Basic Info.

Model NO.

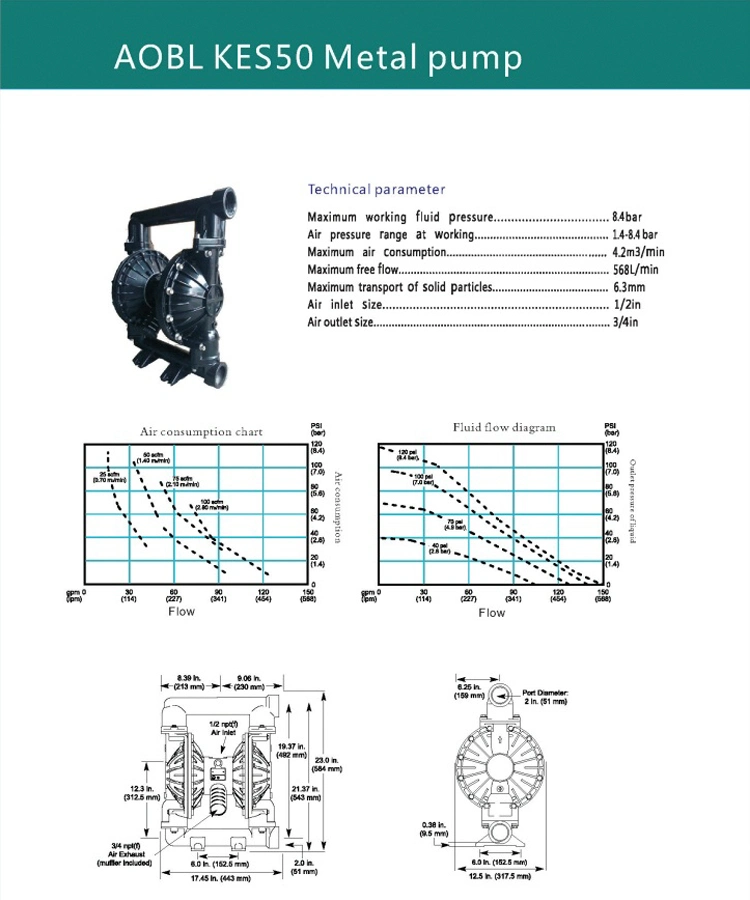

KES50

Function

Field Bus

Diaphragm Material

Nitrile Rubber

Performance

Explosion

Conveying Medium

Chemical Liquid

Transport Package

Standard Packing

Specification

Metal/Plastic

Trademark

Other

Origin

China

HS Code

8413501090

Production Capacity

500 Pieces/Month

Product Description

High Pressure Solvents Transfer Pneumatic Diaphragm Pump for Coating Industry

Product Introduction

AOBL pneumatic diaphragm pump has been widely used in the following areas:

* Water treatment: lime slurry, sewage, chemicals, wastewater, etc.

* Petrochemical Industry: crude oil, heavy oil, grease, mud, sludge, etc.

* Paint industry: resin, solvents, colorants, cleaning agents, paint, etc.

* Chemical industry: acid, alkali, solvent, suspension, dispersion, etc.

* Beverage industry: yeast, syrup, red wine, fruit juice, corn syrup, etc.

* Medical industry: solvent, acid, alkali, plant extracts, plasma and other types of drugs such as liquid, etc.

* Automotive Industry: polishing emulsion, oil, coolant, automotive primer, varnish, varnish additives, etc.

* Ceramic industry: mud, ceramic slurry, lime slurry, slurry, etc.

Material characteristics and selection of components for AOBL

Certificate

Company Profile

Packing & Shipping

FAQ

Q1: What's your business range?

A: We manufacture PH/ORP/EC/DO/Chlorine/Turbinity meter and provide dosing pump, diaphragm pump,dosing system, pressure instrument, flow meter, level meter, dosing system and so on.

Q2: How about the quality of the managements?

A: We have a complete quality control system , all of our products will be fully pre-inspection by QC departments before shipping to you . We have the certification of ISO,CE we could send the certification test of our company to you.

Q3: Can you offer OEM or design services?

A: Yes, we have our own design department and production tools. We can make OEM products according to your requirements.

Q4: What are your terms of payment and delivery time?

A: We could accept T/T, Paypal, Western Union, Credit Assurance. Generally, we will arrange the shipment within 7 days after received payment.

Q5: How about warranty?

A: 12 months warranty.

More information please contact us, we will provide the timely feedback!

Product Introduction

AOBL pneumatic diaphragm pump has been widely used in the following areas:

* Water treatment: lime slurry, sewage, chemicals, wastewater, etc.

* Petrochemical Industry: crude oil, heavy oil, grease, mud, sludge, etc.

* Paint industry: resin, solvents, colorants, cleaning agents, paint, etc.

* Chemical industry: acid, alkali, solvent, suspension, dispersion, etc.

* Beverage industry: yeast, syrup, red wine, fruit juice, corn syrup, etc.

* Medical industry: solvent, acid, alkali, plant extracts, plasma and other types of drugs such as liquid, etc.

* Automotive Industry: polishing emulsion, oil, coolant, automotive primer, varnish, varnish additives, etc.

* Ceramic industry: mud, ceramic slurry, lime slurry, slurry, etc.

Material characteristics and selection of components for AOBL

| Aluminum | Suitable for pneumatic motor and fluid cavity, strong impact resistance, wear resistance and heat resistance, medium resistance to chemical corrosion,high universality in addition to the HHCs fluid . |

| Polyvinylidene fluoride(PVDF) | Suitable for fluid body cavity and valve seat, strong resistance to chemical resistance, corrosion resistance, suitable for high purity acids. |

| Polypropylene(PP) | Suitable for pneumatic motor, fluid chamber and valve seat, moderate corrosion resistance, good chemical resistance, good versatility, especially suitable for ordinary acid and alkali. |

| Vition | Applicable to the diaphragm, ball valve and valve seat, strong acid resistance, resistance to unleaded fuel. |

| Stainless Steel | Applicable to the diaphragm, ball valve and ball seat, excellent corrosion resistance, suitable for water-based coating, viscous fluid. |

| nodular cast iron(CI) | Applicable to flow cavity, good corrosion resistance, suitable for conveying mud filter. |

| Santoprene | Suitable for diaphragm, ball valve and valve seat, good corrosion resistance, chemical resistance and heat resistance, not suitable for solvent, can replace the EPDM/EPR material. |

| PTFE | Suitable for diaphragm, ball valve and valve seat, good resistance to chemical, solvent resistance,medium resistance to corrosion, strong commonality. |

Certificate

Company Profile

Packing & Shipping

FAQ

Q1: What's your business range?

A: We manufacture PH/ORP/EC/DO/Chlorine/Turbinity meter and provide dosing pump, diaphragm pump,dosing system, pressure instrument, flow meter, level meter, dosing system and so on.

Q2: How about the quality of the managements?

A: We have a complete quality control system , all of our products will be fully pre-inspection by QC departments before shipping to you . We have the certification of ISO,CE we could send the certification test of our company to you.

Q3: Can you offer OEM or design services?

A: Yes, we have our own design department and production tools. We can make OEM products according to your requirements.

Q4: What are your terms of payment and delivery time?

A: We could accept T/T, Paypal, Western Union, Credit Assurance. Generally, we will arrange the shipment within 7 days after received payment.

Q5: How about warranty?

A: 12 months warranty.

More information please contact us, we will provide the timely feedback!