Basic Info.

Model NO.

MIH

Impeller

Closed

Usage

Pump

Theory

Centrifugal Pump

Structure

Single-Stage Pump

Power

Electric

Material

Cr27, Cr15mo3

Wet End

A05, A07, A49, Rubber, Polyurethane

Bearing

NSK, SKF, Timken

Sealing

Mechanical Seal, PTFE Packing, Hi-Seal

Lubrication

Grease and Oil

Color

Customer Specifications Upon Request

Standard or Nonstandard

Standard

Transport Package

Wooden Case

Specification

SGS, ISO

Trademark

Modo

Origin

Hebei China

HS Code

8413810090

Production Capacity

8, 000 Sets/Year

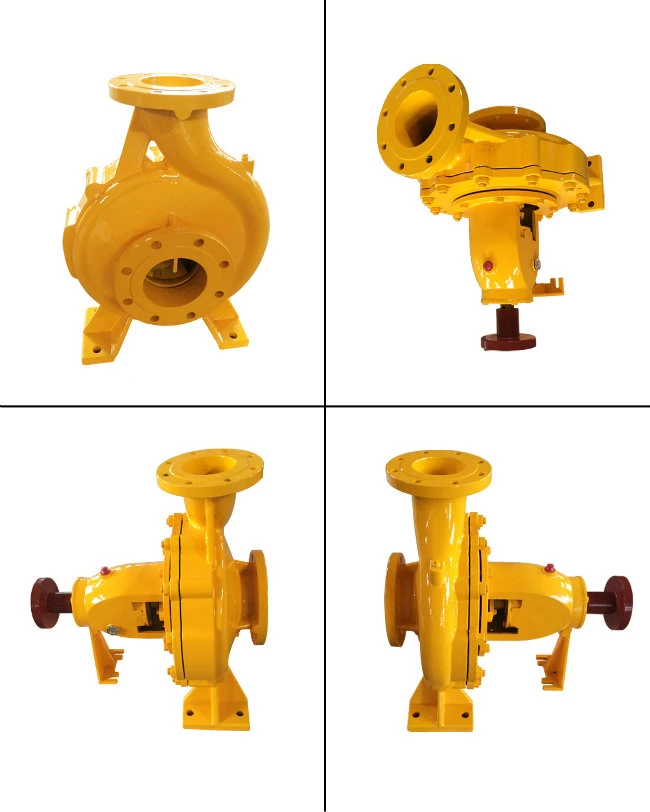

Product Description

Stainless steel pump for sulphuric acid

Characteristics

Description

Liquid handling requirements are much more involved than they were years ago. The variety of liquids being handled has increased along with temperatures and pressures. Today's installations demand quiet, smooth running pumps with long life. The reliable 1600 pumps offer an economical solution to your liquid handling problems.

Features

Choice of piston ring style labyrinth

Fully interchangeable with the common brand reducing inventory hold requirements

A full range of mechanical seal adaptations available upon request

Oil lubrications or packed grease

Painted to customer specifications upon request

Application

Domestic water boosters

Sprinkler/Firefighting

Water treatment plants

Seawater pumping

Chemical / Processing

Food processing

Irrigation

Designed for heavy duty industrial use including belt drive applications.

General water transfer in processing plants, mines, construction sites and irrigation

Details

FAQ

A: What kind of company you are?

Q: We are centrifugal pump manufacture located in Boy Town, Baoding, China, with more than 20years experiences. We were gaining good reputation among our customers for our professional, warm and thoughtful service. Because we know that a long terms business based on the quality control, price, packing, delivery time etc.

A: What's the quality assurance you provided and how do you control quality?

Q: Established a procedure to check products at all stages of the manufacturing process: Casting, Heat treatment, Machining, Assembly, and Testing.

Q: Can you install the motor or diesel engine with the pump for us?

A: yes, we can, it's no problem, and we are experienced in this.

Q: What's your MOQ?

A: Trial sample order is OK.

Q: What are your payment terms?

A: T/T, L/C, D/P, D/A......

Q: What certificates do you have?

A: CE, ISO 2008, UL.....

Q: How about the warranty?

A: One year warranty for pumps, it depends on other pump working condition details.

Q: What is the delivery time?

A: 15-30 days according to customer quantities.

Q: Can you do OEM brand?

A: Yes, Welcome.

Q: What information should I offer to get pump solution?

1, Material:

2, Head: m

3, Flow: m3/h

4, Medium size: mm

5, Particle shape (smooth or sharp):

6, Medium pH level:

7, Temperature:

8, Drive type:

9. Power supply:

Contact me for detail offer with curve and drawing!

Characteristics

| ·Type: | ·Media: | ·Application: |

| centrifugal | Multi-fluid | handing |

| ·Other characteristics: | ·Flow rate: | ·Head |

| Single-stage | Min.:0m3/h | Min: 0m |

| Max.: 954m3/h | Max: 158m |

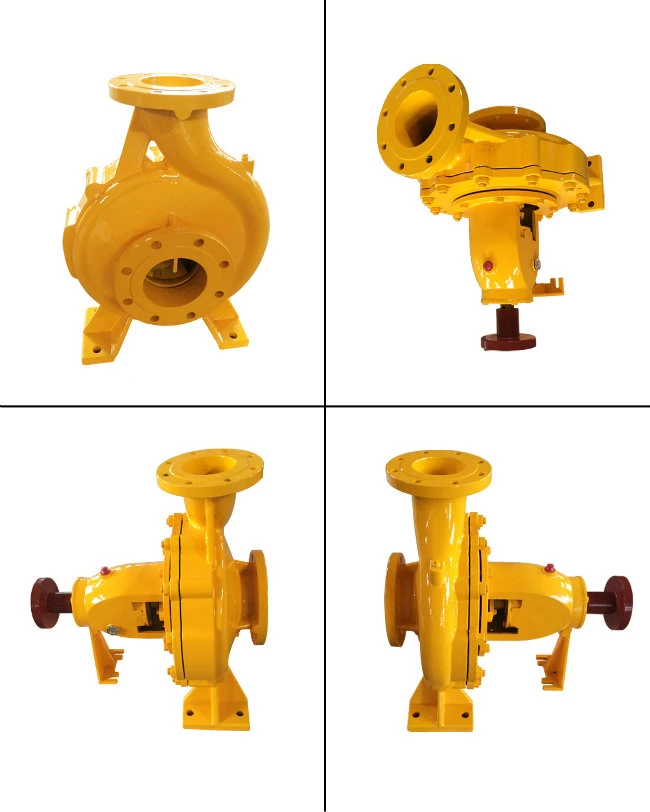

Description

Liquid handling requirements are much more involved than they were years ago. The variety of liquids being handled has increased along with temperatures and pressures. Today's installations demand quiet, smooth running pumps with long life. The reliable 1600 pumps offer an economical solution to your liquid handling problems.

Features

Choice of piston ring style labyrinth

Fully interchangeable with the common brand reducing inventory hold requirements

A full range of mechanical seal adaptations available upon request

Oil lubrications or packed grease

Painted to customer specifications upon request

| Model | Flow | Lift head | Rotation speed | Motor power | Diameter(mm) | Diameter(mm) |

| (m3/h) | (m) | (r/min) | (kw) | Suction | Outlet | |

| IS50-32-125 | 12.5 | 20 | 2900 | 2.2 | 50 | 32 |

| 6.3 | 5 | 1450 | 0.55 | 50 | 32 | |

| IS50-32-160 | 12.5 | 32 | 2900 | 3 | 50 | |

| 6.3 | 8 | 1450 | 0.55 | 50 | 32 | |

| IS50-32-200 | 12.5 | 50 | 2900 | 5.5 | 50 | 32 |

| 6.3 | 12.5 | 1450 | 0.75 | 50 | 32 | |

| IS50-32-250 | 12.5 | 80 | 2900 | 11 | 50 | 32 |

| 6.3 | 20 | 1450 | 1.5 | 50 | 32 | |

| IS65-50-125 | 25 | 20 | 2900 | 3 | 65 | 50 |

| 12.5 | 5 | 1450 | 0.55 | 65 | 50 | |

| IS65-50-160 | 25 | 32 | 2900 | 5.5 | 65 | 50 |

| 12.5 | 8 | 1450 | 0.75 | 65 | 50 | |

| IS65-40-200 | 25 | 50 | 2900 | 7.5 | 65 | 40 |

| 12.5 | 12.5 | 1450 | 1.1 | 65 | 40 | |

| IS65-40-250 | 25 | 80 | 2900 | 15 | 65 | 40 |

| 12.5 | 20 | 1450 | 2.2 | 65 | 40 | |

| IS65-40-315 | 25 | 125 | 2900 | 30 | 65 | 40 |

| 12.5 | 32 | 1450 | 4 | 65 | 40 | |

| IS80-65-125 | 50 | 20 | 2900 | 5.5 | 80 | 65 |

| 25 | 5 | 1450 | 0.75 | 65 | ||

| IS80-65-160 | 50 | 32 | 2900 | 7.5 | 80 | 65 |

| 25 | 8 | 1450 | 1.5 | 80 | 65 | |

| IS80-50-200 | 50 | 50 | 2900 | 15 | 80 | 50 |

| 25 | 12.5 | 1450 | 2.2 | 80 | 50 | |

| IS80-50-250 | 50 | 80 | 2900 | 22 | 80 | 50 |

| 25 | 20 | 1450 | 3 | 80 | 50 | |

| IS80-50-315 | 50 | 125 | 2900 | 37 | 80 | 50 |

| 25 | 32 | 1450 | 5.5 | 80 | 50 | |

| IS100-80-125 | 100 | 20 | 2900 | 11 | 100 | 80 |

| 50 | 5 | 1450 | 1.5 | 100 | 80 | |

| IS100-80-160 | 100 | 32 | 2900 | 15 | 100 | 80 |

| 50 | 8 | 1450 | 2.2 | 100 | 80 | |

| IS100-65-200 | 100 | 50 | 2900 | 22 | 100 | 65 |

| 50 | 12.5 | 1450 | 4 | 100 | 65 | |

| IS100-65-250 | 100 | 80 | 2900 | 37 | 100 | 65 |

| 50 | 20 | 1450 | 5.5 | 100 | 65 | |

| IS100-65-315 | 100 | 125 | 2900 | 75 | 100 | 65 |

| 50 | 32 | 1450 | 11 | 100 | 65 | |

| IS125-100-200 | 200 | 50 | 45 | 125 | 100 | |

| 100 | 12.5 | 1450 | 7.5 | 125 | 100 | |

| IS125-100-250 | 200 | 80 | 2900 | 75 | 125 | 100 |

| 100 | 20 | 1450 | 10 | 100 | ||

| IS125-100-315 | 200 | 125 | 2900 | 110 | 125 | 100 |

| 100 | 32 | 1450 | 15 | 125 | 100 | |

| IS125-100-400 | 100 | 50 | 1450 | 30 | 125 | 100 |

| IS150-125-250 | 200 | 20 | 1450 | 18.5 | 150 | 125 |

| IS150-125-315 | 200 | 32 | 1450 | 30 | 150 | 125 |

| IS150-125-400 | 200 | 50 | 1450 | 45 | 150 | 125 |

| IS200-150-250 | 400 | 20 | 1450 | 37 | 200 | 150 |

| IS200-150-315 | 400 | 32 | 1450 | 55 | 200 | 150 |

| IS200-150-400 | 400 | 50 | 1450 | 90 | 200 | 150 |

Application

Domestic water boosters

Sprinkler/Firefighting

Water treatment plants

Seawater pumping

Chemical / Processing

Food processing

Irrigation

Designed for heavy duty industrial use including belt drive applications.

General water transfer in processing plants, mines, construction sites and irrigation

Details

FAQ

A: What kind of company you are?

Q: We are centrifugal pump manufacture located in Boy Town, Baoding, China, with more than 20years experiences. We were gaining good reputation among our customers for our professional, warm and thoughtful service. Because we know that a long terms business based on the quality control, price, packing, delivery time etc.

A: What's the quality assurance you provided and how do you control quality?

Q: Established a procedure to check products at all stages of the manufacturing process: Casting, Heat treatment, Machining, Assembly, and Testing.

Q: Can you install the motor or diesel engine with the pump for us?

A: yes, we can, it's no problem, and we are experienced in this.

Q: What's your MOQ?

A: Trial sample order is OK.

Q: What are your payment terms?

A: T/T, L/C, D/P, D/A......

Q: What certificates do you have?

A: CE, ISO 2008, UL.....

Q: How about the warranty?

A: One year warranty for pumps, it depends on other pump working condition details.

Q: What is the delivery time?

A: 15-30 days according to customer quantities.

Q: Can you do OEM brand?

A: Yes, Welcome.

Q: What information should I offer to get pump solution?

1, Material:

2, Head: m

3, Flow: m3/h

4, Medium size: mm

5, Particle shape (smooth or sharp):

6, Medium pH level:

7, Temperature:

8, Drive type:

9. Power supply:

Contact me for detail offer with curve and drawing!