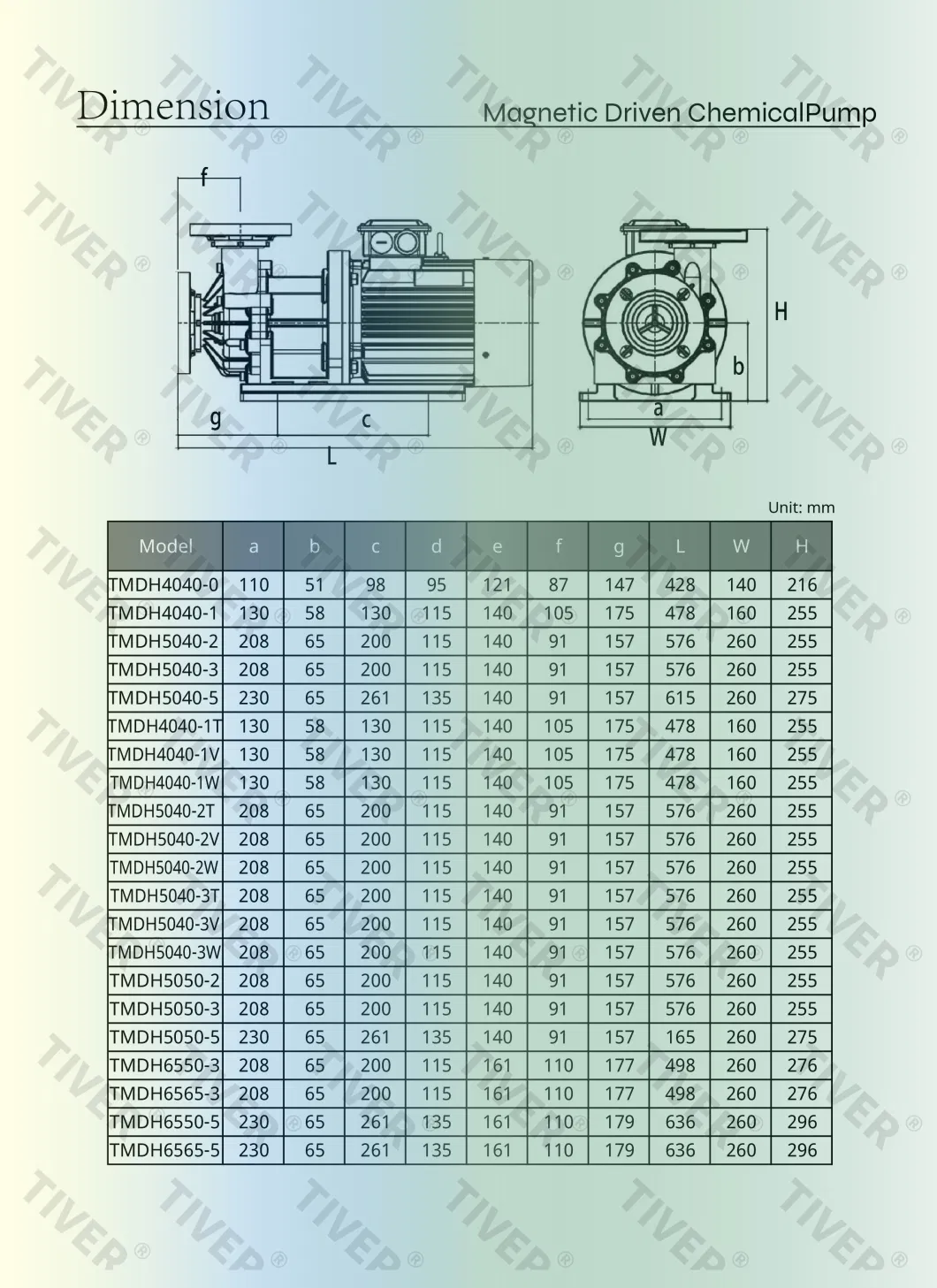

Basic Info.

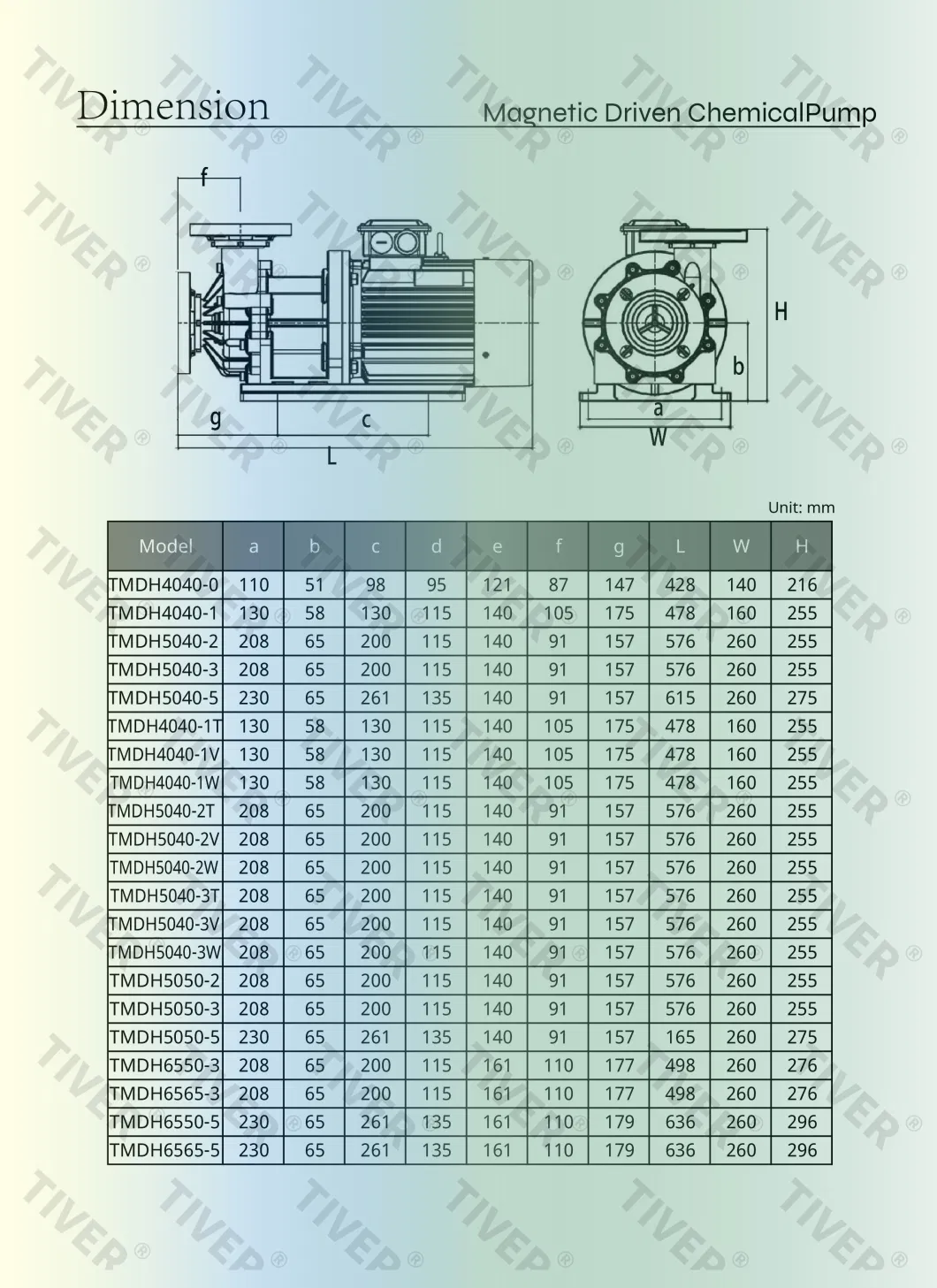

Structure

Single-stage Pump

Assembly

Liquid Pumps

Power

Electric

Start Up

Electric Pump

Type

Blade Pump

Application

Clarified Water Pump, Sewage Pump, Slurry Pump, Oil Transfer Pump, Chemical Pump

Industry

Mechanical Pump

Media

Sewage Pumps

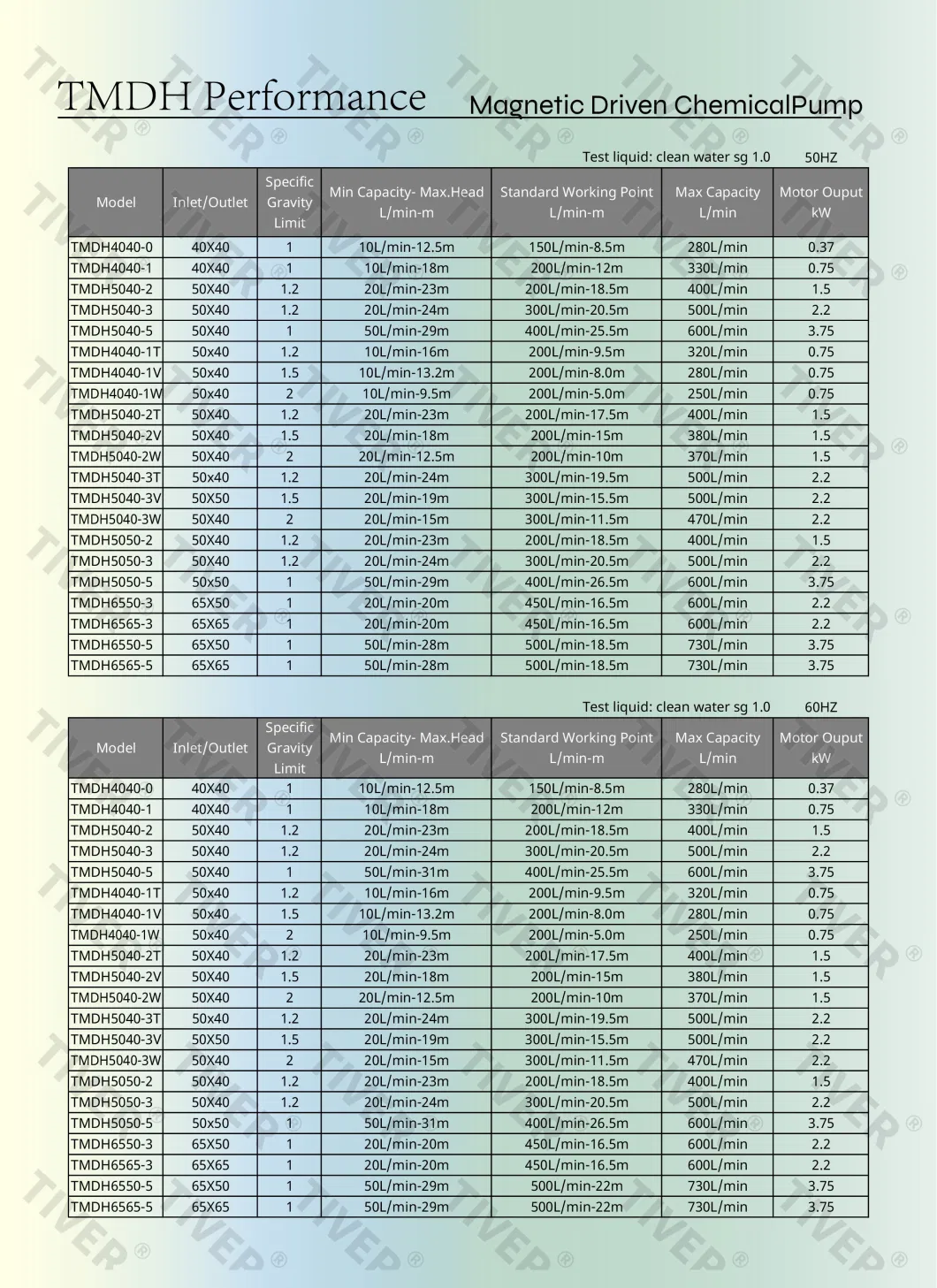

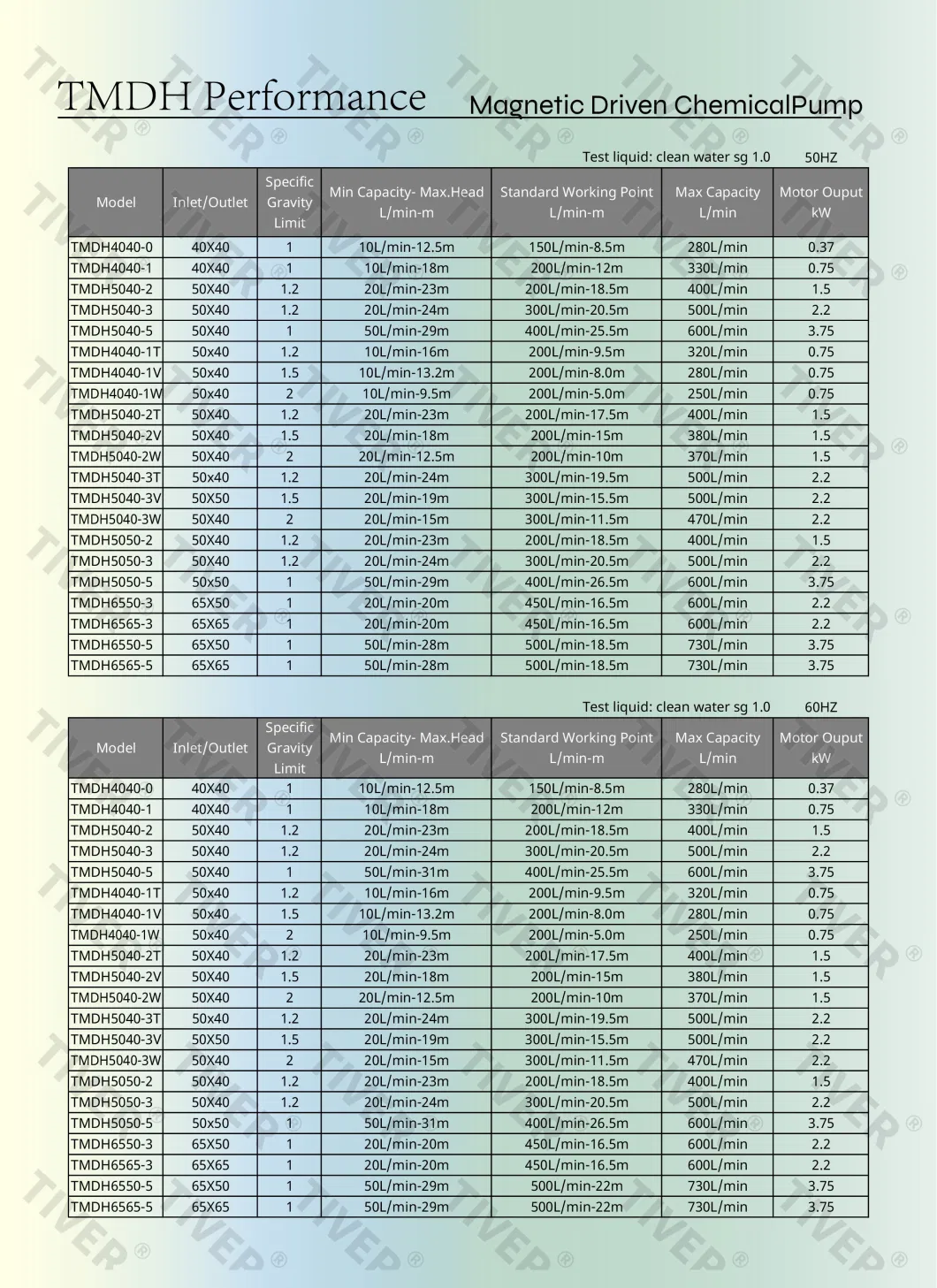

Performance

No Leakage Pump

Theory

Centrifugal Pump

Transport Package

Wooden Case

Origin

China

Production Capacity

10000 PCS/Year

Product Description

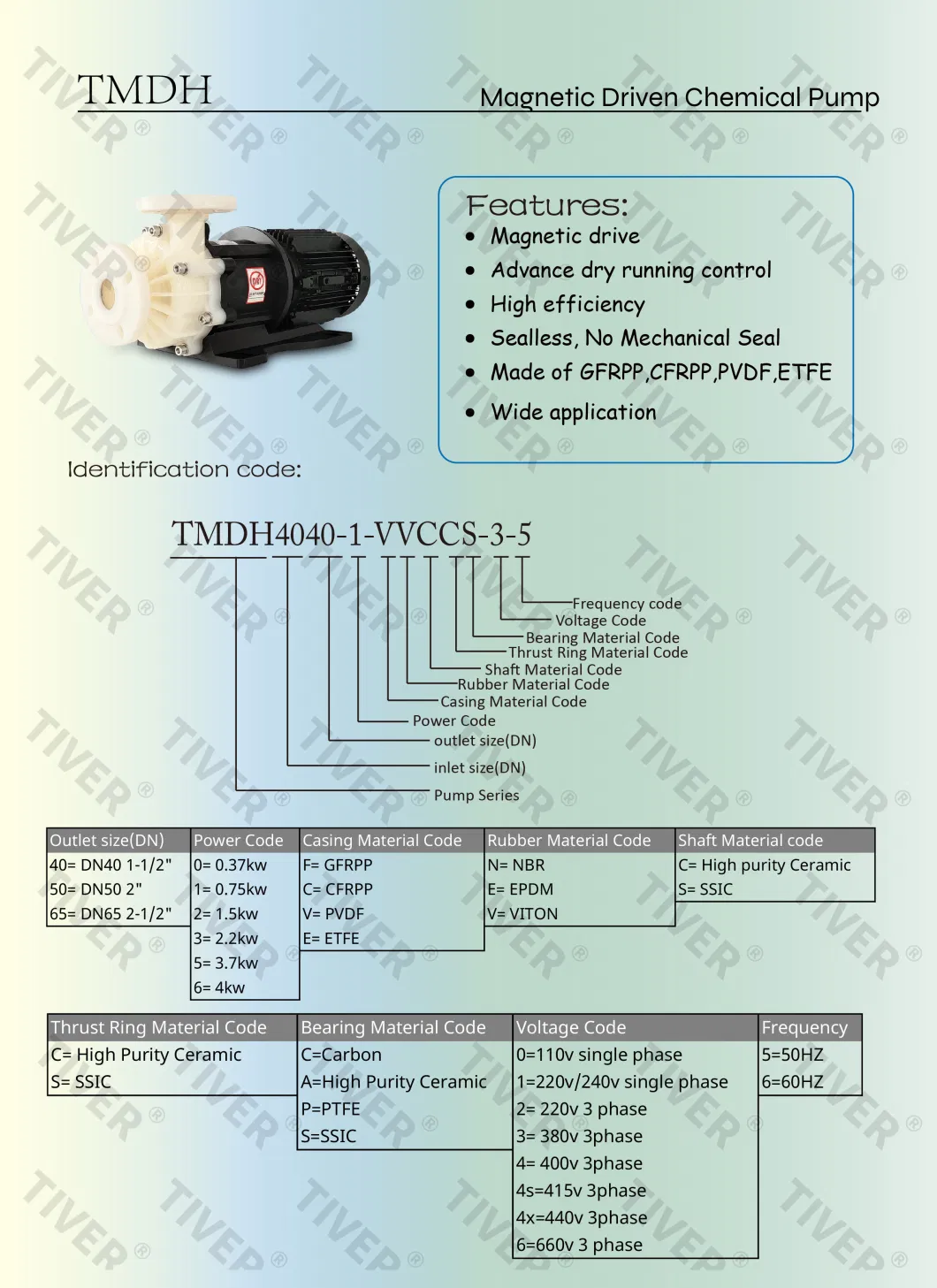

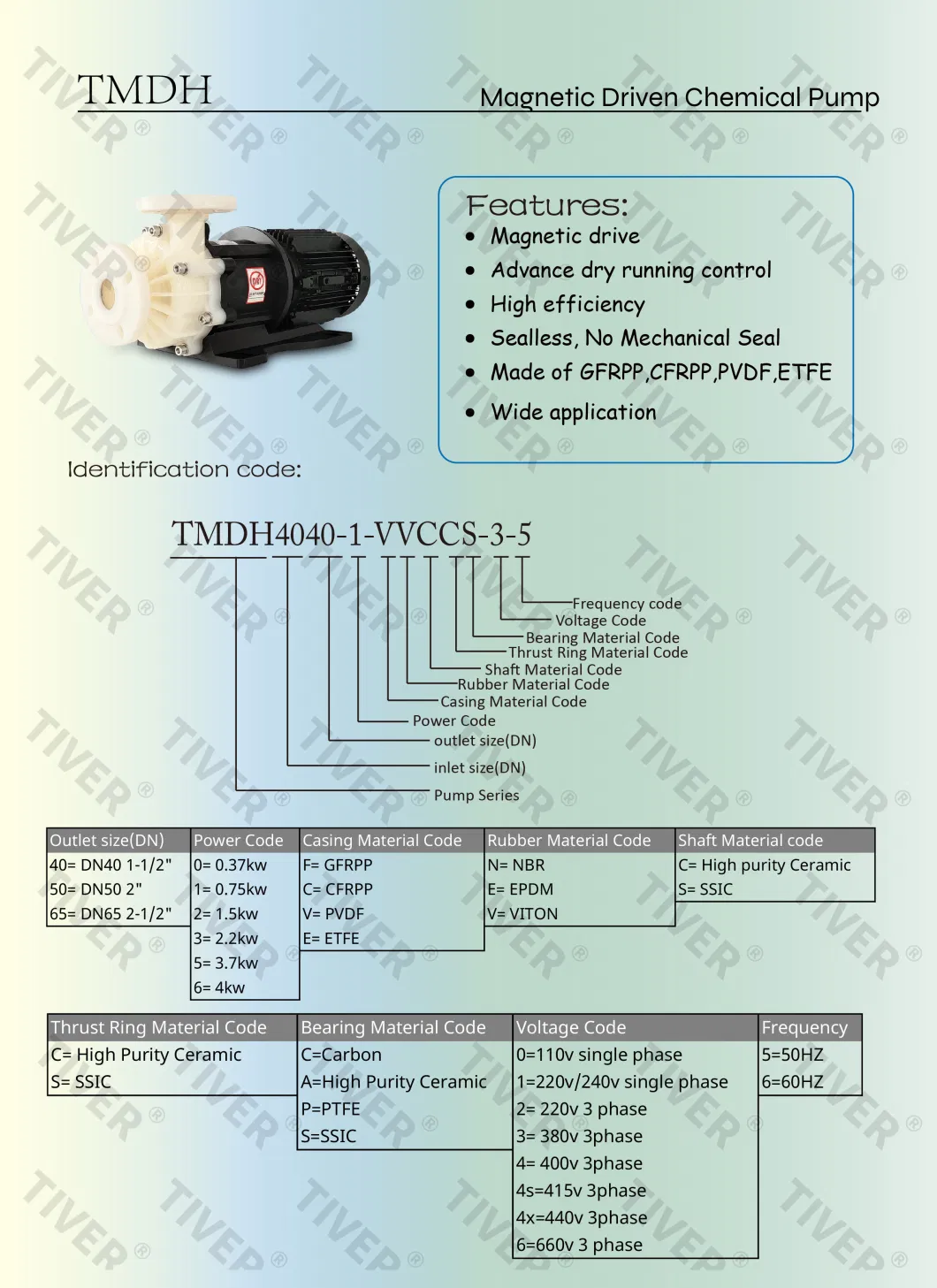

TMDH MAGNETIC DRIVEN CHEMICAL PUMP (SEALLESS WATER PUMP)

TMDH pump technology has produced an innovative magnetic driven chemical pump which incorporates an extremely high resistance to dry running. By applying the newly developed magnet force control system, dry running which was unavailable with previous models. Now a feature on the new magnetic drive pump series. The TMDH/-F series, with its increased durability and reliability, will further demonstrate its usefulness and convenience as corrosion resistant pumps for up to 800L/min.

Why Choose TMDH?

Excellent durability

The pump body parts for TMDH are reinforced by PPH, PP+GF , PP+CF and TMDH-F is

reinforced with ETFE / ETFE+CF. For the purpose of enhancing durability. In addition, sufficient consideration was given to the mechanical strength and the safety of the spindle.

Up to one hour of continuous dry running is possible due to our newest magnet force control system which minimizes the heat generated by bearing surfaces during dry running.

Note: Dry running is possible with carbon bearing.

Excellent corrosion resistance

The casings, impeller assembly and magnet capsule of TMDH pump are made of polypropylene and TMDH-F are made of fluororesin. Other

wet-end parts are made of highly corrosion resistant materials such as carbon, ceramics , Sic and titanium. The pumps can handle most types of chemicals including acids and alkalies.

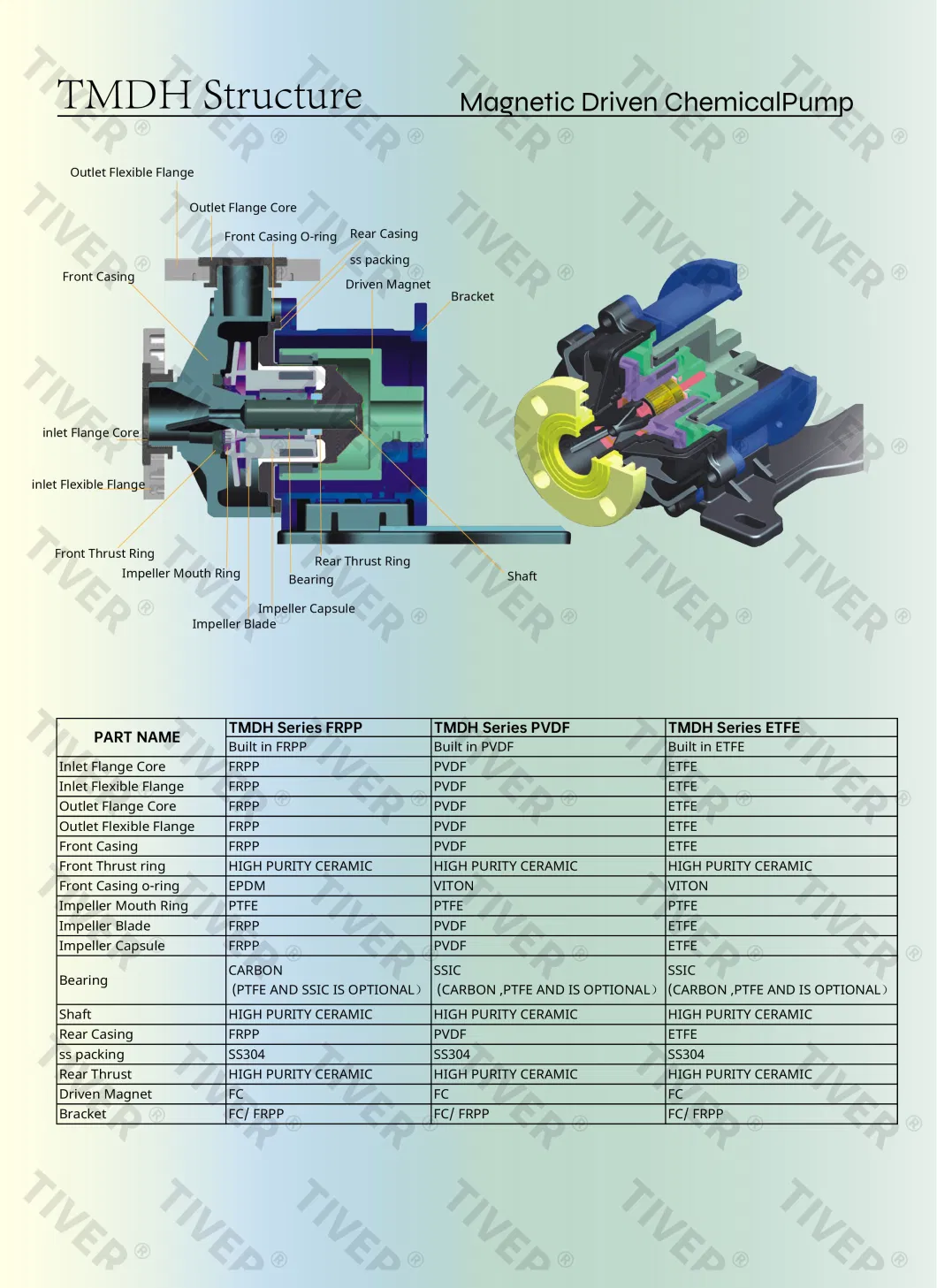

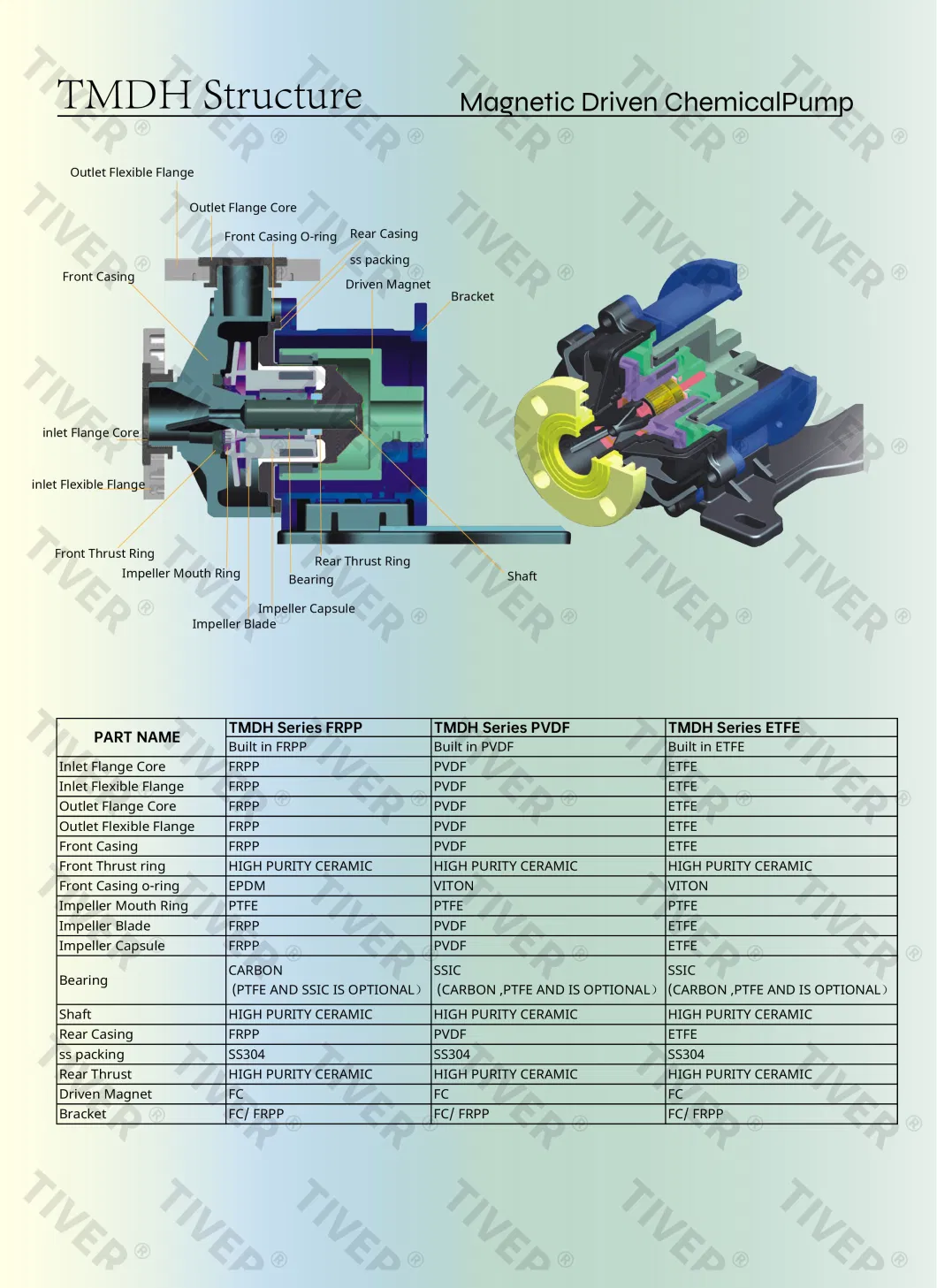

Simple structure

The pump unit's simple structure consists of only a few parts. The assembly and disassembly procedures for maintenance purposes are very easy and simple.

Main Features:

1. Latest "Magnet force control system" , now dry running is available. (optional)

2. Excellent energy saving. save more 20% than usual.

3. Whole casing and impeller group are injection structure, no welding, resist high temperature, high pressure and can

prevent distortion and leakage after running for long time.

4. Low price for spare parts. Easy to maintan.

5. Flange is removabvle. Flange can fit DIN, JIS , ANSI standard.

TMDH pump technology has produced an innovative magnetic driven chemical pump which incorporates an extremely high resistance to dry running. By applying the newly developed magnet force control system, dry running which was unavailable with previous models. Now a feature on the new magnetic drive pump series. The TMDH/-F series, with its increased durability and reliability, will further demonstrate its usefulness and convenience as corrosion resistant pumps for up to 800L/min.

Why Choose TMDH?

Excellent durability

The pump body parts for TMDH are reinforced by PPH, PP+GF , PP+CF and TMDH-F is

reinforced with ETFE / ETFE+CF. For the purpose of enhancing durability. In addition, sufficient consideration was given to the mechanical strength and the safety of the spindle.

Up to one hour of continuous dry running is possible due to our newest magnet force control system which minimizes the heat generated by bearing surfaces during dry running.

Note: Dry running is possible with carbon bearing.

Excellent corrosion resistance

The casings, impeller assembly and magnet capsule of TMDH pump are made of polypropylene and TMDH-F are made of fluororesin. Other

wet-end parts are made of highly corrosion resistant materials such as carbon, ceramics , Sic and titanium. The pumps can handle most types of chemicals including acids and alkalies.

Simple structure

The pump unit's simple structure consists of only a few parts. The assembly and disassembly procedures for maintenance purposes are very easy and simple.

Main Features:

1. Latest "Magnet force control system" , now dry running is available. (optional)

2. Excellent energy saving. save more 20% than usual.

3. Whole casing and impeller group are injection structure, no welding, resist high temperature, high pressure and can

prevent distortion and leakage after running for long time.

4. Low price for spare parts. Easy to maintan.

5. Flange is removabvle. Flange can fit DIN, JIS , ANSI standard.