- Overview

- Product Description

- Chart

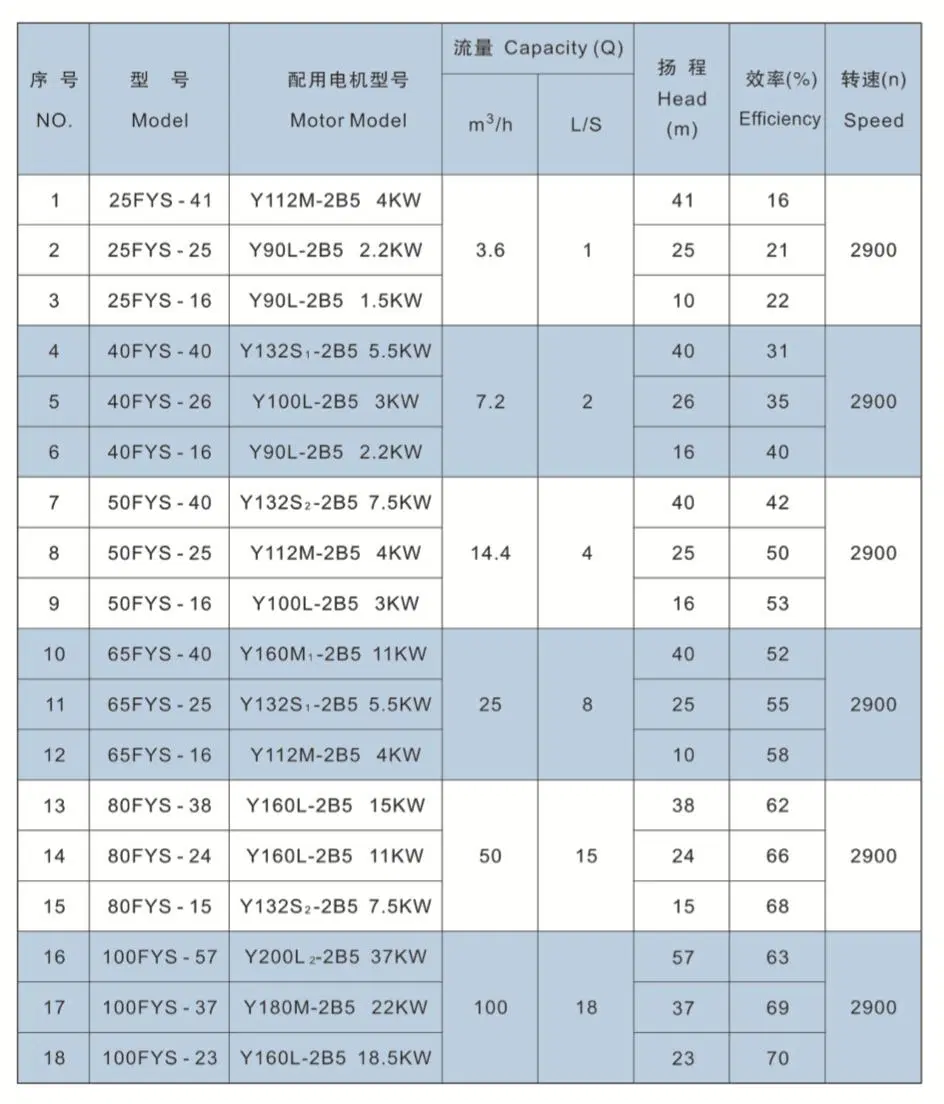

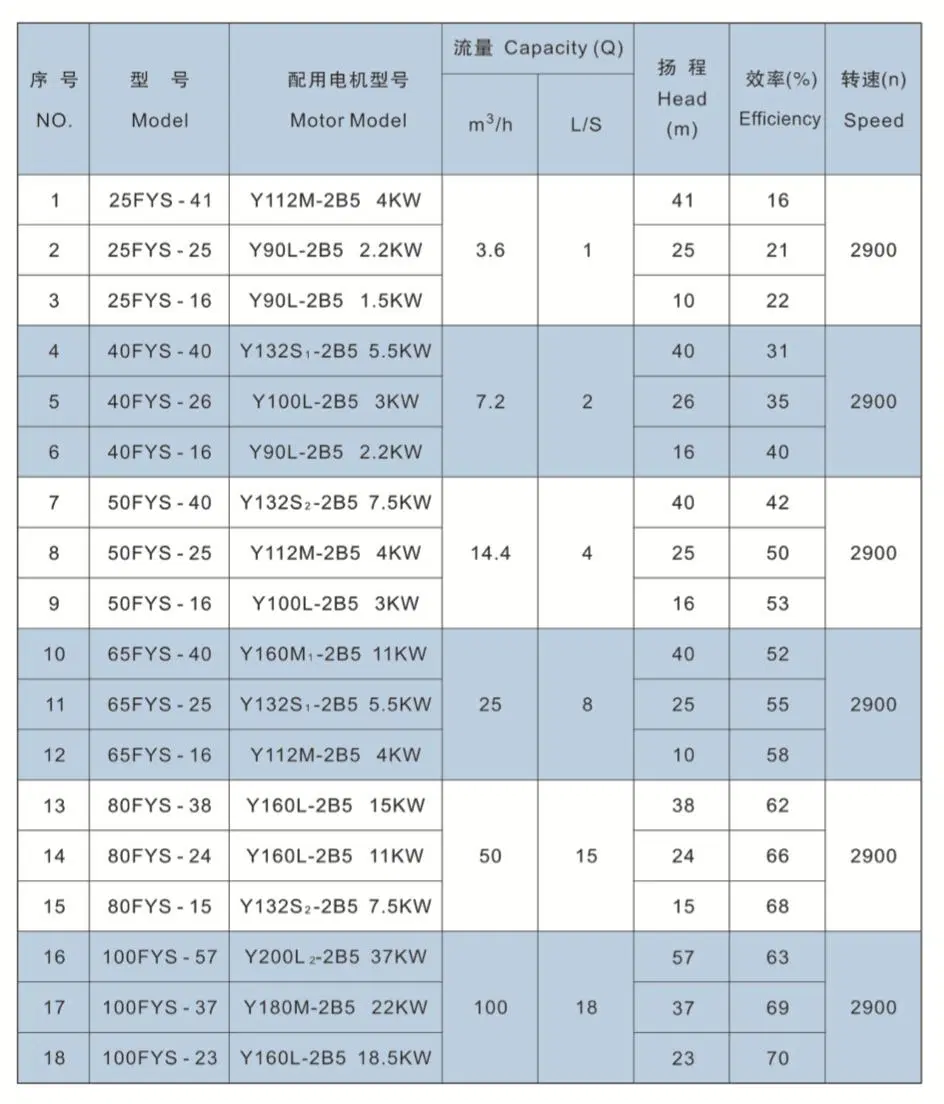

- Product Parameters

- Company Profile

- FAQ

Basic Info.

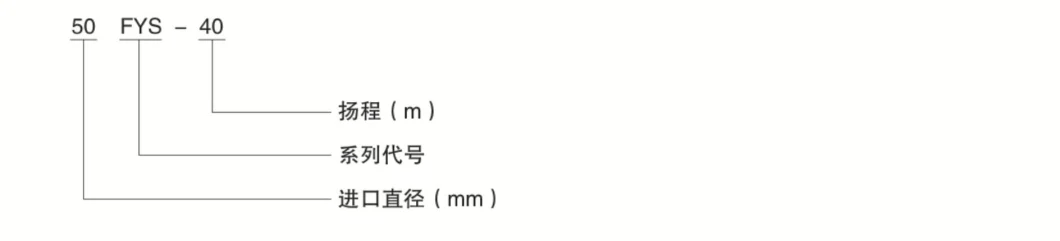

Model NO.

FYS

Position of Pump Shaft

Vertical Pump

Pump Casing Combined

Horizontal Split Pumps

Mounting Height

Suction Centrifugal

Impeller

Closed

Usage

Pump, Pumps, Condensate Pump, Circulating Pump, Vertical Pump

Temperature

-20~150degree

Transport Package

Plywood Box

Trademark

Feiyue/Kalen

Origin

Jiangsu, China

HS Code

841370

Production Capacity

5000

Product Description

Product Description

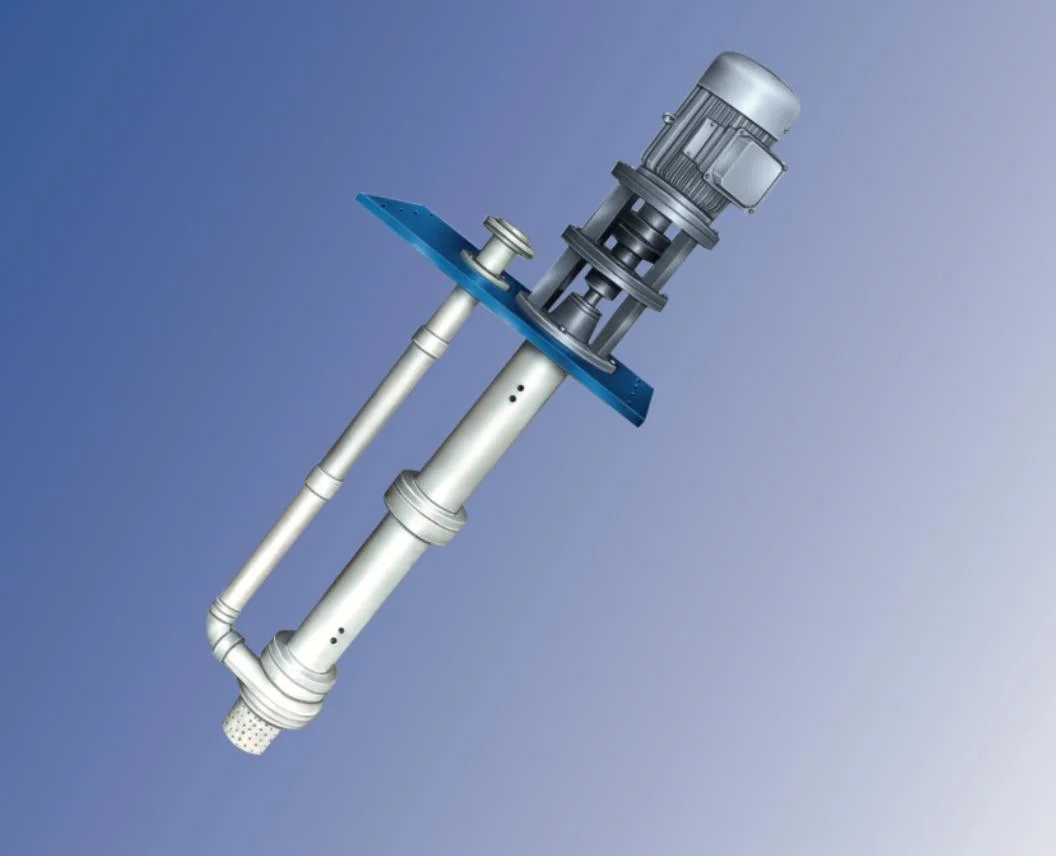

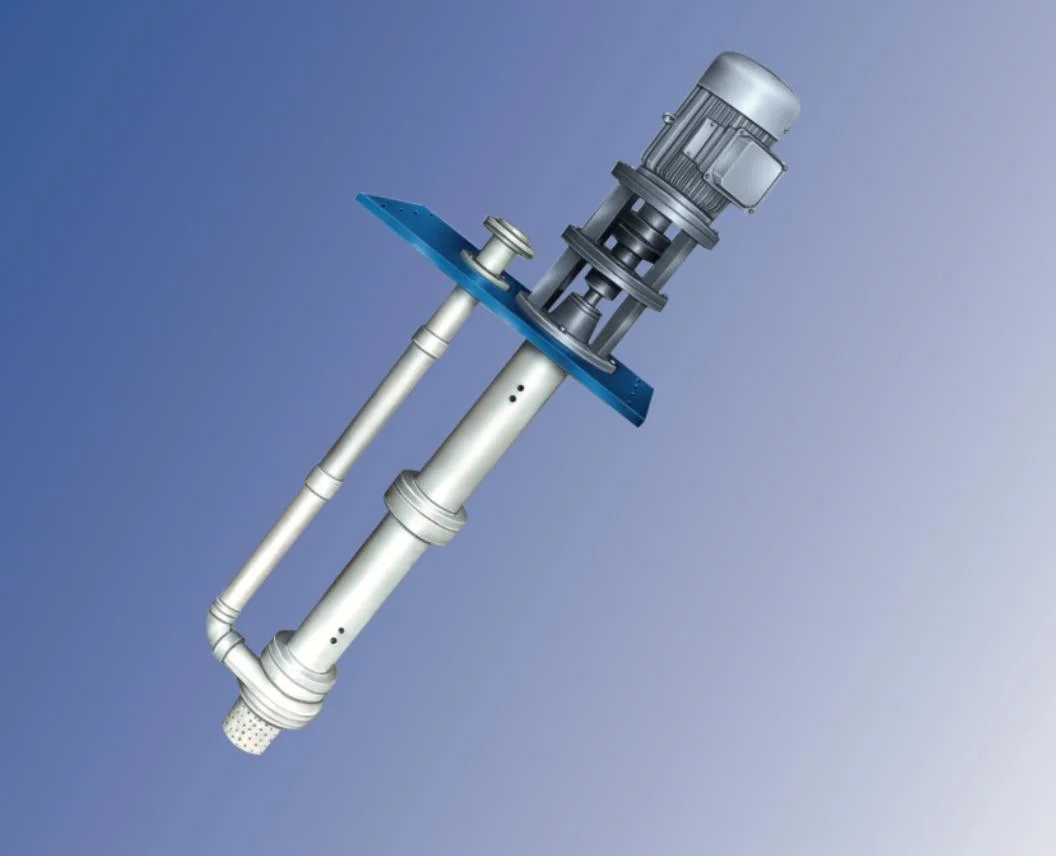

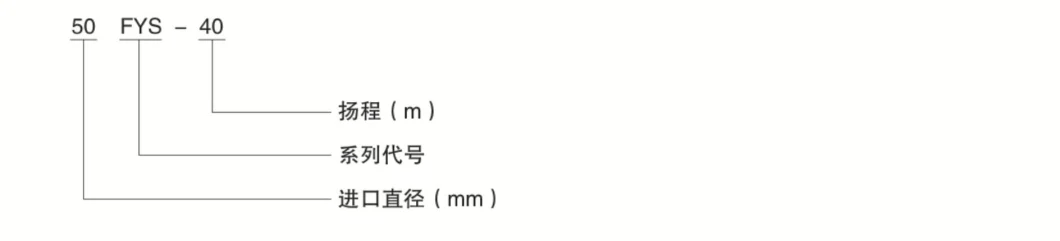

Fys Vertical Centrifugal Water Pump, Sump Pump,Fluoroplastic slurry pump for Chemical Purpose (VS4)

Conform to design standard of ISO2858/GB/T5656

Flow range: 3~400m3/h

Lift range: ~50m

Design pressure: ~1.0MPa

Application temperature: -20~150ºC

Application field: This series of pump is mainly used in industries of oil refinery, petrochemical industry, coal chemical industry, power plant, environmental protection engineering, polluted water treatment and cement plant, etc.

Suitable for transporting all kinds of clean, particle free or micro particle contained neutral or corrosive medium.

Flow range: 3~400m3/h

Lift range: ~50m

Design pressure: ~1.0MPa

Application temperature: -20~150ºC

Application field: This series of pump is mainly used in industries of oil refinery, petrochemical industry, coal chemical industry, power plant, environmental protection engineering, polluted water treatment and cement plant, etc.

Suitable for transporting all kinds of clean, particle free or micro particle contained neutral or corrosive medium.

General

FYS series chemical submerged pump is vertical single-stage single -suction centrifugal pump. It is used in transpor-ting cntaining no solid grain no crystal corrosive liquids (it can transport tiny crystal liquids for special made) whose te-mperature is from -20ºC to 150ºC . The operating parts are submerged in liquids, shaft seal has no leakage. It has adva-ntages such as small area, liable usage, convenience repair, strong anti-corrosive. It is widely used in chemical, med-ical and petro-chemical industry.

Product instruction

| 1 | Before the pump cover | 2 | Pump body | 3 | Impeller | 4 | Impeller nut | 5 | Pump cover | 6 | Shaft sleeve |

| 7 | Intermediate to take over | 8 | Liquid pipe | 9 | Middle of guide bearing | 10 | Axle | 11 | Floor | 12 | Bracket |

| 13 | On the collar | 14 | Bearing | 15 | Bearing box | 16 | Bearing | 17 | Coupling | 18 | Motor |

Performance parameters of the table