Basic Info.

Product Description

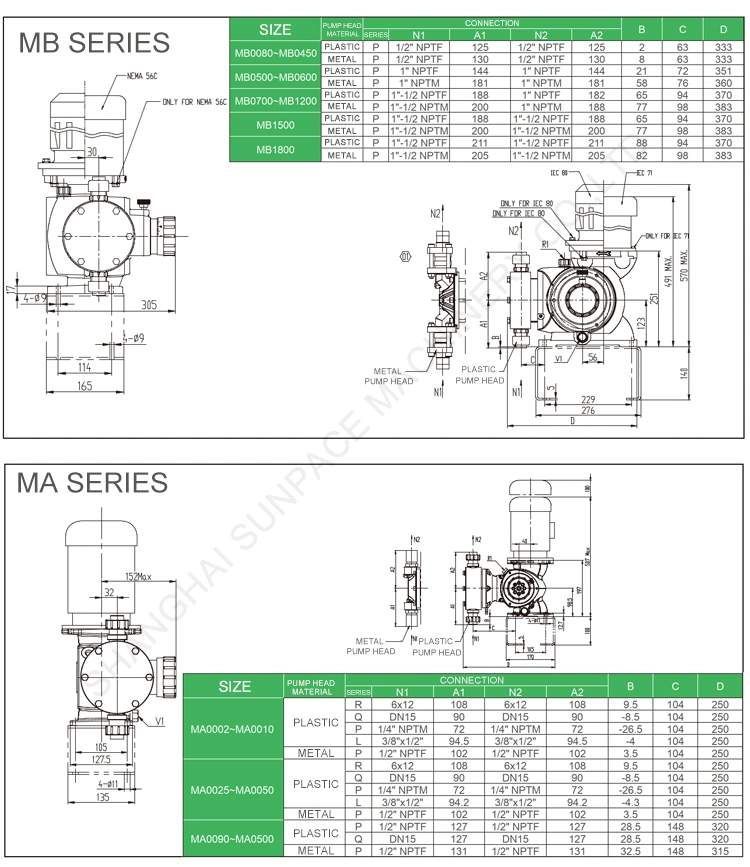

| Main Performance Parameter | |

| Flow Rate | Max 1800 L/H(Single head) |

| Suction Head | Max 3m |

| Discharge Pressure | Max 12bar |

| Suction Pressure | Max 2bar |

| Turndown ratio | 10:1, stability precision ±2% |

| Temperature | Max 40ºC |

| Main Features | |

| Hydraulic end | |

| Mechanical drive diaphragm,without diaphragm guard on the medium side for easy transport. | |

| Various pump head materials such as PVC, PVDF, 316SS, high viscosity, slurry, suitable for various medium. | |

| Self-cleaning check valve structure | |

| Drive end | |

| Adjustable by variable eccentric mechanism to ensure gentle change of flow pulsation | |

| Enhanced structural design, suitable for harsh operating environments | |

| Wear-resistant ball bearings for more stable work | |

| Oil bath lubrication, long working life of drive parts | |

| Flow can be adjusted in stop or running state. The adjustment method can be manual, electric or variable frequency. | |

| Control Method | |

| Electric stroke controller: accept external control signals to adjust stroke length | |

| Power supply | 220V,50HZ, Single phase, 380V,50HZ,3Phase or as required |

| Input signal | 4-20mA analog signal |

| Output signal | 4-20mA / 1-5V analog signal for record display and control system. |

| Motor controller:Control the three-phase motor in the "on / off" mode to adjust the output flow | |

| Power supply | 200-240V/50HZ/60HZ/Single phase |

| Control method | Accept 4-20mA analog signal, external pulse signal or manual adjustment. |

| Input signal | 4-20mA analog signal |

| Variable frequency controller:accept external control signals to adjust stroke speed | |

| Power Supply | 220V-50HZ,Single phase/380V,50HZ,3Phase or as required |

| Input signal | 4-20mA analog signal |

Hydraulic End Main Parts Material

| Hydraulic end material | Hydraulic end | Valve body | Valve seat | Valve ball | Diaphargm | Sealing ring | connection |

| PVC | PVC | PVDF/PVC | PVDF/PVC | Ceramics | PTFE | Fluororubber | PVC |

| PVDF | PVDF | PVDF | PVDF | Ceramics | PTFE | PTFE | PVDF |

| 316SS | 316SS | 316SS | 316SS | 316SS | PTFE | Fluororubber | 316SS |

Application And Typical Medium

| Application | Tap / pure water, power generation, food and beverage, wastewater treatment, chemical, petrochemicals,pharmaceutical, cooling tower boilers, mining, etc. |

| Type Medium | Acid, pH control, catalyst, alkaline polymer, solvent, detergent, bleach, dye / ink, etc. |

If you have any others pump type require, please free contact us.

FAQ

Q:Can you supply pump qualified with ANSI and ASME standard?

A:Yes, our pump compliant with ISO / ASME/ANSI standard.

Q:How to customize pumps and mechanical seals ?

A:Customers could send us application data, we will select suitable pump and seal types, or client could send us drawings, We are well in OEM and ODM.

Q:How can I pay for my items? What is the payment you can provide?

A:Usually by T/T, 30% down payment once PI confirmed, the balance will be paid after inspection and before shipment. L/C at sight

Q:How long is warranty?

A:1 year for main construction warranty.

Q:How long is production lead time?

A:Normally we have stock.

Q:What is the shipping terms you can provide?

A:Depnends on customer's requirements, we can provide different transportantin terms, such as EXW, FOB, CIF.

Q:Who is in charge of after-sales?

A:SUNPACE has professional after sales service team, we will follow up the client's comments and suggest them good solutions. Solve client's problems and keeping the clients profit.

Q:Who is in charge of maintenance?

A:Local agent. If pump running has any problem on site, our local agent will arrival the plant within 24 hours

Send message Get product Offer & Brochure!!

↓↓↓