- Overview

- Product Description

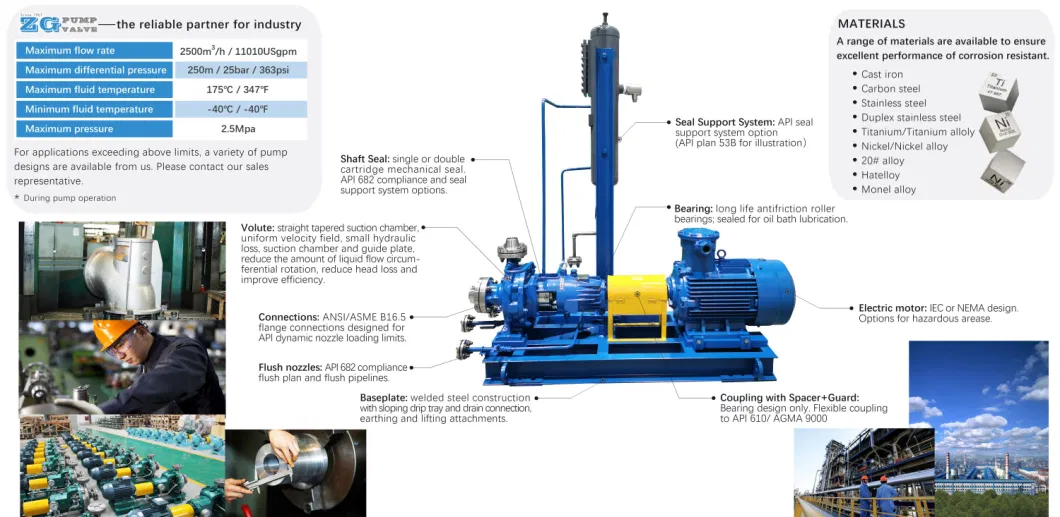

- Product Parameters

- Pump structure

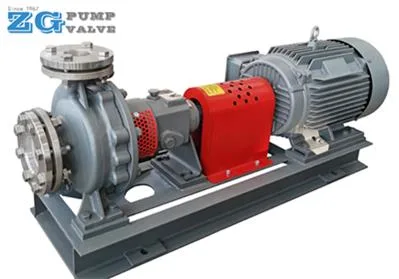

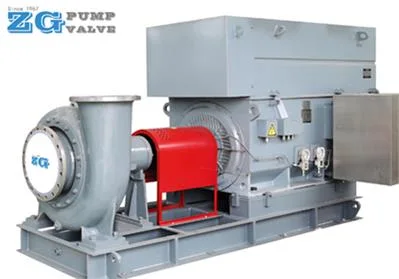

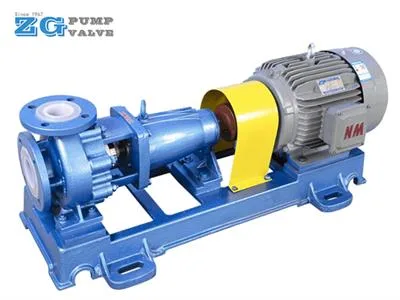

- Detailed Photos

- Pump features

- Company Profile

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Brief introduction of Chemical Centrifugal Pumps:

The Chemical Process Pump is a centrifugal pump of horizontal, single stage, single suction, volute casing type, cantilever design, its performance parameters conform to ISO2858 and its technical requirement conform to ISO5199. The chemical centrifugal pumps with closed impeller is designed to transfer clean or medium containing a small number of particles, easy to crystallize, easy to precipitate working conditions. The chemical centrifugal pumps with open impeller is designed to transfer the pulp below 8% density, fibers less than 50mm and other liquid with the solid content below 30%. Large channel open impeller pumps have a strong capacity to convey fiber, particles or pulp.

Pumps are subjected to the most extreme stresses: acids, alkalis, high temperatures and abrasive fluids. To guarantee its customers reliable products, we always focus on materials. Select material of Stainless Steel (SS304, SS316, SS316L, 904L), Duplex Stainless Steel (CD4MCu, 2205, 2507), Titanium, Nickel, Monel ,Hastelloy, 20# alloy…chemical centrifugal pumps could meet the requirements of high temperature, high pressure, harsh working conditions of corrosion or abrasion. Chemical centrifugal process pumps are widely used in chemical, caustic soda, chlor-alkali, salt, pulp, nitric, petrochemical industries.

Applications of Chemical Centrifugal Pumps:

- Chemical and process industry

- Soda, caustic soda, soda ash, chlor-alkali

- High-concentration nitric and chromic acid

- Sulphuric and phosphoric acid

- Salt extraction and brine processing

- Petrochemical industry, Refinery

- Coking plants

- Textile and pulp, paper, board industries

- Food and sugar-making industries

- Aluminium oxide industry / Solids transport

- Steel and metal-working industries

- Mining industry / Coal mining and extraction

- Flue gas desulphurisation of thermal power plant

- Limestone and milk of lime suspensions

- Acidic chloride-containing scrubber suspensions

- Acidic process water

- Waste water treatment plants

- Offshore and marine engineering

Performance range of Chemical Centrifugal Pumps:

Parameters of Chemical Centrifugal Pumps:

| Flow rate: | Q= 0.8~2500 (m³/h) |

| Total head: | H=4~250 (m) |

| Pump speed: | n=1450/2900rpm |

| Fluid s.g.: | γ≤1.85 |

| Fluid temperature: | T=-20~175ºC |

| Pump diameter: | Ф50~450mm |

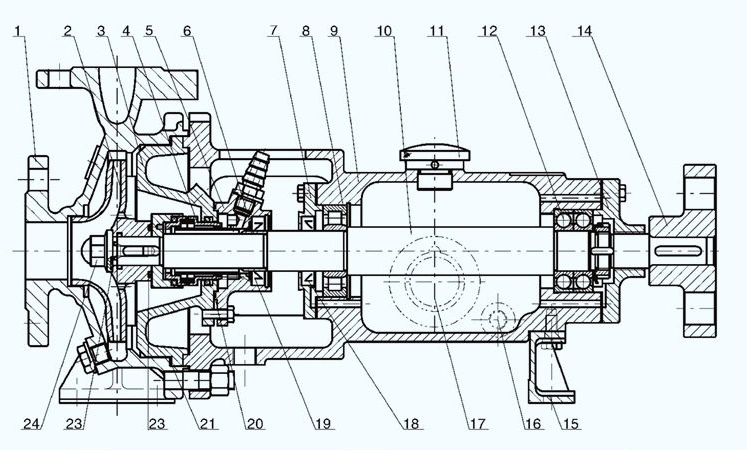

Structure of the Chemical Centrifugal Pump: 1 PUMP CASING adopts precision casting, number milling processing and fine grinding to ensure that the pump casing profile is accurate, the material is dense and uniform, and the hydraulic performance is excellent.

1 PUMP CASING adopts precision casting, number milling processing and fine grinding to ensure that the pump casing profile is accurate, the material is dense and uniform, and the hydraulic performance is excellent.

2 IMPELLER NUT self-locking impeller nuts eliminate the risk of loose.

3 IMPELLER optimized design of impeller, wider range of high efficiency and application range.

4 PUMP COVER back pull-out design to facilitate quick access for servicing.

5 MECHANICAL SEAL different mechanical seals according to different working conditions.

6 FRONT BEARING GLAND

7 SHAFT thickened heavy-duty shaft, provides maximum strength and stiffness for harsh working conditions, providing bearing capacity and operational stability.

8 BEARING HOUSING reliable, heavy-duty bearing unit helps extend bearing's lifecycle, reduces unexpected shutdowns and maintenance costs.

9 AIR VENT COVER

10 BRACKET

11 BACK BEARING GLAN

| 1 Pump casing | 9 Bearing housing | 17 Oil-analysis standard |

| 2 Impeller | 10 Shaft | 18 Skeleton oil seal |

| 3 Pump cover | 11 Air vent cover | 19 Skeleton oil seal |

| 4 Mechanical seal | 12 Back bearing | 20 O ring of seal end gland |

| 5 Seal end gland | 13 Back bearing gland | 21 Pump cover washer/O ring |

| 6 Wear sleeve | 14 Pump coupling | 22 O ring of impeller |

| 7 Front bearing gland | 15 Bracket | 23 O ring of impeller nut |

| 8 Front bearing | 16 Pipe plug | 24 Impeller nut |

The chemical centrifugal pump, the optimized hydraulic design delivers superior performance through high efficiency impellers and volutes casings, contributing to low energy consumption subsequent total cost of ownership. Thanks to our casting and materials expertise, our customers can be confident that our pumps will withstand even the most demanding operating conditions. With thousands of installations all over the world, products and services of Zigong Pump & Valve have stood the test of time. Drawing on over 70 years of experience as a manufacturer of pumps, we at Zigong Pump & Valve meet the continuously rising demands our customers place on high-performance products.

The chemical centrifugal pump, the optimized hydraulic design delivers superior performance through high efficiency impellers and volutes casings, contributing to low energy consumption subsequent total cost of ownership. Thanks to our casting and materials expertise, our customers can be confident that our pumps will withstand even the most demanding operating conditions. With thousands of installations all over the world, products and services of Zigong Pump & Valve have stood the test of time. Drawing on over 70 years of experience as a manufacturer of pumps, we at Zigong Pump & Valve meet the continuously rising demands our customers place on high-performance products.

The Features of Chemical Centrifugal Pumps:

- Conform to ISO2858(GB5662)and GB/T5656(equivalent to ISO5199)

- Heavy shaft of increased diameter, the bearing capacity of bearings is averagely increased by 75~160%, the life of bearings are tremendously extended.

- Forced internal cooling cartridge mechanical seal and big sealing chamber reduced the possibility of breakdown.

- Easy adjust method of pump rotor part to maintain low pressure of sealing chamber, to reduce the axial force,and therefore guaranteed the stable operation of pump.

- Several transforming designs enlarged the range of application of pump, increased the reliability of pumping special fluids.

- High interchangeability of pump parts reduced the cost on spares parts for clients.

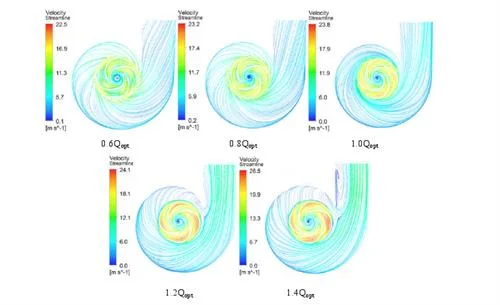

Based on CFD technology, Optimize pump hydraulic performance more efficiently.

Chemical centrifugal process pumps, the optimised hydraulic design delivers superior performance through high efficiency impellers and volutes casings, contributing to low energy consumption subsequent total cost of ownership. Adopting the optimization algorithm provided by Isight, it integrates the functional optimization platform of 3D modeling software Catia, grid division software ICEM and numerical simulation software CFX.

Pump Configuration:

We have eight modernized workshops covering 12,000 square meters, which producing ability was designed as 18000 pieces per year. The factory consists of foundry workshop, finish-machining workshop, plate welding workshop, assembly workshop and testing center. The maximum lifting ability for tramelling crane is 50 metric tons; There are 510 sets of large and essential processing facilities which enable the requirements for producing all kinds of industrial pumps. Casting of parts and components is an important part of the industrial pump production process. The precise control of the pump material smelting and the flow path size of the over-current components is our key control program for the quality of the pump products. The annual production capacity of 8,000 tons of alloy cast iron and dozens of new casting equipment such as AOD refining furnace and spectrum analyzer, as well as a group of skilled stylists, ensure the excellent quality of our castings.

Casting of parts and components is an important part of the industrial pump production process. The precise control of the pump material smelting and the flow path size of the over-current components is our key control program for the quality of the pump products. The annual production capacity of 8,000 tons of alloy cast iron and dozens of new casting equipment such as AOD refining furnace and spectrum analyzer, as well as a group of skilled stylists, ensure the excellent quality of our castings.

HOT SELLING PUMPS

CERTIFICATES & PATENTS TESTING

TESTING

The comprehensive pump testing center. Make sure the quality control can be refined in the material inspection,components check,performance test.

Product is packaged according to the customer's needs. Plywood boes are used according to international regulations.

Why choose us?

5 DECADES

Established in 1967, long history of pump making brings us rich experience, making us a professional pump manufaturer and ranking us as a famous pump factory in China.

500+ STAFFS

Well trained and professional engineers and workers guarantees the in time delivery and offers professional pump solutions to our clients.

96700m2 WORKSHOPS

Large and modernized workshops and facilities enables the efficient and strict QA&QC procedures and therefore assures the qualified products.

20+ BRANCHES

Established 20+ branches offices and subsidiaries throughout China, they offer closer and in time services to our clients. And our overseas customers are from different places of the world.

3000+ CLIENTS

Own more than 3000 clients both in China and overseas, which is an approval of our product quality and a praise of our service.

20+ PATENTS

Gained more than 20 patents, which is a strong proof of the ability of R&D and a backup of product quality.

Q: How long is your factory history?

A: Our factory was established in 1967.

Q: How many staffs does your factory have?

A: We have around 500 staffs.

Q: What international certificates does your factory have?

A: We have API, CE, ISO9001...

Q: Does your factory have foundry for yourself?

A: We have our own two foundries in our factory.

Q: What after sales service your factory can provide?

A: Generally, most of the issues can be solved by free guidance of video calls. But paid site service is also available.

Q: What is your product warranty?

A: 12 months since commissioning or 18 months after shipment,whichever is earlier.

Q: What is your factory's annual output capacity?

A: Around 20,000 pcs of various type of pumps.