Basic Info.

Model NO.

MG0.60D57Y0.18KW4P

Type

Miniature Pump

Applications

Inkjet Printer/Sand Mill/Grinding/Auto Filling

Certification

CE, ISO

Motor Power

180 W

Pressure

0.6 MPa

Rated Current

0.6 a

Imp&Exp Size

G1/8

Viscosity

0.2-1500 Cps

Ambient Temperature

-40ºC - 110ºC

Rated Frequency

50Hz

Flow Rate

43.2 - 100.8 L/H

Working System

Continuous or Intermittent Operation

Pump Body

Stainless Steel with Titanium Nitride Coating

Gear

Tungsten Steel

Transport Package

Standard Export Carton or OEM Packing

Specification

5.13 KGS

Trademark

Macxi

Origin

Suzhou City, Jiangsu Province, China

HS Code

8413609090

Production Capacity

3000 PCS/Month

Product Description

Product Instruction:

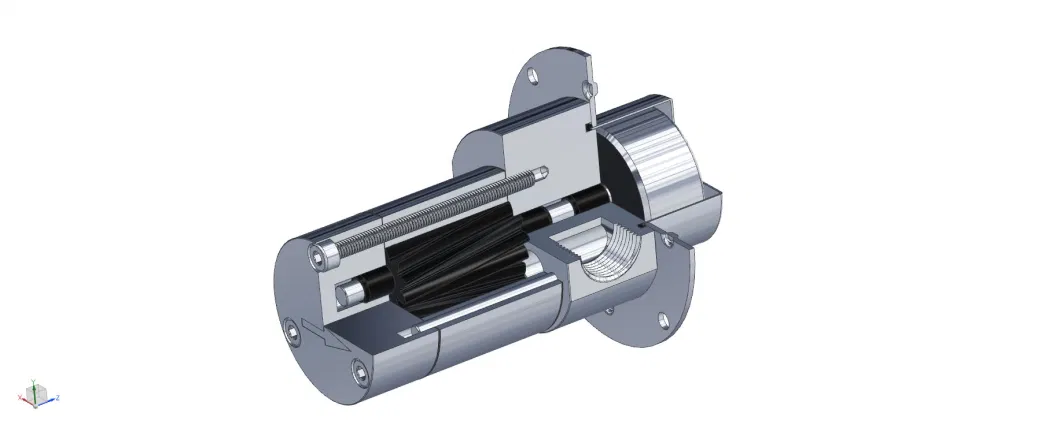

AC asynchronous motor is used as the power to drive the gear pump to work. The speed is constant and the torque is large. It can work stably for a long time. It is easy to use and has low maintenance cost. The flow can be adjusted by the frequency converter. If used in flammable and explosive places, explosion-proof motor should be selected.

The gear of the gear pump is made of tungsten steel, and the surface of the pump body is hardened by tin coating, so that the pump can provide excellent pumping performance and longer service life in the application of abrasive liquid (such as pigment paint and pigment ink).

2.Before using, squeeze in a small amount of medium to lubricate the gear from the gear pump inlet.

Product Model Selection Instruction:

Notes:

1. Pump output volume: 0.07,0.15,0.3,0.6,0.9,1.5,3.0,6.,12.0 (Unit: ml/rev)

2."S" means pump body material is 316L, gear and shaft sleeve are PEEK, seal with PTFE, the rest others are 316L.

"T" means pump body material is 316L, gear and shaft are Tungsten steel, shaft sleeve is PEEK, seal with PTFE, the rest others are 316L.

"P" means pump body material is PPS, gear materail and shaft sleeve are PEEK, seal with FFKM, the rest others are Hastelloy.

"H" means the pump body materials is Hastelloy, the gear and shaft sleeve is PEEK, the seal materials is PTFE, the rest of the pump flow material is Hastelloy, the appearance and size is same as 316L pump, details product parameters refer to 316L pump head.

3. Pump head range: 57, 72, 88. Model 57 has 0.07,0.15,0.3,0.6,0.9,1.5 ml/rev;Model 72 has 1.5,3.0 ml/rev;Model 88 has 3.0,6.0,12.0 ml/rev.

4.Motor:HS: Stepper Motor; BL: External drive DC brushless; BLa:Built-in drive DC brushless; BLb:Built-in drive DC brushless (potentiometer)DC:Brush motor; Y:Common asynchronous motor; YB:Explosion proof asynchronous motor; SM:Servo motor YP: General asynchronous frequency conversion YBP: Explosion proof asynchronous frequency conversion, SMP: Servo frequency conversion.

Product Model : M0.60T57Y0.18KW

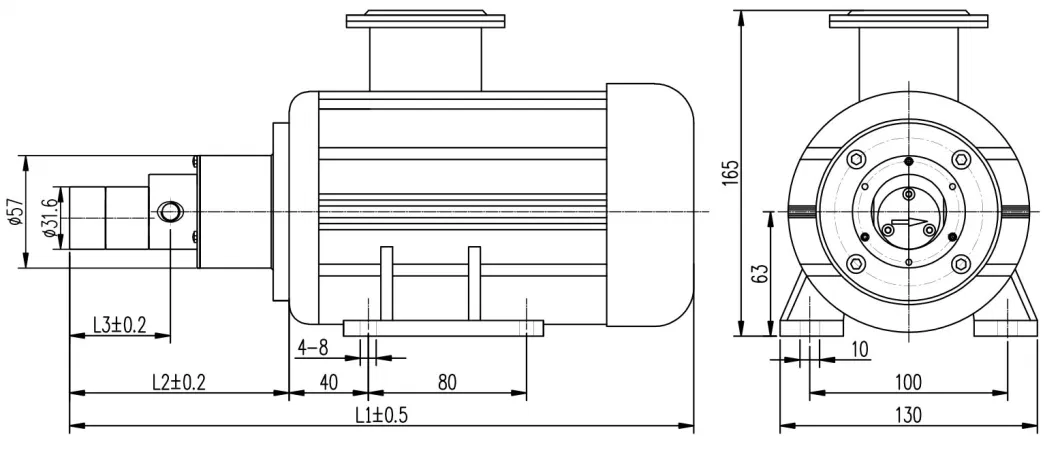

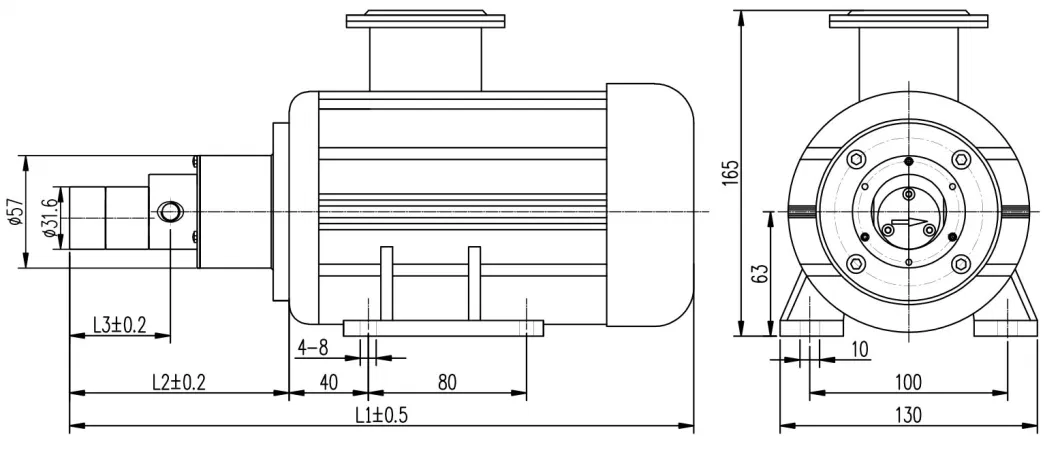

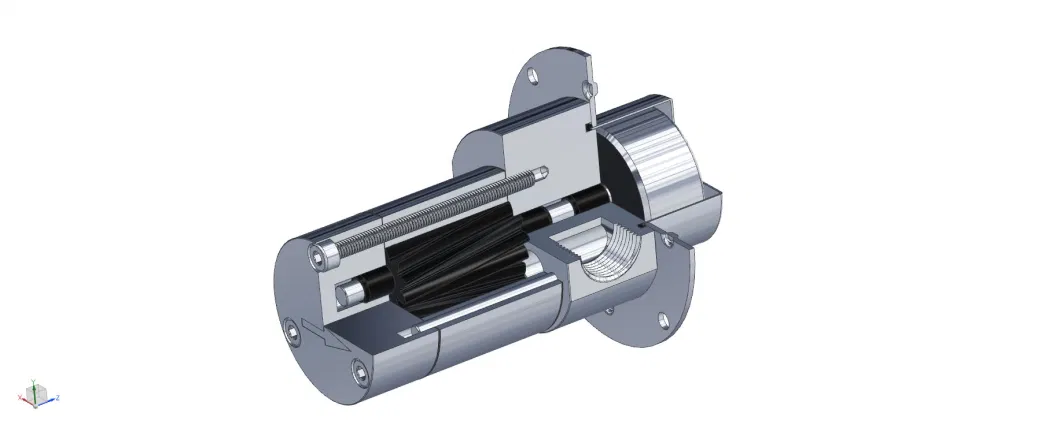

Product Diagram:

Product Parameters:

The values in this table are for reference only.

Remarks:

OEM service are avaiable according to your request.

The specifications are only for reference, for details checking, please feel free to contact us.

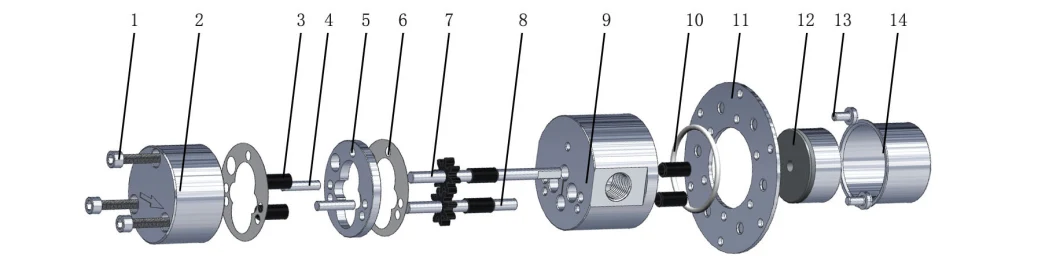

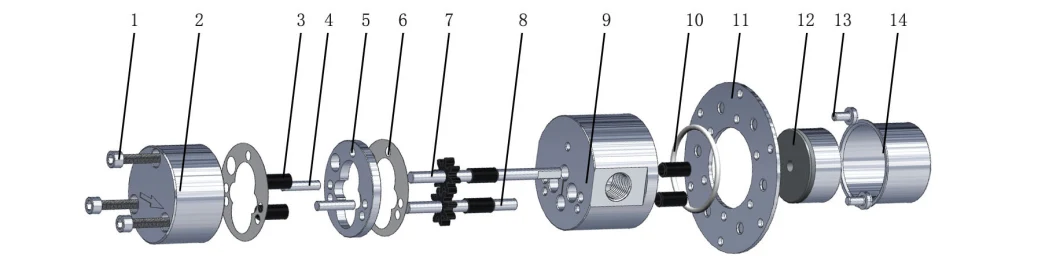

Pump head structure diagram:

1. Inner-hexagon screw*3 5. Pump body 9. Rear cover 13. Countersunk head screw*3

2. Front cover 6. Tef/lon gasket*2 10. O-ring 14. Isolation cover

3. Shaft sleeve*6 7. Driving gear 11. Platen

4. Pin*2 8. Driven gear 12. Internal magnetic steel

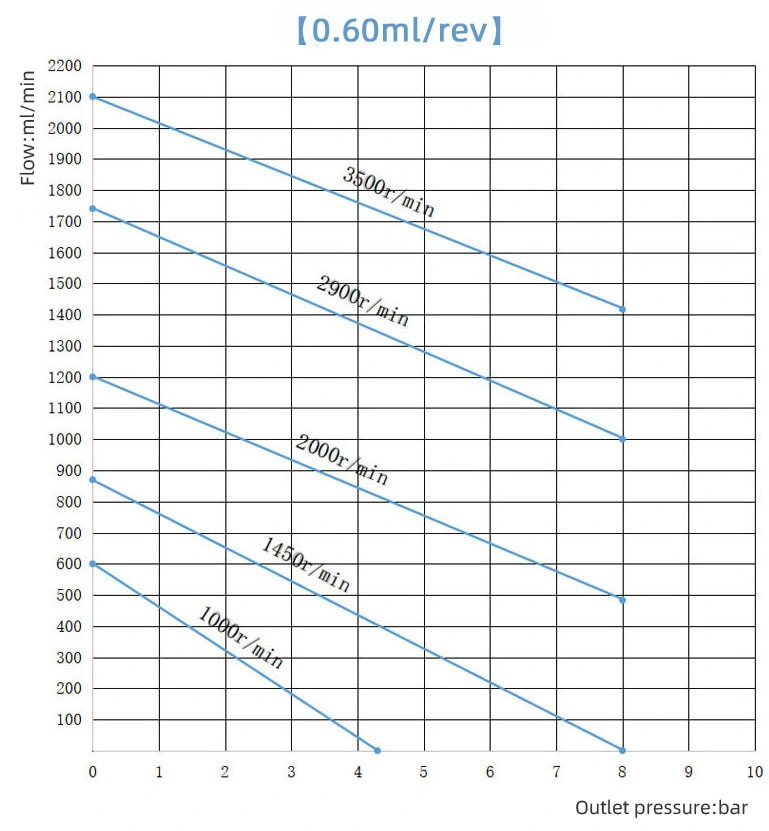

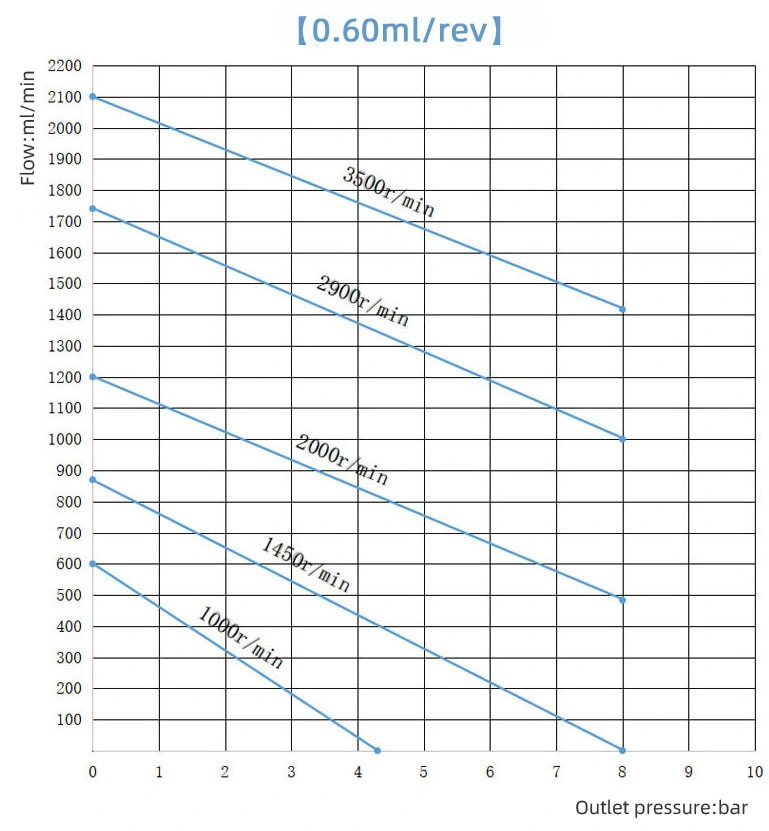

Product characteristic diagram:

Product Characteristics:

No pulse, high precision.

the external gear design makes the pump flow relatively unaffected by the system pressure,and the flow output has no pulsation, which can accurately measure the flow, and has strong repeatability.

Stable transmission.

Gear transmission can ensure constant instantaneous transmission ratio.

Zero leakage.

no packing seal or mechanical seal, no wearing parts, using magnetic drive, static seal,truly achieve zero leakage.

Corrosion resistance.

304 / 316L, Hastelloy and engineering plastics can be selected as pump body materials,which can be used in most chemical media.

Efficient and convenient, long service life.

adopt the way of motor direct drive, reduce the vulnerable parts. High efficiency and energy saving, simple maintenance, low installation cost, long service life.

Applicability.

suitable for high differential pressure, high system pressure and wide range of medium viscosity.

long service life.

The magnetic drive design of the non dynamic seal makes the shaft end no longer need the dynamic seal, which ensures the leakage free operation of the pump. The solid and stable shaft support can ensure the accurate meshing of the gear when the pump is running at high speed, ensure the smooth operation of the pump, the high accuracy of metering and the long service life of the pump.

Diversified drive mode.

magnetic drive gear metering pump can be directly connected with DC brushless motor,2-pole and 4-pole AC motor without reducer. The flow control of the pump can be realized by the controller of AC, DC, brushless DC and other motors. We can provide a variety of standard driving methods to meet the needs of customers.

A wide range of applications.

magnetic drive gear pump in the design, manufacture and application of a large number of use of magnetic drive, pump and motor technology. It has the advantages of no pulsation, long life and no leakage. These advantages make our products widely used in chemical, medical, laboratory, water treatment, food and other industries.

Applicable conditions:

All kinds of liquids, high precision fluid transportation, high repeatability, continuous small flow without pulsation.

It is used in aviation equipment, aircraft, spacecraft, chemical laboratory, chemical reagent adding, film manufacturing, pharmaceutical machine equipment, various lasers, micro cooling device of sighting instrument,tobacco flavoring adding, inkjet printing machine manufacturing, inkjet printer manufacturing, high-performance color printing machine and other industries.

Attentions:

1.400 Mesh filter shall be installed at the inlet of gear pump.2.Before using, squeeze in a small amount of medium to lubricate the gear from the gear pump inlet.

Product Model Selection Instruction:

| Pump Head | Motor | ||||

| M | 0.07 | S | 57 | BL | 120W |

| "M" means by magnetic drive | Pump revolution, Unit: ml/rev, note 1 for details | Pump body materials, note 2 details | Pump head spec, Unit: mm, note 3 | Motor Type, Note 4 | Motor Power |

1. Pump output volume: 0.07,0.15,0.3,0.6,0.9,1.5,3.0,6.,12.0 (Unit: ml/rev)

2."S" means pump body material is 316L, gear and shaft sleeve are PEEK, seal with PTFE, the rest others are 316L.

"T" means pump body material is 316L, gear and shaft are Tungsten steel, shaft sleeve is PEEK, seal with PTFE, the rest others are 316L.

"P" means pump body material is PPS, gear materail and shaft sleeve are PEEK, seal with FFKM, the rest others are Hastelloy.

"H" means the pump body materials is Hastelloy, the gear and shaft sleeve is PEEK, the seal materials is PTFE, the rest of the pump flow material is Hastelloy, the appearance and size is same as 316L pump, details product parameters refer to 316L pump head.

3. Pump head range: 57, 72, 88. Model 57 has 0.07,0.15,0.3,0.6,0.9,1.5 ml/rev;Model 72 has 1.5,3.0 ml/rev;Model 88 has 3.0,6.0,12.0 ml/rev.

4.Motor:HS: Stepper Motor; BL: External drive DC brushless; BLa:Built-in drive DC brushless; BLb:Built-in drive DC brushless (potentiometer)DC:Brush motor; Y:Common asynchronous motor; YB:Explosion proof asynchronous motor; SM:Servo motor YP: General asynchronous frequency conversion YBP: Explosion proof asynchronous frequency conversion, SMP: Servo frequency conversion.

Product Model : M0.60T57Y0.18KW

Product Diagram:

| Pump Model | Motor Type | Motor Base | L1(mm) | L2(mm) | L3(mm) | Pressure(bar) | Weight (kg) | Imp.&Exp. Size | Rated Flow(L/H) | |

| 2 Pole | 4 Pole | |||||||||

| M0.15T57 | Y0.18KW | 63 | 298.2 | 93.7 | 33.5 | 8 | 5.07 | G1/8 | 25.2 | 12.6 |

| M0.30T57 | 298.2 | 93.7 | 33.5 | 5.07 | 50.4 | 25.2 | ||||

| M0.60T57 | 302.4 | 97.9 | 37.7 | 5.08 | 100.8 | 50.4 | ||||

| Pump Head Parameter | Motor Parameter | ||

| Continuous work pressure | 0.6MPa | Rated Power | Three-Phase 380V/220V |

| Fluid Viscosity | 0.2-1500cps | Rated frequency | 50HZ |

| Ambient Temperature | -40ºC-110ºC(If the temperature of the conveying medium is over 70 °C, please make a special request.) | Rated Current | 0.6A |

| Static sealing | PTFE | Protection Level | IP55 |

| Pump Body material | Stainless steel with Titanium nitride coating | Working system | Continuous |

| Gear Material | Gear and gear shaft are made of tungsten steel | ||

Remarks:

OEM service are avaiable according to your request.

The specifications are only for reference, for details checking, please feel free to contact us.

Pump head structure diagram:

1. Inner-hexagon screw*3 5. Pump body 9. Rear cover 13. Countersunk head screw*3

2. Front cover 6. Tef/lon gasket*2 10. O-ring 14. Isolation cover

3. Shaft sleeve*6 7. Driving gear 11. Platen

4. Pin*2 8. Driven gear 12. Internal magnetic steel

Product characteristic diagram:

Product Characteristics:

No pulse, high precision.

the external gear design makes the pump flow relatively unaffected by the system pressure,and the flow output has no pulsation, which can accurately measure the flow, and has strong repeatability.

Stable transmission.

Gear transmission can ensure constant instantaneous transmission ratio.

Zero leakage.

no packing seal or mechanical seal, no wearing parts, using magnetic drive, static seal,truly achieve zero leakage.

Corrosion resistance.

304 / 316L, Hastelloy and engineering plastics can be selected as pump body materials,which can be used in most chemical media.

Efficient and convenient, long service life.

adopt the way of motor direct drive, reduce the vulnerable parts. High efficiency and energy saving, simple maintenance, low installation cost, long service life.

Applicability.

suitable for high differential pressure, high system pressure and wide range of medium viscosity.

long service life.

The magnetic drive design of the non dynamic seal makes the shaft end no longer need the dynamic seal, which ensures the leakage free operation of the pump. The solid and stable shaft support can ensure the accurate meshing of the gear when the pump is running at high speed, ensure the smooth operation of the pump, the high accuracy of metering and the long service life of the pump.

Diversified drive mode.

magnetic drive gear metering pump can be directly connected with DC brushless motor,2-pole and 4-pole AC motor without reducer. The flow control of the pump can be realized by the controller of AC, DC, brushless DC and other motors. We can provide a variety of standard driving methods to meet the needs of customers.

A wide range of applications.

magnetic drive gear pump in the design, manufacture and application of a large number of use of magnetic drive, pump and motor technology. It has the advantages of no pulsation, long life and no leakage. These advantages make our products widely used in chemical, medical, laboratory, water treatment, food and other industries.

Applicable conditions:

All kinds of liquids, high precision fluid transportation, high repeatability, continuous small flow without pulsation.

It is used in aviation equipment, aircraft, spacecraft, chemical laboratory, chemical reagent adding, film manufacturing, pharmaceutical machine equipment, various lasers, micro cooling device of sighting instrument,tobacco flavoring adding, inkjet printing machine manufacturing, inkjet printer manufacturing, high-performance color printing machine and other industries.

| Industrial machinery and equipment | Water treatment | Food and cosmetics |

| Inkjet printing/painting | Mask making | Food and Beverage filling |

| Oil transportation | Booster pressure | Filling of perfume cosmetics |

| Sand mill/Grinding | Circulating cooling | Quantitative Transport |