Basic Info.

Model NO.

GLN250-8

Driving Type

Motor

Material

Cast Iron

Structure

Multistage Pump

Assembly

Condensate Water Pump

Power

Electric

Start Up

Electric Pump

Industry

Generator Set

Media

Condensate Water

Performance

High Efficiency

Theory

Centrifugal Pump

Merge

Changsha Swan

Merge2

Wuxi Pump Works

OEM/ODM

Accept

Media Temp

Below 80 Celsius

Direction of Rotation

Counterclockwise Viewed From Driven End

Capacity Range

120-2200m³/H

Head

36-360m

Speed

1480rpm

Transport Package

Export Plywood Case

Trademark

LEO

Origin

China

Production Capacity

3000set/Year

Packaging & Delivery

Package Size

1330.00cm * 1330.00cm * 5115.00cm

Package Gross Weight

2400.000kg

Product Description

General

GLN series high efficiency vertical multistage long shaft pump keeps high efficiency, good cavitations performance, rational structure, long operation life and easy and convenience maintenance and installation.

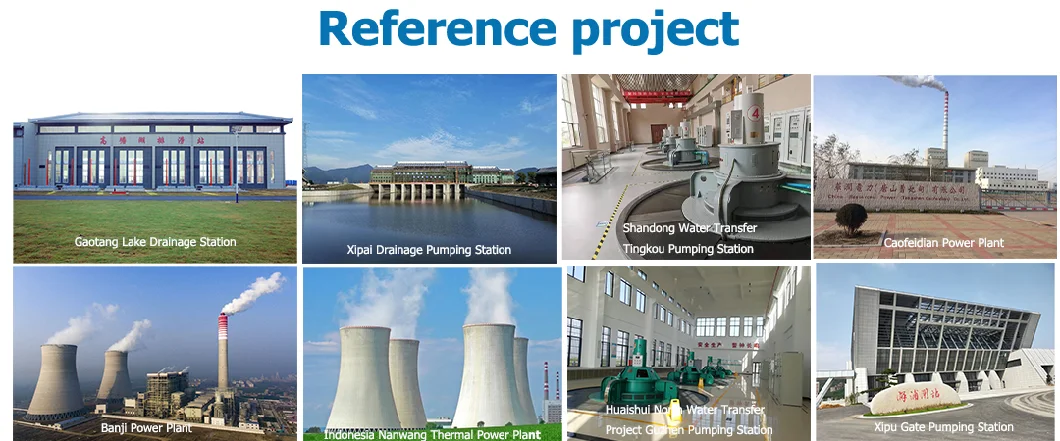

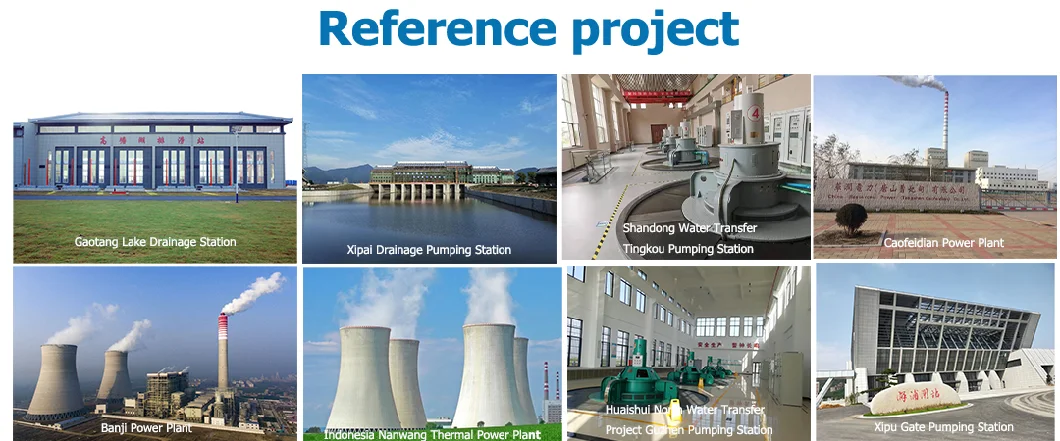

Application

The products are widely applied to condenser of 50-1000 MW generation set for delivering condensate water, and also applicable to water supply and drainage project which demands high suction performance, high efficiency and high head.

Performance Parameters Table

Product Attribute

Structural Feature

1.Construction

The construction has advantage of high efficiency, good cavitations performance, advanced construction, long operation life and convenience in installation disassembly (Patent no. ZL2 0092031162.5)

2.Seal

Single or double cartridge mechanical seal without any leakage while starting, running and stopping.

The seal has long operation life, convenience in assembly and disassembly, and simple maintenance.

3.Balance drum

Have marked results of axial force balancing, which is reliable, decrease load of thrust bearing and improve operation life.

Spiral seal construction is designed that leakage is small and volumetric efficiency is high.

4.Barrel casing

Complete negative pressure design that has good rigidity and stable operation.

Axial location is set for column pipe that prevent casing from horizontal swing and improve operation stability.

Guide vane is set on the bottom of column pipe that improve suction flow condition of first stage impeller, and further improve cavitations resist performance of pump.

5.Sleeve coupling

Patent technical (Patent no. ZL200820052182.7) of sleeve coupling with concentric reducer is adopted which have good centering function and convenience in assembly and disassembly.

6.Casing

Design of double discharge or three discharge spiral type flow channel is adopted that balance radial force, and make operation more stable.

Metal mould, accurate and digital machining are adopted that pump has steady flow velocity and low loss.

7.Thrust bearing part

Patent technique of thin oil self lubrication (Patent no. ZL200820052437.X), infuse oil online, sealing is stable without leakage.

Limits design in both send that avoid starting instant axial movement upward.

Heavy-duty bearing and water cooling construction are adopted that have long operation life.

Axial location of rotor can be adjusted, and set with online vibration and temperature monitoring devices.

8.Impeller, stage casing(diffuser)

Location design moved upward, close to driven end which improve rigidity of pump and may decrease vibration, and improve pump unit operation stability.

There is no back seal ring and balance hole designed for impeller which has high volumetric efficiency.

Radial diffuser is adopted for pump with mall capacity, and space diffuser is adopted for pump with big capacity that has high hydraulic efficiency.

9.Guide bearing

Polymers material adopted that friction coefficient is small, and have function of vibration absorption, and long operation life.

Sufficient groove for lubricating water is designed that have good cooling and lubricating.

Patent technical of location (Patent no. ZL200820052433.1) is adopted that without any loose, and assembly and disassembly is convenient.

10.Rotor part

Design thickened that have good rigidness and high critical speed.

Strictly balance tested that operation is more stable.

11.First stage impeller

Excellent double suction hydro model is adopted that have high efficiency and wide high efficiency range, and good cavitations performance.

Cavitations resist material is adopted for ensure good cavitations resist performance.

Metal mould, accurate and digital machining are adopted that pump have high efficiency.

FAQ

GLN series high efficiency vertical multistage long shaft pump keeps high efficiency, good cavitations performance, rational structure, long operation life and easy and convenience maintenance and installation.

Application

The products are widely applied to condenser of 50-1000 MW generation set for delivering condensate water, and also applicable to water supply and drainage project which demands high suction performance, high efficiency and high head.

Performance Parameters Table

| Model | Flow(m³/h) | Head(m) | Pump efficiency (%) | Shaft power (kW) | Speed(rpm) | Impeller outer diameter(mm) |

| GLN250-8 | 293.6 | 274.4 | 79.9 | 274.8 | 1480 | 295 |

Product Attribute

| Attribute | Attributes | Attribute value |

| Material | Impeller | ZG20Cr13 |

| Guide blade body | HT250 | |

| Thrust bearing | SKF/FAG | |

| Suction casing | Q235-B | |

| Suction bell,mechanical seal body,bearing body | HT250 | |

| First stage impeller | ZG07Cr19Ni10 | |

| Shaft | 40Cr | |

| Discharge casing,motor support,discharge elbow,barrel casing,column,Guide vane sleeve,seal ring | Q235-B | |

| Shaft sleeve,sleeve coupling,balance drum | 20Cr13 | |

| Balance drum | ZG230-450 | |

| Guide bearing | SXL/ZCu5Pb5Sn5 | |

| Working conditions | Medium temperature (ºC) | ≤80ºC |

| Running mode | Power frequency or frequency conversion | |

| Direction of rotation | counterclockwise | |

| Shaft seal cooling method | External demineralized water is connected before startup, after startup, the outlet is self-drafted for cooling | |

| Installation | Direction of rotation | counterclockwise |

| Thrust bearing form | The pump bears the thrust | |

| Pump thrust bearing lubrication method | Thin oil lubrication | |

| Structure type | Vertical can type | |

| Shaft seal | Cartridge mechanical seal | |

| Motor | Number of motor phases | 3 |

| Protection class | IP55 | |

| Insulation class | F | |

| Motor power(kW) | 355 | |

| Motor model | YKKL400-4/355KW/10KV/IP54/IC611/V1 | |

| Power frequency(Hz) | 50 | |

| Rated voltage(V) | 10000 | |

| Energy efficiency rating | 2 | |

| Motor speed | 1480 | |

| Bearing lubrication method | Thin oil lubrication | |

| Bearing lubrication and maintenance | Grease every 1500h | |

| Package | Pump weight(kg) | 4400 |

| Motor weight(kg) | 2630 |

Structural Feature

1.Construction

The construction has advantage of high efficiency, good cavitations performance, advanced construction, long operation life and convenience in installation disassembly (Patent no. ZL2 0092031162.5)

2.Seal

Single or double cartridge mechanical seal without any leakage while starting, running and stopping.

The seal has long operation life, convenience in assembly and disassembly, and simple maintenance.

3.Balance drum

Have marked results of axial force balancing, which is reliable, decrease load of thrust bearing and improve operation life.

Spiral seal construction is designed that leakage is small and volumetric efficiency is high.

4.Barrel casing

Complete negative pressure design that has good rigidity and stable operation.

Axial location is set for column pipe that prevent casing from horizontal swing and improve operation stability.

Guide vane is set on the bottom of column pipe that improve suction flow condition of first stage impeller, and further improve cavitations resist performance of pump.

5.Sleeve coupling

Patent technical (Patent no. ZL200820052182.7) of sleeve coupling with concentric reducer is adopted which have good centering function and convenience in assembly and disassembly.

6.Casing

Design of double discharge or three discharge spiral type flow channel is adopted that balance radial force, and make operation more stable.

Metal mould, accurate and digital machining are adopted that pump has steady flow velocity and low loss.

7.Thrust bearing part

Patent technique of thin oil self lubrication (Patent no. ZL200820052437.X), infuse oil online, sealing is stable without leakage.

Limits design in both send that avoid starting instant axial movement upward.

Heavy-duty bearing and water cooling construction are adopted that have long operation life.

Axial location of rotor can be adjusted, and set with online vibration and temperature monitoring devices.

8.Impeller, stage casing(diffuser)

Location design moved upward, close to driven end which improve rigidity of pump and may decrease vibration, and improve pump unit operation stability.

There is no back seal ring and balance hole designed for impeller which has high volumetric efficiency.

Radial diffuser is adopted for pump with mall capacity, and space diffuser is adopted for pump with big capacity that has high hydraulic efficiency.

9.Guide bearing

Polymers material adopted that friction coefficient is small, and have function of vibration absorption, and long operation life.

Sufficient groove for lubricating water is designed that have good cooling and lubricating.

Patent technical of location (Patent no. ZL200820052433.1) is adopted that without any loose, and assembly and disassembly is convenient.

10.Rotor part

Design thickened that have good rigidness and high critical speed.

Strictly balance tested that operation is more stable.

11.First stage impeller

Excellent double suction hydro model is adopted that have high efficiency and wide high efficiency range, and good cavitations performance.

Cavitations resist material is adopted for ensure good cavitations resist performance.

Metal mould, accurate and digital machining are adopted that pump have high efficiency.

FAQ

| 1. Q:Are you a manufacturer or trading company |

| A:We are a manufacturer that specializes in industrial pump for 60 years |

| 2. Q:What payment term do you prefer? |

| A:Normally we take payment term 30% T/T in advance,70% paid before shipment, we can also accept L/C at sight. |

| 3. Q:What about the package? |

| A:Standard export plywood case |

| 4. Q:How long is the warranty? |

| A: Eighteen (18) months after delivery, twelve (12) Months from the date of commissioning, whichever comes earlier |

| 5. Q:Is it acceptable to make customer's own brand? |

| A: Sure, we can do OEM & ODM |

| 6. Q:How many days does it take for manufacturing? |

| A: It depends on order quantity and pump types. Normally it takes 20-120 days |