- Overview

- Product Description

- Company Profile

- Packaging & Shipping

- FAQ

Basic Info.

Product Description

| Size | Customized |

| Place of Origin | China Hebei |

| Working Temperature | -50ºC~250ºC |

| Material | PTFE |

| Application | Pharmaceuticals Liquid Chromatography Food Processing Space Exploration Tire Production Hydraulics Vacuum Service Oilfield Exploration and Production etc |

| Package | plastic film bag and carton |

| Model Number | customized |

| Color | White, Blue, Brown, Black, Grey |

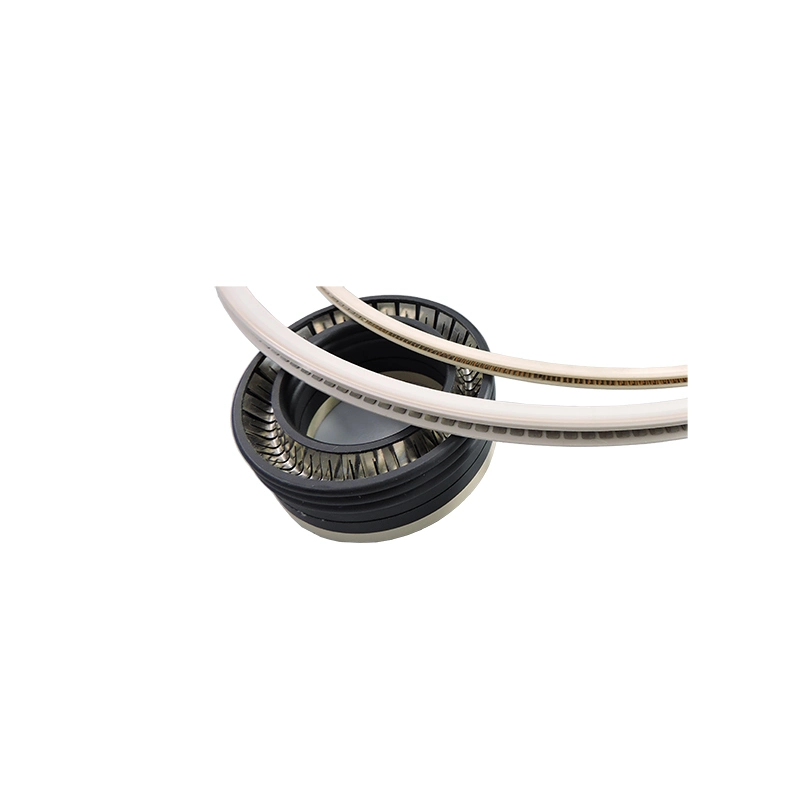

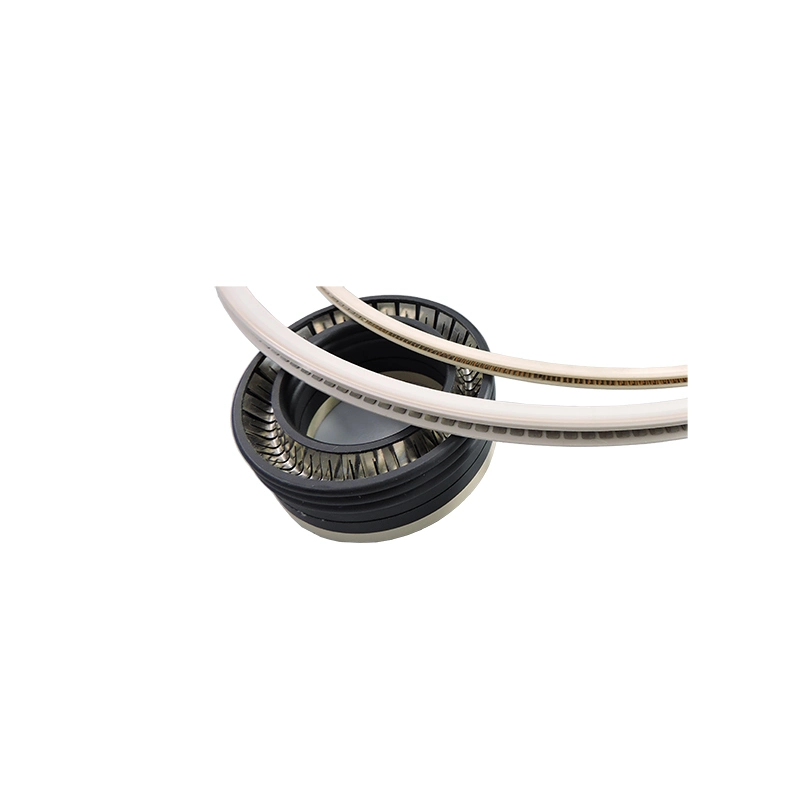

spring energized oil seal

Spring energized seals design is based on three principles:

High-performance, engineered materials

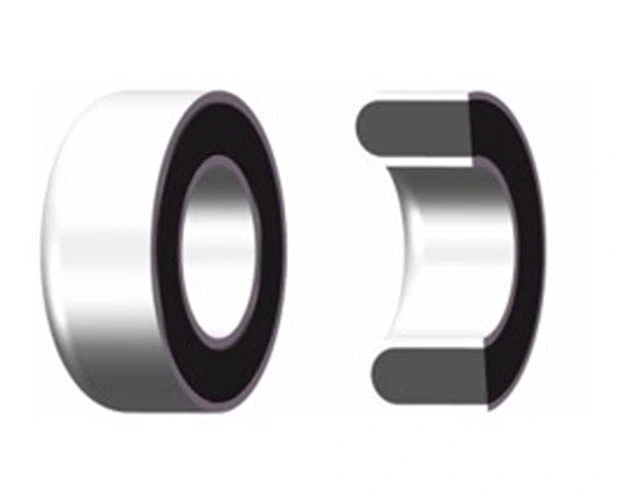

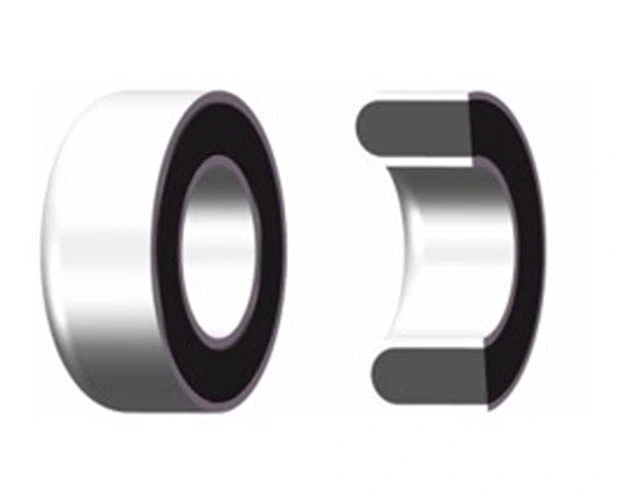

U-cup style seal jackets

Metal spring energizers

MATERIALS

SAIXUAN combines material technology and seal design to optimize your sealing performance. The material technology uses high performance engineered polymers made from PTFE, PEEK, Polyimides,other polymer materials specified for your application.

SPRING ENERGIZED SEAL FEATURES

Temperature: -268°C (-450°F) to +316°C (+600°F)

Pressure: Vacuum up to 3448 bar (50,000 psi)

Low and controlled friction

Broad chemical resistance

Spring-energized seals made of PTFE are characterized by:

- Low and high temperature resistance (-328°F to 500°F, -200°C to 260°C)

- FDA compliant compounds and designs available

- Exceptional resistance to chemicals and corrosion

- Provide the lowest coefficient of friction of all sealing materials

- Unlubricated dry-running capabilities

- Pressure for standard designs up to 3,000psi (210 bar)

- High pressure special seal designs up to 20,000psi (1380bar)*

Good service --- worth your trust

Factory direct sale ----Customized service for you

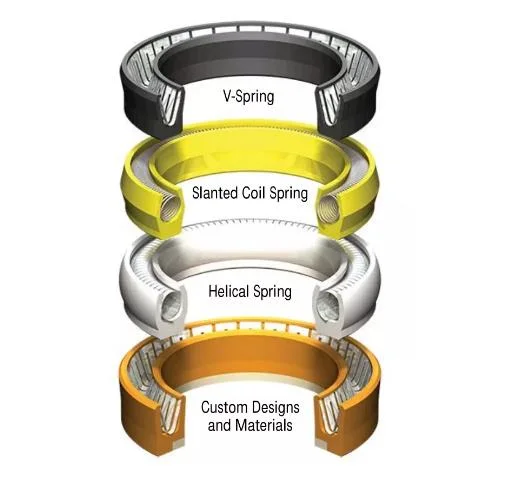

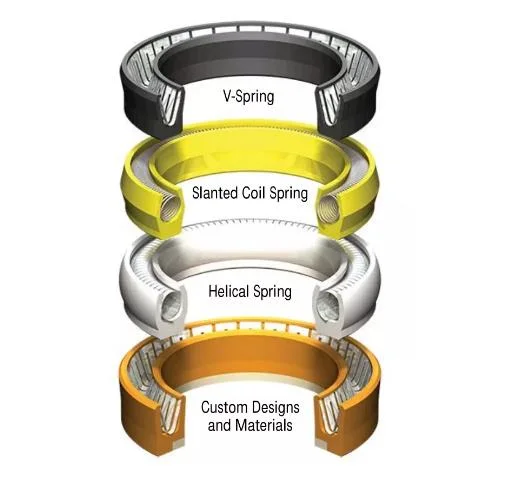

The different shape of spring seal/ spring energized seal

1.V-spring seals are designed for used in high or low presseure dynamic reciprocationg or rotary applications.

2.Slanted Coil Spring Seals are for low friction, dynamic reciprocating and rotary applications. The seal produces a near flat load curve when compressed ( installed ). They provide constant predictable loads through their very wide deflection range.

3.Helical Spring seals are designed for used in static or slow, infrequent dynamic sealing application due to high compression load over a small deflection range, which make these seals suitable when low pressure or vacuum and very low temperature ( cryogenic ) are present.

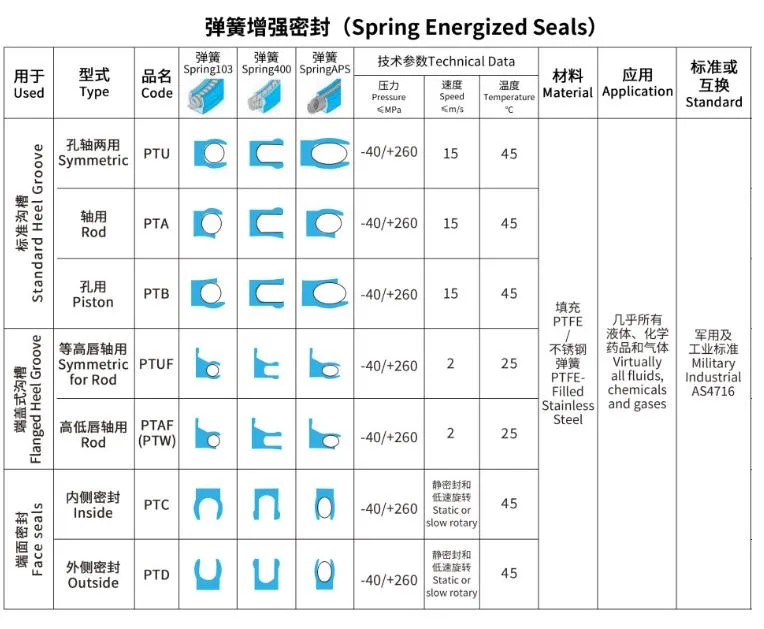

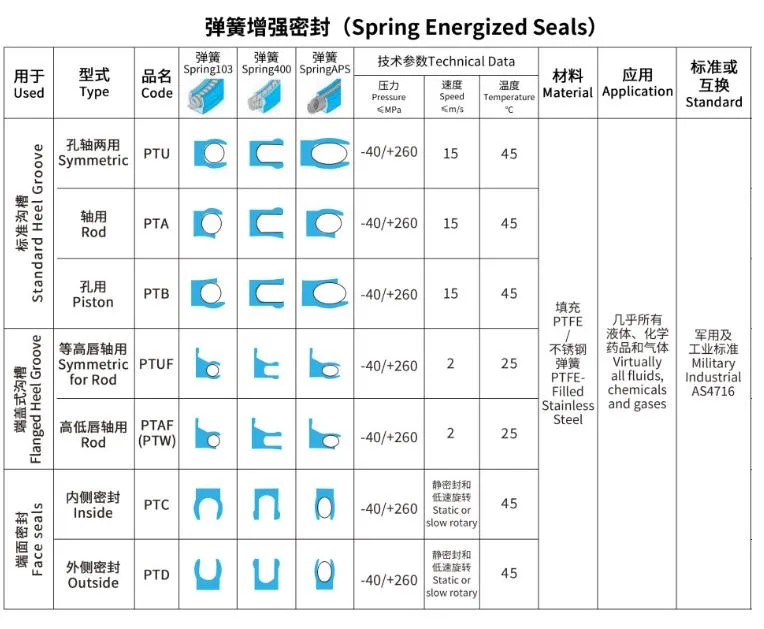

Energized PTFE Spring Seals:

| Type | Use for | Technical | Application | Material |

| Symmetric | standard heel groove | temperacture:-40~+260 °C ,speed ≤m/s:15,pressure≤ Mpa:45 | virtually all fluids,chemicals and gases | PTFE-filled stainless steel |

| rod | standard heel groove | temperacture:-40~+260 °C ,speed ≤m/s:15,pressure≤ Mpa:45 | virtually all fluids,chemicals and gases | PTFE-filled stainless steel |

| piston | standard heel groove | temperacture:-40~+260 °C ,speed ≤m/s:15,pressure≤ Mpa:45 | virtually all fluids,chemicals and gases | PTFE-filled stainless steel |

| symetric for rod | flanged heel groove | temperacture:-40~+260 °C ,speed ≤m/s:2,pressure≤ Mpa:25 | virtually all fluids,chemicals and gases | PTFE-filled stainless steel |

| high-low lip rod | flanged heel groove | temperacture:-40~+260 °C ,speed ≤m/s:2,pressure≤ Mpa:25 | virtually all fluids,chemicals and gases | PTFE-filled stainless steel |

| inside | face seal | temperacture:-40~+260 °C ,speed:static or slow rotary,pressure≤ Mpa:45 | virtually all fluids,chemicals and gases | PTFE-filled stainless steel |

| outside | face seal | temperacture:-40~+260 °C ,speed:static or slow rotary,pressure≤ Mpa:45 | virtually all fluids,chemicals and gases | PTFE-filled stainless steel |

Applications & Industries

Spring-energized PTFE Seals are suitable for service in the following industries:

- Pharmaceuticals

- Liquid Chromatography

- Food Processing

- Space Exploration

- Tire Production

- Hydraulics

- Vacuum Service

- Oilfield Exploration and Production

- Paint and Solvents

- Steel Mills

- Adhesives

- Cryogenic Service

- Liquid Handling Swivels

- Pumps and Valves

- Gas Production and Transportation

- Semiconductors

- Medical Equipment

- Gas Handling Equipment

Valve stem packing for wellhead equipment in PEEKcustomized Material:PTFE/PEEKStyle:Mechanical Seal Compound:PEEK/PTFE/UHMWPE/PCTFE Application:Hydraulic Temperature:-50ºC~250ºCPressure:≤60MpaStandard or Nonstandard: standard Sealing PrincipleSPRING ENERGIZED PTFE SEAL APPLICATIONSOilfield Equipment,Compressors,Mechanical Seals Cryo Coolers,Hydraulic Actuators,Chemical Pumps Aircraft Engines,Brake Systems,Food Processing Equipmen

Direction for use

This Vee packing set ,U-packing PTFE+FKM/FPM/NBR/HNBR Filled and the Spring loaded Filled PTFE Stem Packing are Used for Cameron FC gate valves and FL gate valves

Size Chart of V packing set U-packing and stem packing gate valve seals

Name Size U-packing 1-3/4 x 1 U-Packing;2-3/8 x 1-5/8 U-Packing,

3-1/2 x 2-3/4 U-Packing;

2 x 1-1/4 U-Packing;

2-3/4 x 2 U-Packing;

2 x 3.125 x 1.13;

2-1/4 x 1-1/2 U-Packing;

3 x 2 U-Packing;

2.75x3.50x0.815Vee packing set /Stem packing set 1/2*2-1/4; 2-3/4*2

3-1/2*2-3/4

Q1. Are you a factory or trading company?

We have factory in Xingtai and office in Shijiazhuang, Hebei Province. Convenient Transportation. It's not far from the Zhengding international airport. We warmly welcome clients from all over the world to come to our factory for visit and cooperation.

Q2. What's your sample policy ?

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q3. Can you produce according to the samples or drawings?

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q4. What's your Delivery time ?

If the good are in stock generally it is 3-5 working days after receiving your advance payment.

About 7-15 working days if we have mold or 21-28 working days without mold.

The specific delivery time depends on the items and quantity of your order quantity.

Q5.What's your payment terms?

For sample and small order, 100% Paypal. Western Union, T/T.

For bulk order, T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q6. Why choose to cooperate with you? What's your advantage?

1). Strong point:We have our own factory,so the price can be competitive and the quality is reliable.

2). We can offer you a good after-sell service, prompt deliver.

3). We can provide various size and colors according to customers' requirements.

4). By long time testing, quality proved to be excellent.

5). Updated product design.

6). Advanced manufacturing process, with global standards.

7). We win by the high quality and then have a long-term business relationship.

Q7. How do you make our business long-term and good relationship?

1). We keep good quality and competitive price to ensure our customers benefit;

2). We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Our rubber seals are diverse and extensive, so if there is no item what you need, we encourage you to send the drawing or samples to us directly for more information.