Basic Info.

Screw Suction Method

Single Suction

Pump Shaft Position

Horizontal

Performance

Wearable

Application

Sewerage Treatment, Food, Chemical

Certification

CE, ISO, RoHS

Material

Cast Steel,SS304,SS316,Stainless Steel

Stator Material

NBR,FPM,EPDM, Food Grade Rubber

Motor

Ye3 Normal,Explosion-Proof Motor

Number of Stages

One, Two, Multistage

Capacity

0.5-300m³/H

Pressure

0-5MPa

Inlet / Outlet

20-500mm

Speed

50-1500rpm

Viscosity

1-1000000cst

Voltage

380V or as Require

Frequency

50Hz,60Hz

Max Temperature

150ºC

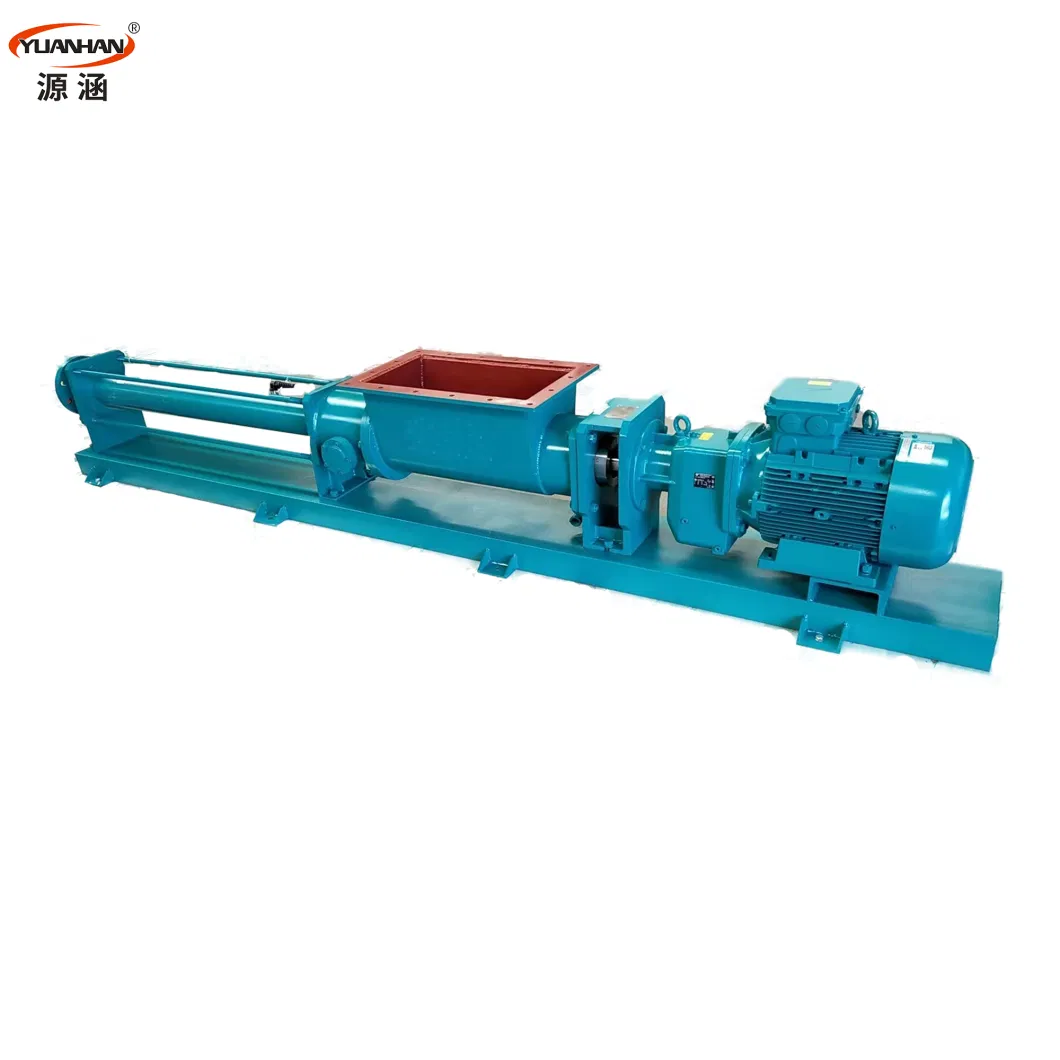

Mono Screw Pump

Cast Iron, Stainless Steel

Mini Helical Single Screw Pump

Feed Screw Pump

Hopper Mono Screw Pump

Open Hopper Pump, Large Opening Feed Screw Pump, C

Transport Package

Angle Steel Frame Supports Seaworthy Wooden Case

Specification

0.1-500m3/h

Trademark

yuanhan

Origin

China

HS Code

8413604090

Production Capacity

10000set/Year

Product Description

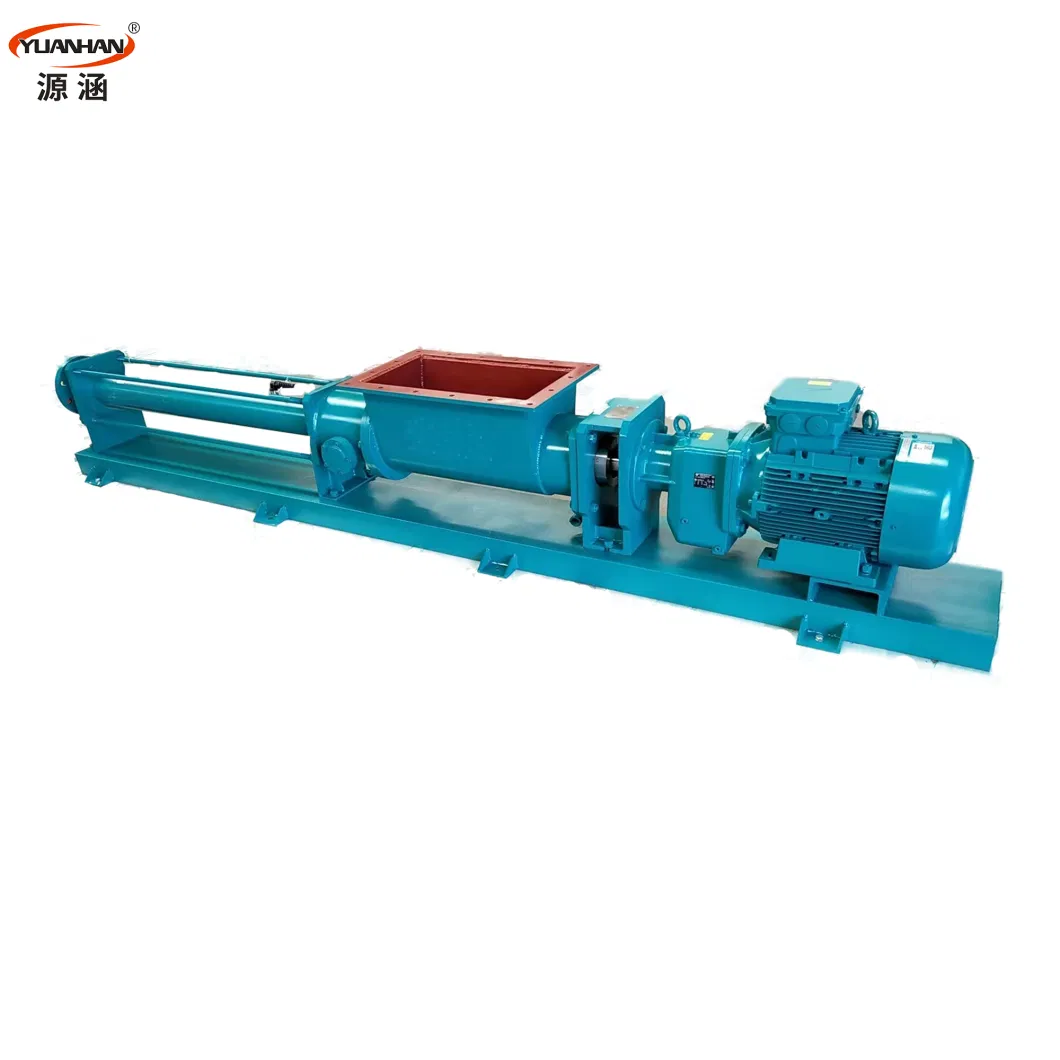

High Viscosity Liquid Positive Displacement Rotary Progressive Cavity Single Screw Pump

Product Description

Sinlge screw pump features:

The eccentric pump is a screw pump sealed on the inside gearing, belong to rotor displacement pump. The essential part consists of combination of a stator with two-start female thread and a rotor with single-start screw. When the driving shaft causes the rotor in planetary motion by the universal coupling, between the stator and the rotor, being in mesh continually, formed many spaces. As these spaces unchanged in voiume are axial moving, the medium handled is transmited to the outlet port from the inlet port. The liquid transmited to get not confused or disruptive, thus it is the most suitable for liffing mediums containing solid matter. abrasive particles and viscous liquids.

Performance data:

Viscosity: 1.0~ 1500 mm2/s, the viscosity can reach up to 3000000 mm2/s when reduced the speed.

Flow range: 1~ 500 m³/h;

Maximum pressure: 4.0 Mpa;

Max. Temperature: 150ºC

Horizontal Mounting/Vertical mounting

This is part of the parameters, subject to the actual order.

Features:

The coupling rod terminates at both ends in pin type universal joints,The pin and bushing are made of special metal, the durability of the joint is improved greatly. Simple construction. easy and quick to dismantle(Fig.l). Stator provided at both ends with external collars vulcanized to it, which provide a safe seal to the suction and discharge section. It protect the stator casing against corrosion. Between the suction casing and bearing housing is stiuated an inter changeable housing for a suiffing box or mechanical seal(pumps can be converted retrospectively to a different type of seal). PN pump's suction-, discharge-connections with threaded connection:according to DIN 1187-A as a standard. Thus, a quick disassembly of pipe and hose connections on suction and pressure side is possible.

Application:

For pumping neutral or corrosive liquids, uncontaminated or abrasive liquids, liquids containing gases or which tend to froth, and liquids of thigh or low viscosity, including liquids containing fibrous and solid material.

The pump of type G is the main range product of our factory. It can be widely used in many fields.

The pumps of type GS have been developed from the basic range G by a special pump casing. Type denomination " S " means quick cleaning, as the complete pump can be disassmbled with eifortless ease and a biologically impeccable cleaning of each part is possible.

*Food industry:To transfer spirit or wine, waste residue and addition in brewery.

Textile industry:To transfer synthetic fiber liquid viscose liquid.

Paper-making:To transfer black pulp.

Petro-industry : In handling various oil, grease products*Chemical industry:To transfer suspended liquid,emulsion liquid.aid

liquid, soda liquid and salt liquid.

Ship buliding :To transfer residue oil, to be the butter worth pump.

sewage pump and sea water pump ect.

Build industry:To transfer the mortar and plaster.

Nuclear industry:To transfer the radioactive liquid.

Metallurgical and mine:To transfer oxide and waste water. Liquid explosive and drain off water from mine.

Product detail:

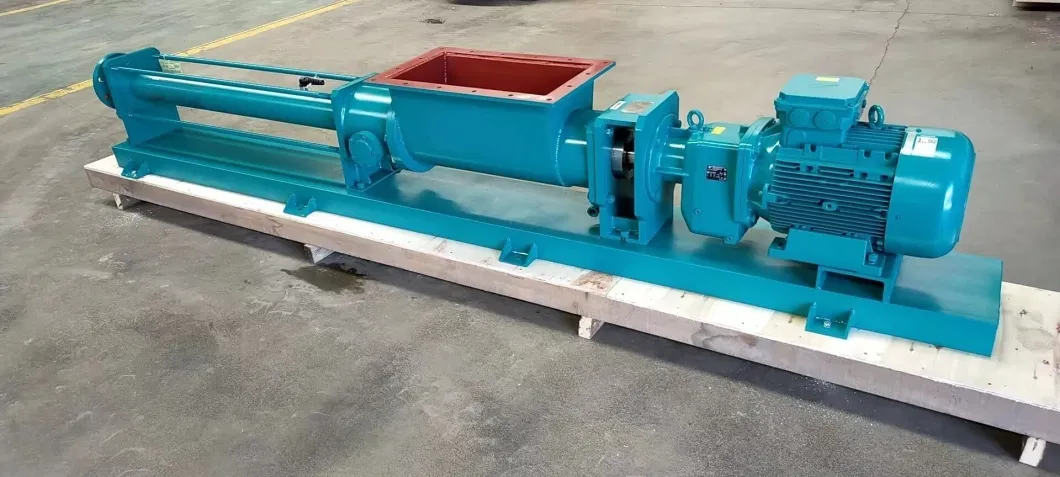

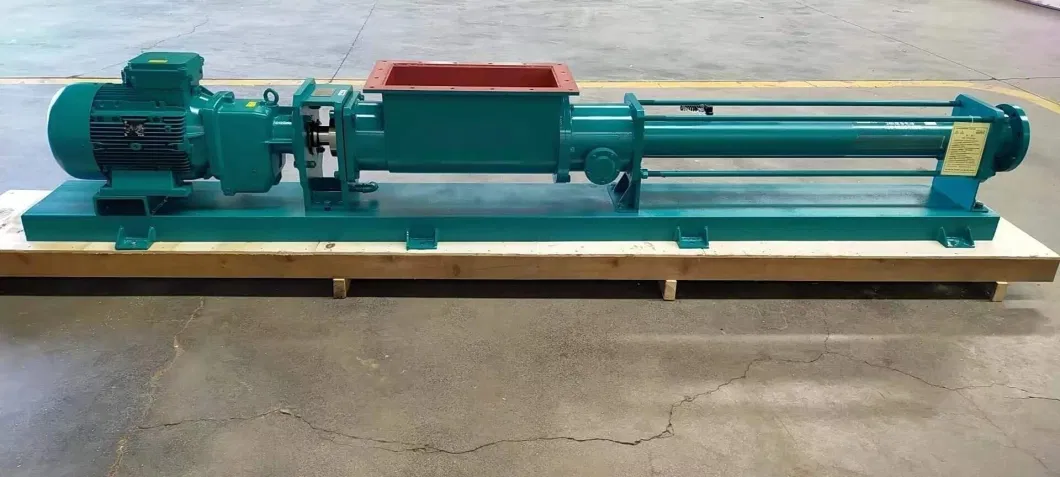

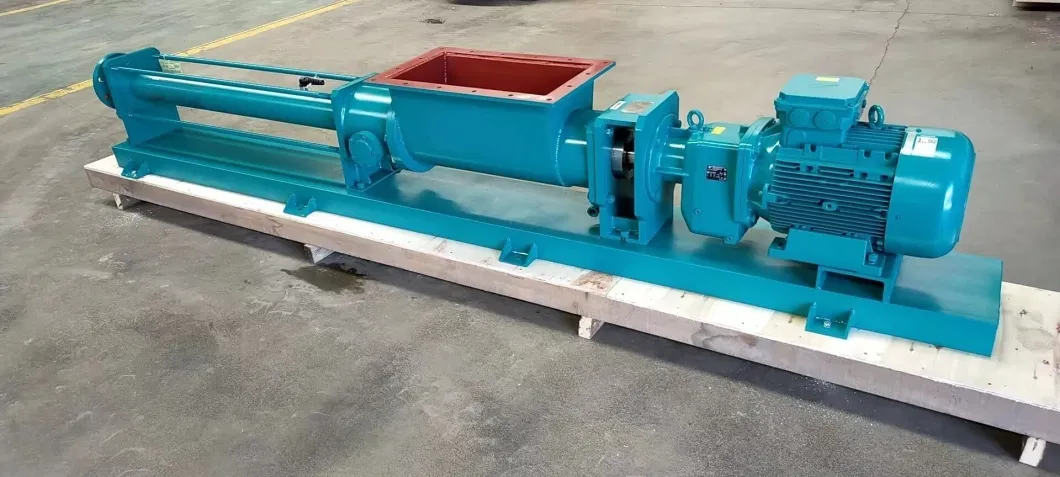

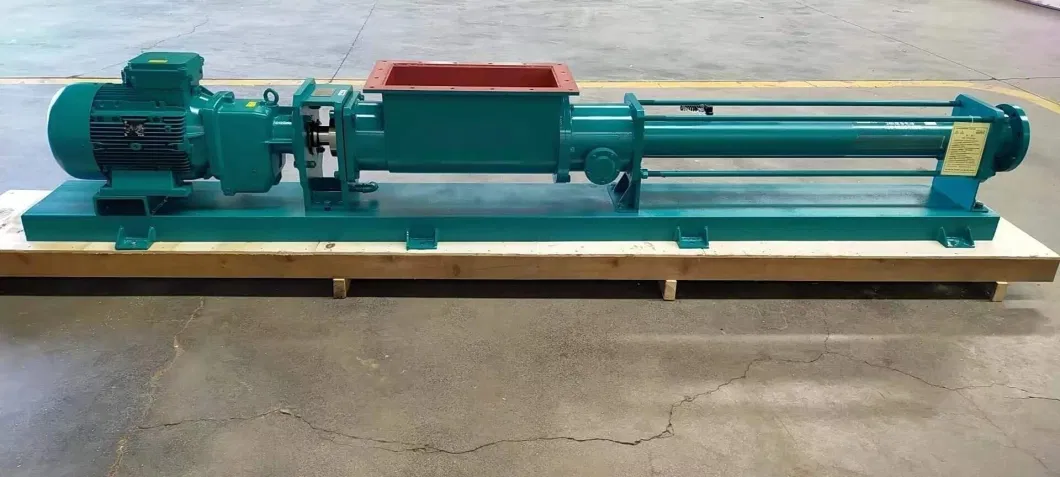

Equipment Display:

Equipment Display:

Packaging & Shipping:

FAQ:

Product Description

Sinlge screw pump features:

The eccentric pump is a screw pump sealed on the inside gearing, belong to rotor displacement pump. The essential part consists of combination of a stator with two-start female thread and a rotor with single-start screw. When the driving shaft causes the rotor in planetary motion by the universal coupling, between the stator and the rotor, being in mesh continually, formed many spaces. As these spaces unchanged in voiume are axial moving, the medium handled is transmited to the outlet port from the inlet port. The liquid transmited to get not confused or disruptive, thus it is the most suitable for liffing mediums containing solid matter. abrasive particles and viscous liquids.

Performance data:

Viscosity: 1.0~ 1500 mm2/s, the viscosity can reach up to 3000000 mm2/s when reduced the speed.

Flow range: 1~ 500 m³/h;

Maximum pressure: 4.0 Mpa;

Max. Temperature: 150ºC

Horizontal Mounting/Vertical mounting

Pump Type | Pressure Range | Capacity Range | Speed range | inlet size | outlet size | Motor Power | |

| (bar) | (m³/h) | (rpm) | (G/DN) | (G/DN) | (kw) | ||

| PN025-2S | 0~12 | 0~0.25 | 0~350 | G1¼ | G1¼ | 0.37 | |

| PN05-1L | 0~6 | 0~0.5 | 0~350 | G1¼ | G1¼ | 0.37 | |

| PN05-2S | 0~12 | 0~0.5 | 0~350 | G1¼ | G1¼ | 0.75 | |

| PN1-1L | 0~6 | 0~1 | 0~350 | G1¼ | G1¼ | 0.75 | |

| PN1-2S | 0~12 | 0~1 | 0~350 | 50 | 50 | 1.5 | |

| PN1-4S | 0~24 | 0~0.5 | 0~250 | 50 | 50 | 3 | |

| PN3-1L | 0~6 | 0~3 | 0~350 | 50 | 50 | 2.2 | |

| PN3-2S | 0~12 | 0~2.5 | 0~350 | 65 | 65 | 3 | |

| PN3-4S | 0~24 | 0~1.5 | 0~250 | 65 | 65 | 5.5 | |

| PN5-1L | 0~6 | 0~5 | 0~320 | 65 | 65 | 3 | |

| PN5-2S | 0~12 | 0~5 | 0~320 | 80 | 80 | 4 | |

| PN5-3S | 0~18 | 0~2 | 0~250 | 80 | 80 | 5.5 | |

| PN5-4S | 0~24 | 0~ 2 | 0~200 | 80 | 80 | 7.5 | |

| PN10-1L | 0~6 | 0~10 | 0~300 | 80 | 80 | 4 | |

| PN10-2S | 0~12 | 0~7 | 0~300 | 80 | 80 | 5.5 | |

| PN10-3S | 0~18 | 0~6 | 0~250 | 80 | 80 | 7.5 | |

| PN10-4S | 0~24 | 0~4 | 0~200 | 80 | 80 | 11 | |

| PN15-1L | 0~6 | 0~15 | 0~300 | 80 | 80 | 5.5 | |

| PN15-2S | 0~12 | 0~12 | 0~300 | 100 | 100 | 7.5 | |

| PN15-3S | 0~18 | 0~10 | 0~250 | 100 | 100 | 11 | |

| PN15-4S | 0~24 | 0~7 | 0~200 | 100 | 100 | 15 | |

| PN25-1L | 0~6 | 0~25 | 0~280 | 100 | 100 | 7.5 | |

| PN25-2S | 0~12 | 0~22 | 0~300 | 125 | 125 | 11 | |

| PN25-3S | 0~18 | 0~15 | 0~250 | 125 | 125 | 15 | |

| PN25-4S | 0~24 | 0~12 | 0~200 | 125 | 125 | 18.5 | |

| PN50-1L | 0~6 | 0~50 | 0~280 | 125 | 125 | 11 | |

| PN50-2S | 0~12 | 0~35 | 0~250 | 150 | 150 | 22 | |

| PN50-3S | 0~18 | 0~30 | 0~230 | 150 | 150 | 30 | |

| PN50-4S | 0~24 | 0~26 | 0~200 | 150 | 150 | 37 | |

| PN80-1L | 0~6 | 0~80 | 0~280 | 150 | 150 | 22 | |

| PN80-2S | 0~12 | 0~60 | 0~280 | 150 | 150 | 37 | |

| PN80-3S | 0~18 | 0~42 | 0~200 | 150 | 150 | 45 | |

| PN80-4S | 0~24 | 0~25 | 0~150 | 150 | 150 | 55 | |

| PN120-1L | 0~6 | 0~120 | 0~250 | 150 | 150 | 37 | |

| PN120-2S | - 2 | 0~100 | 0~270 | 200 | 200 | 45 | |

| PN120-3S | 0~18 | 0~60 | 0~180 | 200 | 200 | 55 | |

| PN120-4S | 0~24 | 0~50 | 0~150 | 200 | 200 | 55 | |

| PN180-1L | 0~6 | 0~180 | 0~220 | 200 | 200 | 45 | |

| PN1 80 2s | 0~12 | 0~170 | 0~220 | 200 | 200 | 55 | |

| PN300-1L | 0~6 | 0~300 | 0~220 | 200 | 200 | 55 | |

Features:

The coupling rod terminates at both ends in pin type universal joints,The pin and bushing are made of special metal, the durability of the joint is improved greatly. Simple construction. easy and quick to dismantle(Fig.l). Stator provided at both ends with external collars vulcanized to it, which provide a safe seal to the suction and discharge section. It protect the stator casing against corrosion. Between the suction casing and bearing housing is stiuated an inter changeable housing for a suiffing box or mechanical seal(pumps can be converted retrospectively to a different type of seal). PN pump's suction-, discharge-connections with threaded connection:according to DIN 1187-A as a standard. Thus, a quick disassembly of pipe and hose connections on suction and pressure side is possible.

Application:

For pumping neutral or corrosive liquids, uncontaminated or abrasive liquids, liquids containing gases or which tend to froth, and liquids of thigh or low viscosity, including liquids containing fibrous and solid material.

The pump of type G is the main range product of our factory. It can be widely used in many fields.

The pumps of type GS have been developed from the basic range G by a special pump casing. Type denomination " S " means quick cleaning, as the complete pump can be disassmbled with eifortless ease and a biologically impeccable cleaning of each part is possible.

*Food industry:To transfer spirit or wine, waste residue and addition in brewery.

Textile industry:To transfer synthetic fiber liquid viscose liquid.

Paper-making:To transfer black pulp.

Petro-industry : In handling various oil, grease products*Chemical industry:To transfer suspended liquid,emulsion liquid.aid

liquid, soda liquid and salt liquid.

Ship buliding :To transfer residue oil, to be the butter worth pump.

sewage pump and sea water pump ect.

Build industry:To transfer the mortar and plaster.

Nuclear industry:To transfer the radioactive liquid.

Metallurgical and mine:To transfer oxide and waste water. Liquid explosive and drain off water from mine.

Product detail:

Packaging & Shipping:

FAQ: