts

The close-coupled twin-impeller centrifugal electric pump is designed for the pumping of clean water or any clear liquids which do not contain solids and are not corrosive, abrasive or explosive when in contact with the pump motor unit and its working parts

Design Features

Monobloc / Close-coupled centrifugal electric pump, foot-mounted, Two-stage overhung pumps.

> Connection type: Female thread

> Casing structure: End suction, center radial discharge.

> Shaft seal: Single mechanical seal (Graphite / Ceramic / NBR / SS304), On request: Graphite / Silicon carbide / Viton / SS316.

> Driven shaft: Pump and motor flanged together to form a close-coupled unit, with common shaft.

> Axial force balance: Adopting impeller back-to-back configuration, effectively balancing axial force, reducing vibration and noise, and ensuring smoother operation of the electric pump.

Others

> Low maintenance costs.

> High operating reliability.

> Service-friendly design.

> Optimal tightness.

On Request

> Other operating voltages and frequencies

> Special mechanical seal; special liquids

> Special temperature

How to Read the Pump Model

| Pump model: SDPT 1500 | |

| SDPT | SDP: Two-stage High Pressure Electric Pump with single phase motor SDPT: Two-stage High Pressure Electric Pump with three phase motor |

| 1500 | Motor input power: 15HP x 100 |

The rotation of the pump rotor is clockwise looking from the motor to the pump.

Application

Water supply / Fire-fighting systems / Sprinkling / Irrigation / Drainage / Fire-fighting water / Domestic / Civil and industrial sectors

Close-coupled Two-stages, End-suction,

Centrifugal Electric Pumps

SDP Series Two-stage High Pressure Pump

APPLICATION:

> Water supply

> Fire-fighting systems

> Sprinkling

> Irrigation

> Drainage

> Fire-fighting water

> Domestic

> Civil and industrial sectors

> Water supply and transfer in municipal and industrial applications

SPECIFICATIONS:

> Pump Suct. Size: 1.5 inch to 2 inch

> Pump Disc. Size: 1.5 inch

> Capacity Q: 1.5 m3/h to 36 m3/h

> Head H: 50 m to 130 m

> Speed: 50Hz or 60Hz, VFD

> Motor power: 3 kW to 15 kW

Product Standard: ISO9908

Materials Specifications for Pump Main Parts

Materials Specifications for Pump Main Parts | Part Description | Materials Class | USA | Germany | Japan |

| AIS, ASTM | DIN | JIS | ||

| Casing | Cast iron | Class 25B | GG-20 | FC200 |

| Impeller | Cast iron | Class 25B | GG-20 | FC200 |

| Bronze | C83600 | G-CuSn5ZnPb | BC6 | |

| Shaft | Carbon steel | AISI1045 | C45 | S45C |

| Martensite Stainless steel | AISI420 | DIN1.4021 | SUS410J1 | |

| Welding austenitic Stainless steel | AISI304 | DIN1.4301 | SUS304 | |

| Motor bracket | Cast iron | Class 25B | GG-20 | FC200 |

| Bearing | China brand / NSK | |||

| Shaft seal | Graphite / Ceramic / NBR / SS304 On request: Graphite / Silicon carbide / Viton / SS316 | |||

COMPANY INTRODUCTION

Dongguan Hydroblue Tech Co.Ltd, setup in 2007, is known as a fast-growing provider for pumps, motors, sealing systems, couplings, gearboxes and engineering solutions. We are dedicated to provide customers with precise and reliable service by combining the manufacturing capability of mainland China with our supply chain management services through our extensive network of Chinese factories.

HydroBlue's vision is to provide our customers with the highest level of satisfaction imaginable by offering innovative solutions, nurturing long-term relationships, anticipating future needs and being highly responsive to their emergencies at the most cost effective basis.

Over the years, HydroBlue has established itself in Singapore,Malaysia,Indonesia,Thailand,

Russia, Belarus, Ukraine and China market, focusing more and more on oil and gas industry, mining, utilities and government sectors.

Dongguan Hydroblue Tech Co.Ltd, setup in 2007, is known as a fast-growing provider for pumps, motors, sealing systems, couplings, gearboxes and engineering solutions. We are dedicated to provide customers with precise and reliable service by combining the manufacturing capability of mainland China with our supply chain management services through our extensive network of Chinese factories.

HydroBlue's vision is to provide our customers with the highest level of satisfaction imaginable by offering innovative solutions, nurturing long-term relationships, anticipating future needs and being highly responsive to their emergencies at the most cost effective basis.

Over the years, HydroBlue has established itself in Singapore,Malaysia,Indonesia,Thailand,

Russia, Belarus, Ukraine and China market, focusing more and more on oil and gas industry, mining, utilities and government sectors.

HydroBlue Technical Advantages

Hydroblue Tech achievement is built by multiple sources. Its knowhow and capability is formed through close cooperation with China leading hydraulic institution--The Fluid Machinery Engineering and Technology Research Center of JIANGSU UNIVERSITY, and other machinery suppliers and engineering companies.

HydroBlue's Service

1.Calculation of pipeline loss

2.Reliable and precise pump model selection

3.Professional reverse-engineering for critical spare parts

4.Analysis for pump service data and results

5.Pump process supervision and control

Hydroblue Tech achievement is built by multiple sources. Its knowhow and capability is formed through close cooperation with China leading hydraulic institution--The Fluid Machinery Engineering and Technology Research Center of JIANGSU UNIVERSITY, and other machinery suppliers and engineering companies.

HydroBlue's Service

1.Calculation of pipeline loss

2.Reliable and precise pump model selection

3.Professional reverse-engineering for critical spare parts

4.Analysis for pump service data and results

5.Pump process supervision and control

HydroBlue's Products Range & Series

1.Water Treatment

Utter Water purification / Seawater Treatment / Concentration of Concentrated Salt-Zero Emission

1.Water Treatment

Utter Water purification / Seawater Treatment / Concentration of Concentrated Salt-Zero Emission

2.Sewage Treatment

City sewage treatment / Industrial sludge / Industrial sewage / Electronics industry / Electroplating, printing and dyeing

3.API610 Petroleum Industry

Petroleum, Petrochemical and Natural Gas Industries (Refinery, Petrochemical, Oil & Gas etc.)

4.Thermal Power Plant

Cooling / Circulation / Boiler feed water / Condensate water

5.Pulp Industries

Palm oil , Sugar, Pulp & Paper plant

6.Air Conditioning & Fire Fighting Engineering

Air Conditioning / Fire Fighting

7.Chemical Industry

Coating / Ceramics / Food processing / Pharma

8.Pump Station

Hydraulic engineering / Pump station

9.Replacement / Repair Spare Parts

10.Digital Intelligent Control Water Pump

9.Replacement / Repair Spare Parts

10.Digital Intelligent Control Water Pump

Q1: Are you a factory or a trading company?

A: Trading company

Q2: What're your payments?

A: L/C, T/T, D/P, PayPal, Western Union, Small-amount payment

Q3: What about package?

A: Standard exportation packaging with polywood box.

Q4: How about the delivery time?

A: 30~90 days, Depend on quantity and season.

Q5: How about the MOQ?

A: 1 set.

Q6: How about the quality guarantee?

A: One year after commissioning or 18 months after delivery.