- Overview

- Product Description

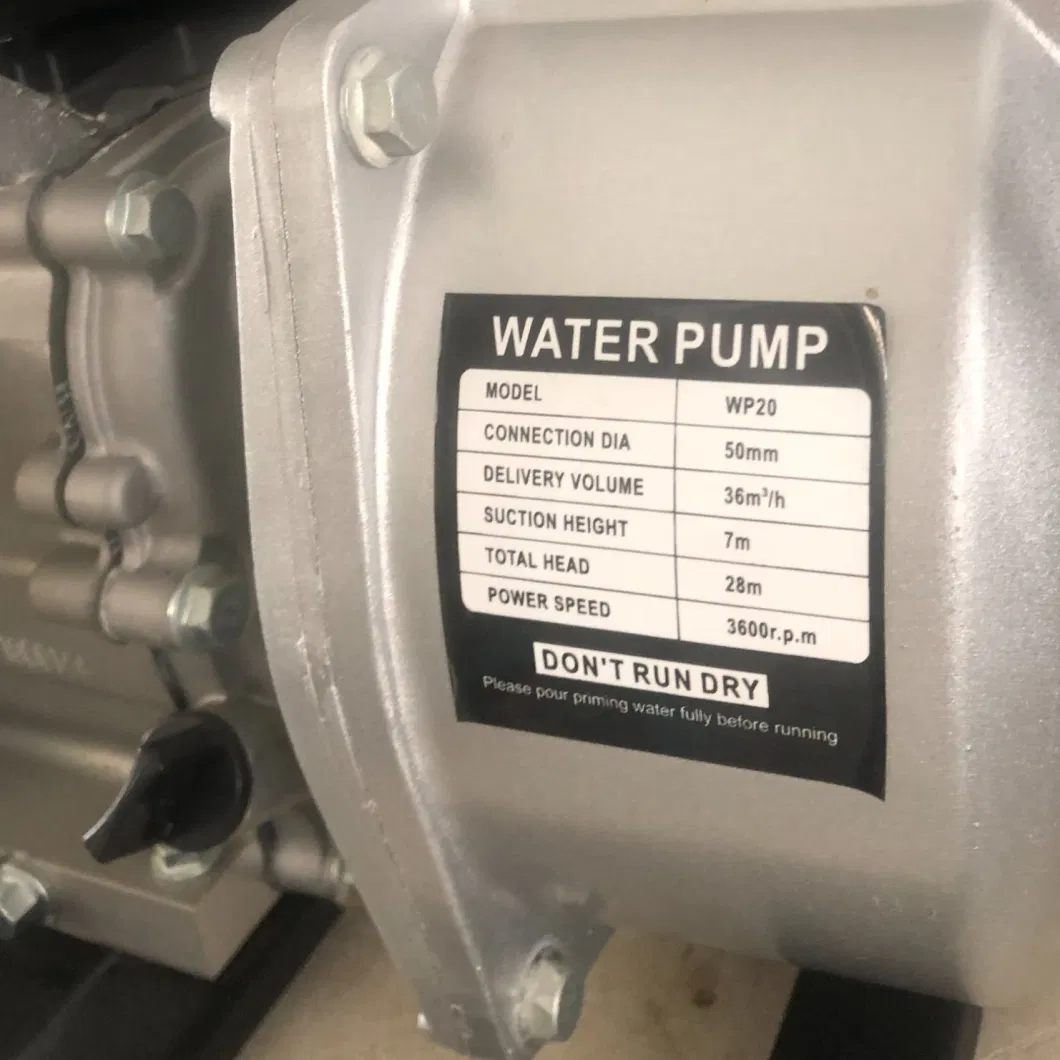

- Product Parameters

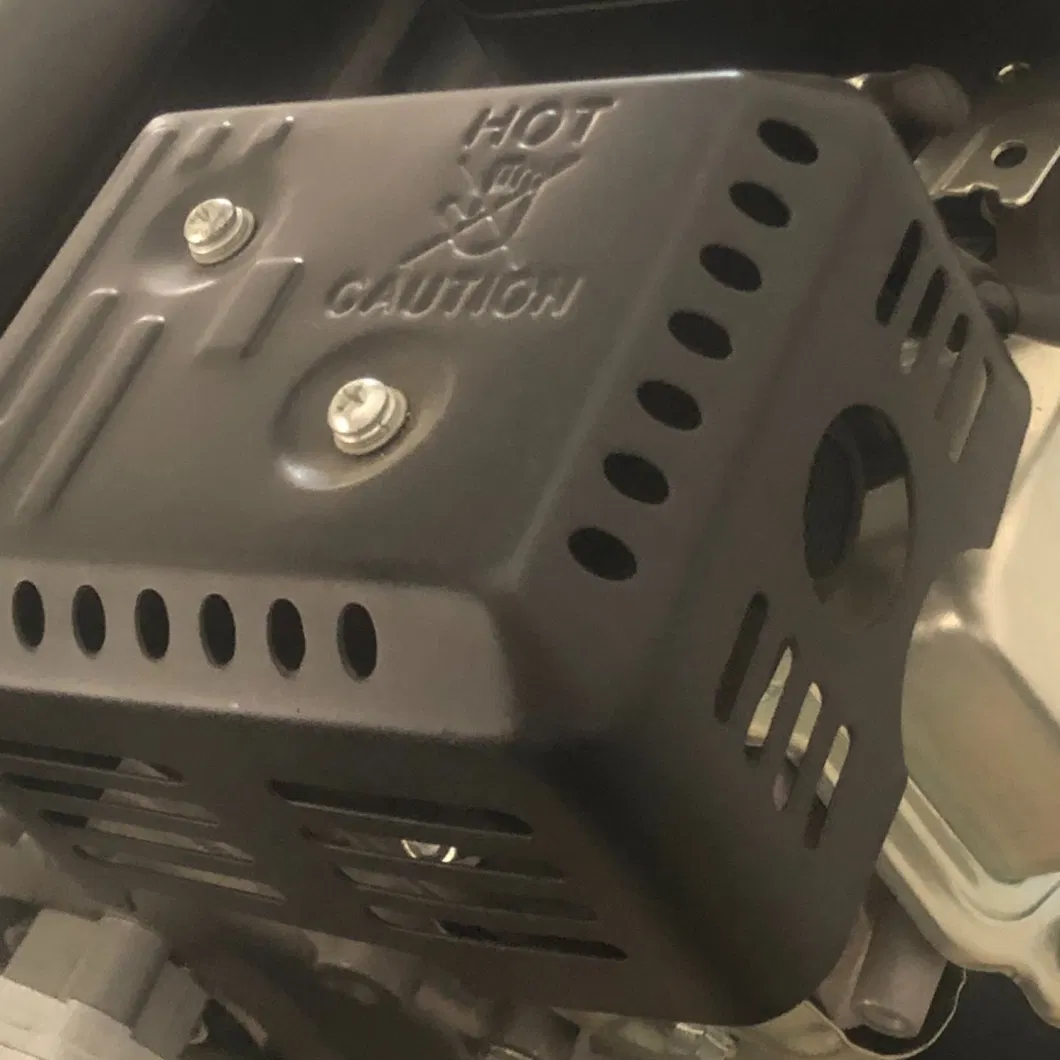

- Detailed Photos

- Packaging & Shipping

- Company Profile

- FAQ

- Installation Instructions

Basic Info.

Product Description

Our products have been exported to more than 50 countries and areas. Our main markets are in Europe, north America, south America, Africa, Middle East and Southeast Asia area etc.

Vision: Become the machinery company with the most reliable quality, the most professional technology, the most diverse products, and the best service.

All specifications can be discussed in detail, including sample price, MOQ, product price, shipping method, payment method etc.

| MODEL: | OK-WP20-25 | OK-WP20-25 | OK-WP20-30 |

| Inlet &Outlet Inside Dia.(inch) | 2.5/2inch | 2.5/3inch | 3.0/3inch |

| Pump Type | Cast Iron | ||

| Max Pump Lift(m) | 30 | 52 | 60 |

| Engine Model | OK168F | OK168-1F | OK200F |

| Displacement(cc) | 163 | 196 | 196 |

| Suction Height(m) | 5 | ||

| Max.Capacity(m³/hr) | 36 | 40 | 50 |

| Dimension(MM) | 515*395*440 | ||

| Net Weight(KG) | 23 | ||

| MODEL: | OK-WP20T | OK-W30T | OK-WP40T |

| Inlet&Outlet Diameter(mm) | 50/50 | 80/80 | 100/100 |

| Pump Type | Aluminum self Priming Pump | ||

| Max Lift Head(m) | 25 | ||

| Max Suction Height(m) | 7 | 6 | 5 |

| Engine Model | OK168F | OK168-1F | OK390F |

| Displacement(cc) | 196 | 196 | 68 |

| Fuel Tamk Capacity(L) | 3.6 | 3.6 | 6.5 |

| Dimension(MM) | 610*500*465 | 610*500*465 | 780*495*605 |

| Net Weight(KG) | 39 | ||

| MODEL: | OK-WP20C | OK-W30C | OK-WP40C |

| Inlet&Outlet Diameter(mm) | 2''(50mm) | 3''(80mm) | 4''(100mm)/3''(100mm) |

| Pump Lift(m) | 26 | 28 | 30 |

| Max delivery volume(m³/h) | 36 | 60 | 80 |

| Suction Height(m) | 8 | 7 | 6 |

| Engine Model | OK168F | OK168-1F | OK188F |

| Compression Ratio | 8:5:1 | ||

| Dimension(MM) | 485*385*380 | 515*395*440 | 590*465*660 |

| Net Weight(KG) | 26 | 28 | 32 |

1.Q: Are you a factory or trading company?

We are a factory with three large plants and we are the leading enterprise in the agricultural machinery industry.2.Q: Why should you buy from us, not from other suppliers?

Over the years, we have been focusing on the manufacture of advanced electrical and mechanical products.

With the goal to manufacture high-quality products.

3. Q: Whether you could make our brand on your products?

Yes. We can print your Logo on both the products and the packages if you can meet our MOQ.

4.Q: Whether you could make your products in our color?

Yes. The color of products can be customized if you can meet our MOQ.

5. Q: How to guarantee the quality of your products?

1) Always a pre-production sample before mass production.

2) Strict sampling inspection on products before shipment and intact product packaging ensured.

power end maintenance

1, must be checked before operation, control level. Plunger pump first run 50 hours, replace the lubricating oil must, after the replacement once every 200 hours.

2, all the screws must be tightened

3, the pump during operation, the lubricating oil temperature should not exceed 70 ° C, the medium temperature of not more than 55 ° C

4, the Shell grade lubricants can withstand S2G > 20

5, note the lubricating oil must be injected from the injection hole (remove vent cap is the oil hole), lubricating oil injection volume of approx. 18 litres

6, oil injection, must be approved by the 80 - 100 to the filter net, filter implantation. To prevent the impurities in the crankcase oil injection in vivo

7, observe the oil pump operation condition, the oil pressure of lubricating oil is maintained at 0.1 - 0.15MPa, oil can be observed from the transparent hose, oil of HERSHEY'S yellow transparent oily, poor gray opaque, black oil difference, under normal circumstances is black when it should be replaced

8, the lubrication system, the filter should be cleaned at any time over the network, if the filter oil filter must be damaged replacement

9, the replacement of lubricants, must be carried out in the hot state, the old oil on the net, at least once a year the old oil vent, crankshaft box must be clean to add new oil

Before 10, every oil change, should first check whether the water inlet part and resolved after the injection of new oil. Check the position of the middle rod: seals, seal, piston fillers

The connecting rod bolts in 11, always pay attention to the part of the pump connections, prevent faults

the fluid end maintenance

1, the suction and exclusion side screw

2, the packing box should be promptly replaced leakage seal

3, the protection of the plunger includes shall not be affected by any damage using piston cylinder. When not coated with anti rust oil protection screws from damage

4, pump head should be cleaned regularly suction filter;

5, work longer should adjust the sealing ring, check the valve seat on the check valve, spring is worn, replace if necessary

6, use special tool screwing the locking nut, is closely connected to check the piston and the middle rod, must pay close attention to

Seal

7, leakage should be replaced

8, the pump should be installed horizontally, before installation should be carefully check all parts, below the intact condition can be installed