- Overview

- Product Description

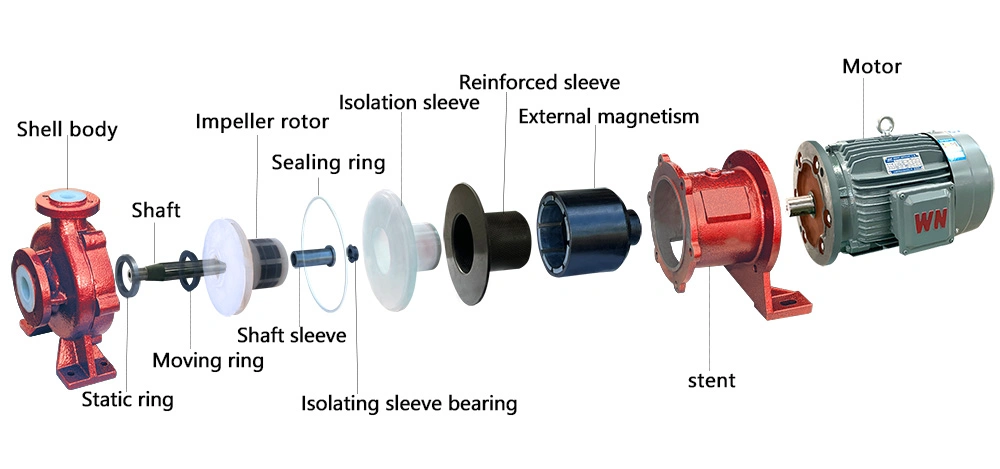

- Part disassembly drawing

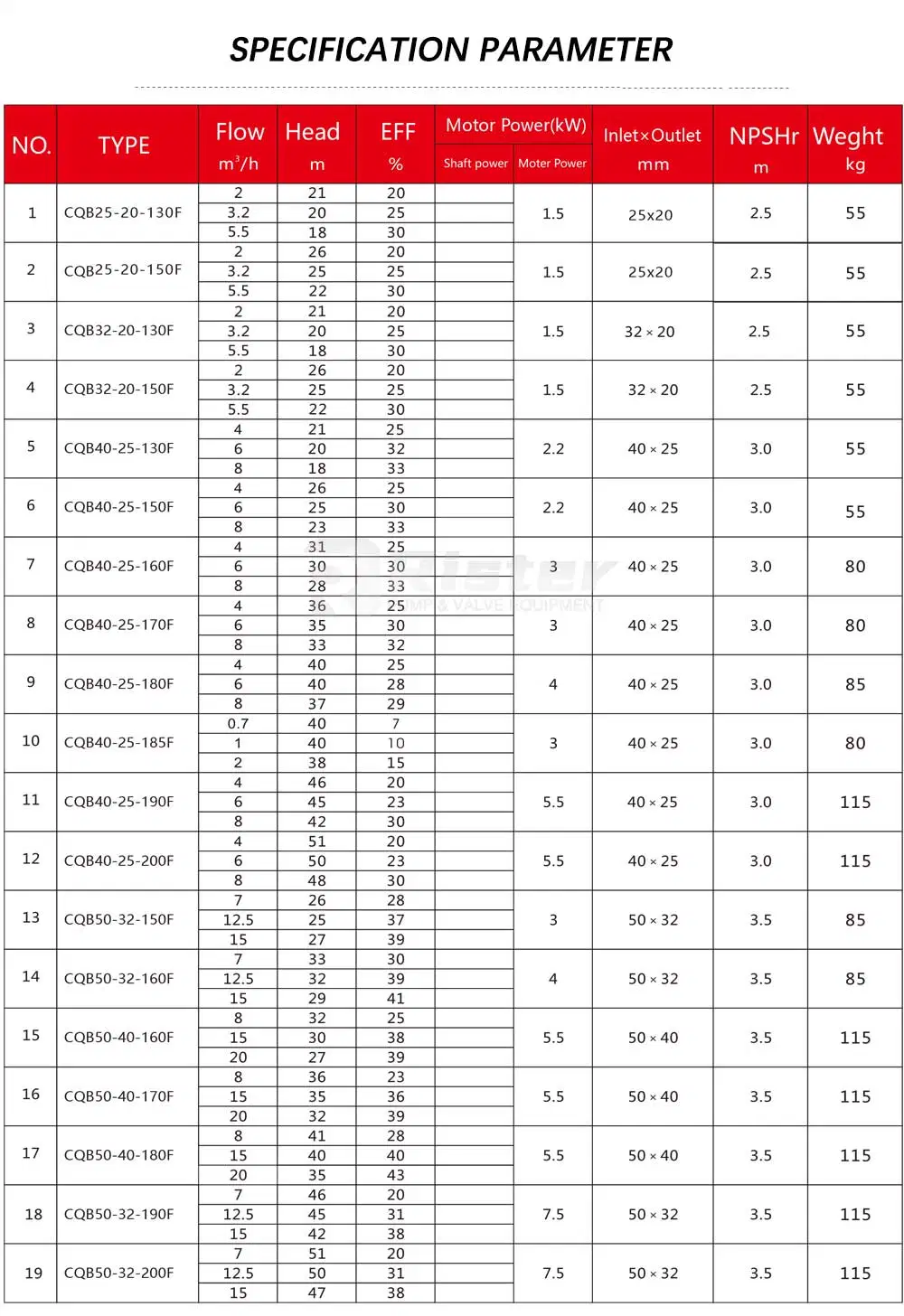

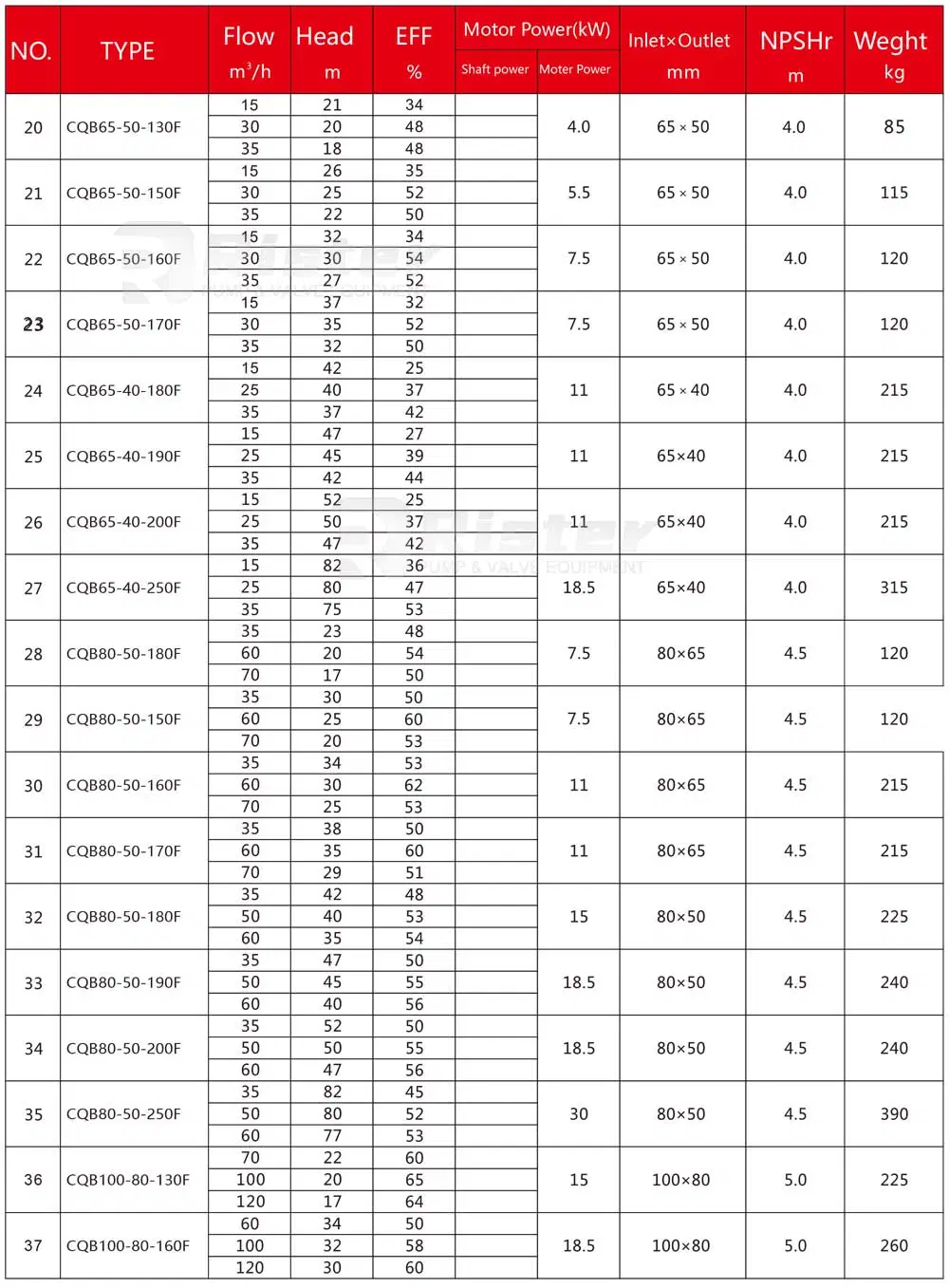

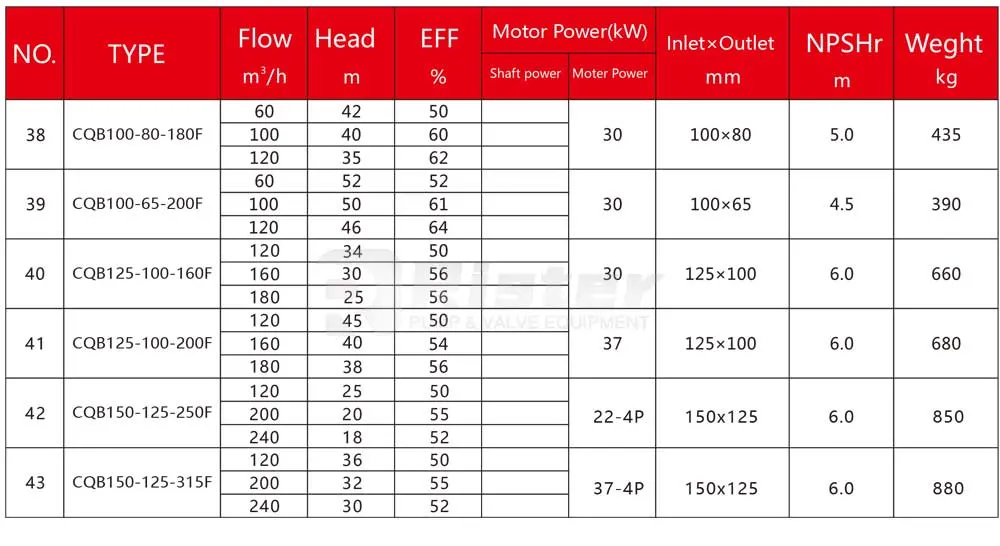

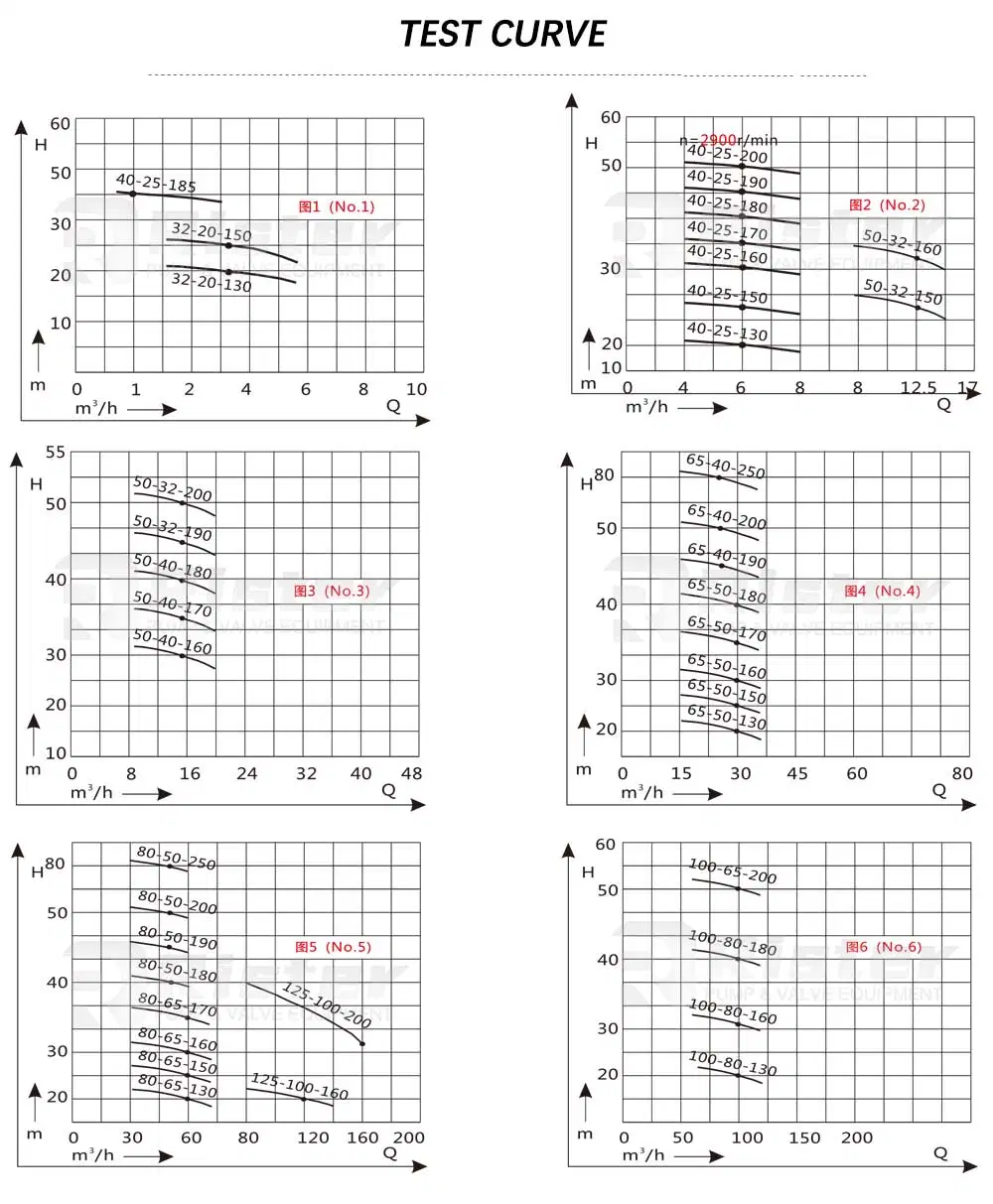

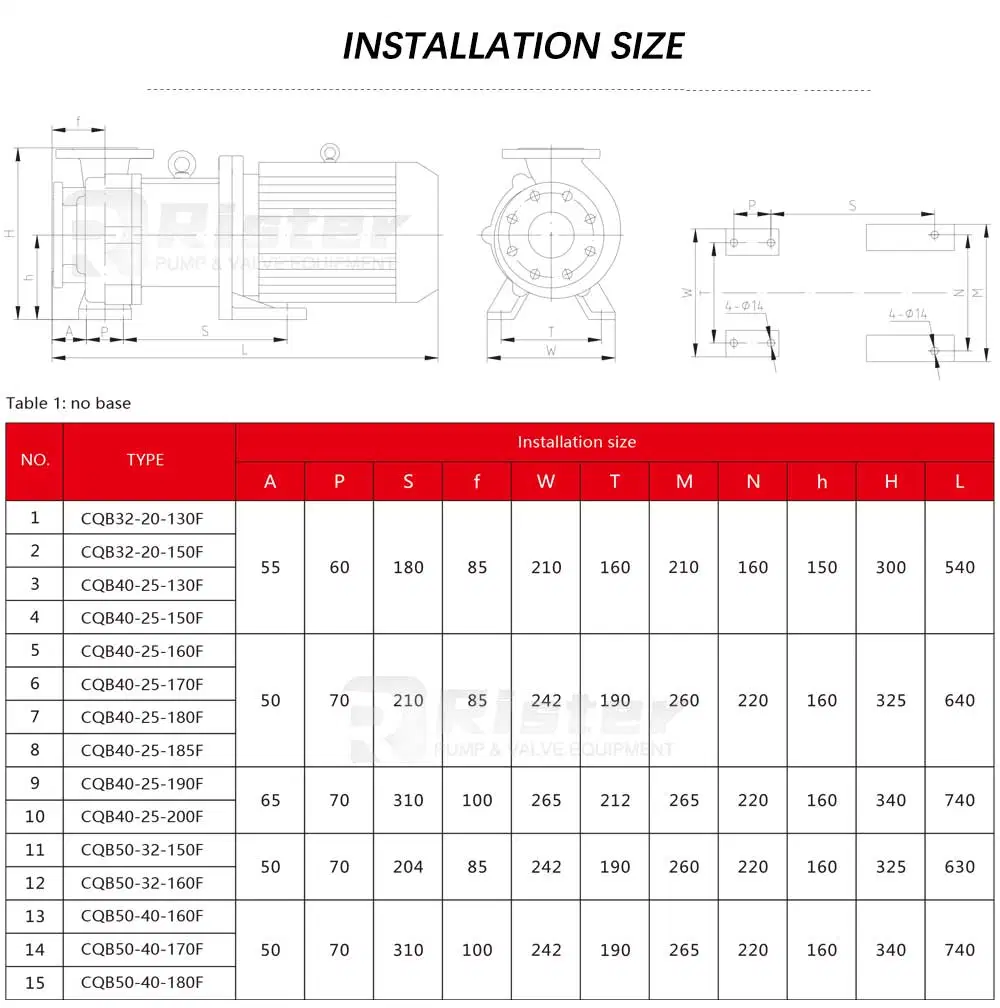

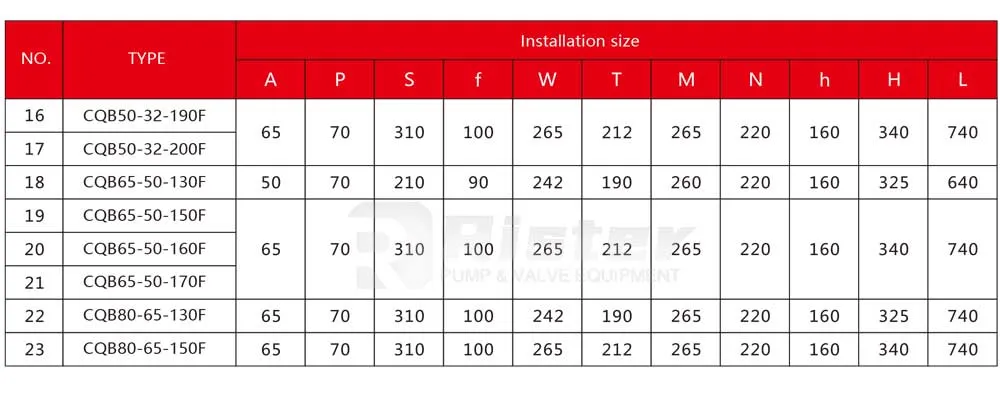

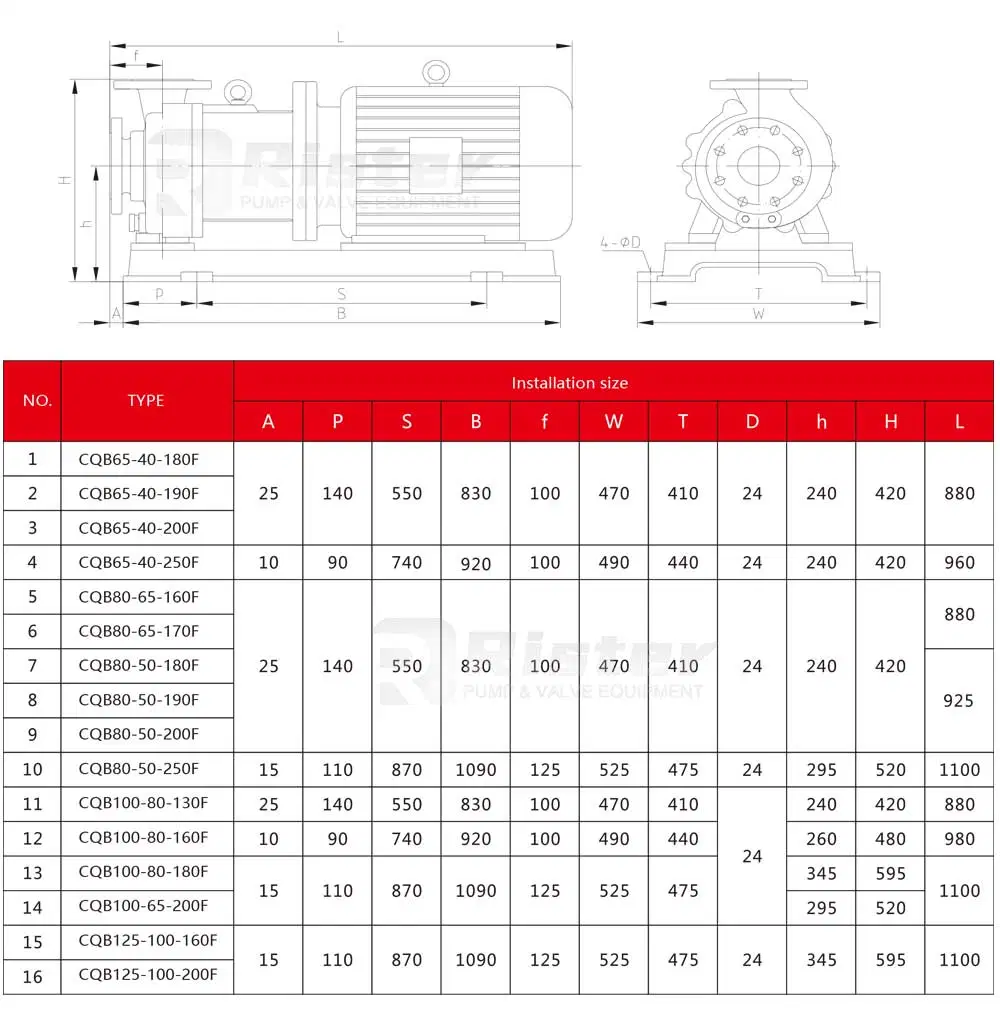

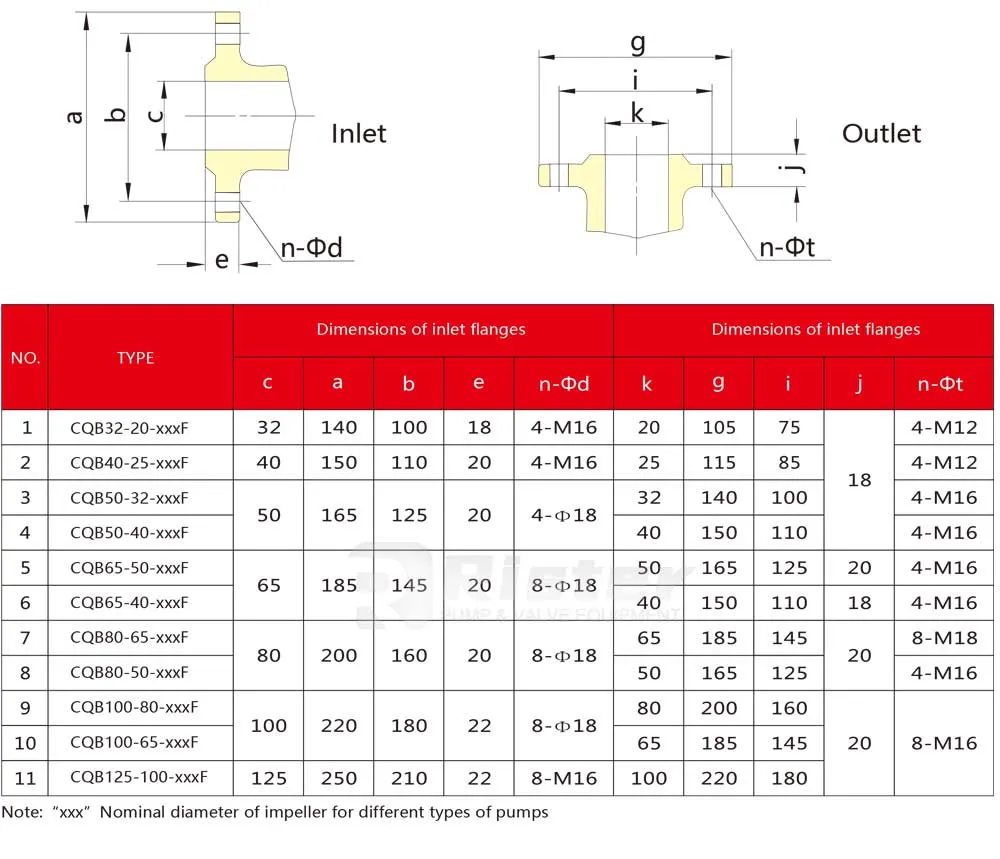

- Product Parameters

- Packaging & Shipping

- FAQ

Basic Info.

Model NO.

CQB-F

Max.Capacity

>400 L/min

Driving Type

Magnetic

Impeller Number

Single-Stage Pump

Working Pressure

Middle Pressure Pump

Influent Type of Impeller

Single Suction Pump

Position of Pump Shaft

Horizontal Pump

Pump Casing Combined

Horizontal Split Pumps

Mounting Height

Since Irrigation Centrifugal Pumps

Impeller

Closed

Usage

Pump, Pumps, Circulating Pump

Model No.

Cqb-F

O-Ring

PTFE/EPDM/FKM/Ffkm

Reinforcing Sleeve

Carbon Fibre

Magnetic Force

Magnetic Drive Pump

Magnet

Rare Earth Magnet

Nominal Pressure

Pn16

Lining

FEP/PTFE/PFA

Flange Connection

DN Standard Design/ANSI B16.5 Class 150

Temperature Range

-20degrees Celsius to 150degrees Celsius

Voltage

200V,220V,380V,400V,415V,440V,480V,600V

Customized Support

OEM, ODM

Eff

20%-64%

Power Source

Electric

Horsepower

1.5kw-37kw

Inlet*Outlet

25*20mm-150*125mm

Transport Package

Wooden Box

Specification

Customized

Trademark

Rister

Origin

Anhui, Xuancheng

HS Code

8413709990

Production Capacity

50000

Packaging & Delivery

Package Size

100.00cm * 50.00cm * 60.00cm

Package Gross Weight

200.000kg

Product Description

https://7db3ae85c2b406f6.en.made-in-china.com/contact-info.html

https://7db3ae85c2b406f6.en.made-in-china.com/contact-info.html Cast iron/HT200 lined FEP/PTFE/PFA fluoroplastic material

Applicable for acid, alkali, chemical solutions, medicne liquids

Simple structure and convenient installation

Easy maintenance

Perfect after sales service

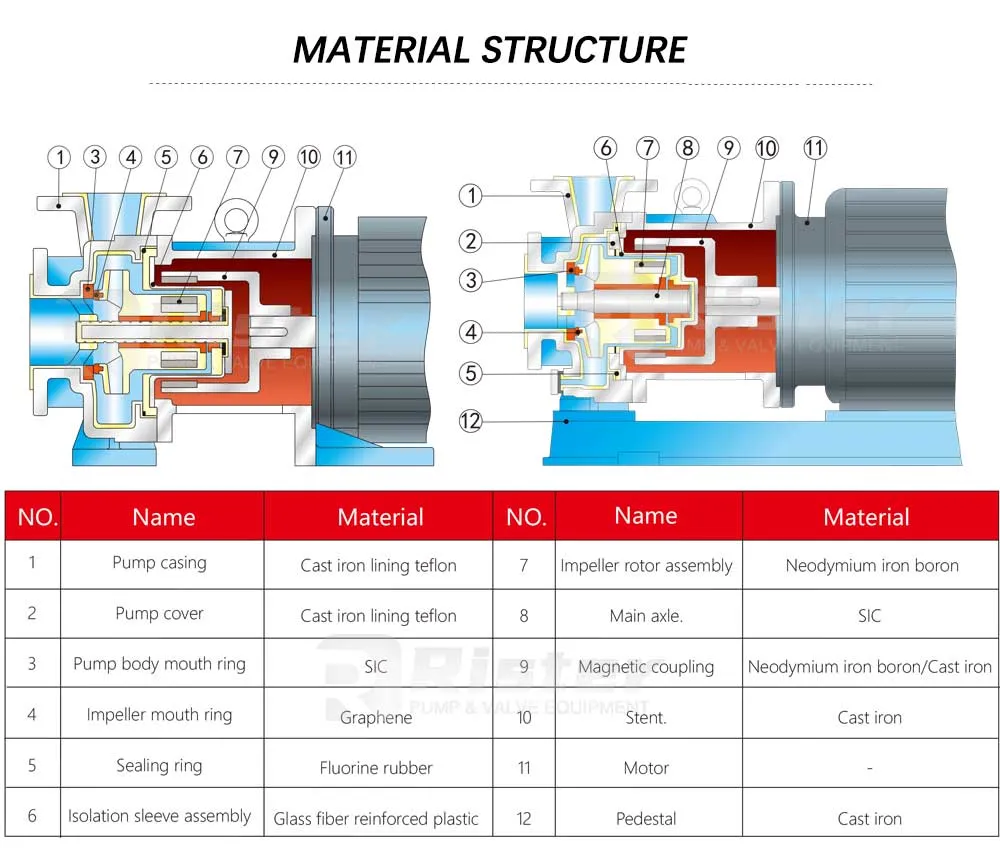

CQB series of pumps uses a variety of new materials, can be different according to the transport medium to replace a variety of suitable materials, it can be customized high temperature type, lye type, granular and so on.

CQB series of pumps are made of all silicon carbide grinding materials ;

The pump shell is made of HT200/F46;

The impeller is made of F46/HdFeB,

and the ring,spindle and shaft sleeve is made of SIC;

The external magnetism is made of HT200/NdFeB.

CQB series of pumps can be used to transport sulfuric acid, nitric acid pump, strong alkali, strong oxidant, organic solvent and other strong corrosive media without damage.

CQB series of pumps can be used in the fields of chlorine, fluorine, benzene, alcohol, into foil, pickling, pesticides, medicine and other industries strong acid medium.

| Application | Biofuel Industry, Drinking water treatment, Food and Beverage Industry, Industrial Boilers, Industrial Utilities, Irrigation and Agriculture, Metal and Equipment Manufacturers, Pharmaceutical industry, Raw Water Intake, Washing and Cleaning, Wastewater Transport and Flood Control, wastewater treatment, Water Treatment Solutions |

| Nominal Pressure: | PN16 |

| Voltage | 200v-600v,or customized |

| Lining: | FEP/PTFE/PFA |

| Housing Material: | Cast iron/HT200 |

| Flange connection: | DN Standard design/ANSI B16.5 Class 150 |

| Temperature Range: | -20ºC to 150ºC. |

| Advantage | Fully enclosed, leak free, corrosion-resistant, low noise, low vibration, small size, easy to operate, easy to maintain, stable and reliable operation. |

https://7db3ae85c2b406f6.en.made-in-china.com/contact-info.html

https://7db3ae85c2b406f6.en.made-in-china.com/contact-info.html

https://7db3ae85c2b406f6.en.made-in-china.com/contact-info.html

https://7db3ae85c2b406f6.en.made-in-china.com/contact-info.html

1. Q: Are you a manufacturer or trading company?A: We are a professional chemical pumps manufacturer, which is located at Wan Neng West Road, West Development Zone, Jing Xian, Xuancheng City, Anhui Province, China.

2. Q: How to customize pumps and mechanical seals ?

A: Customers can send us application data, we will select suitable pumps and seal types, or client can send us drawings, We are well in OEM and ODM.

3. Q: How can I pay for my items? What is the payment you can provide?

A: Usually by T/T, 30% down payment once PI confirmed, the balance will be paid after inspection and before shipment. L/C at sight.

4. Q: What information I need to offer for quotation?

A: Medium: ____________

PH: ________

Specific Gravity: _______

Temperature: _________

Capacity/Flow: ________m3/h

Head: _________m

Voltage: ____________V

Frequency: _________Hz

Power:_____________KW

5. Q: What is your minimum quantity?

A: One set is also welcomed to us.

6.Q:How long is warranty?

A:1 year for main construction warranty.

7.Q:How long is production lead time?

A: Normally 10 days. If client need urgently, we have a huge spare parts stock, we could finish assembly and testing in 3-5 days.

8.Q:What is the shipping terms you can provide?

A:Depnends on customer's requirements, we can provide different transportantin terms, such as EXW, FOB, CIF, CFR.