- Overview

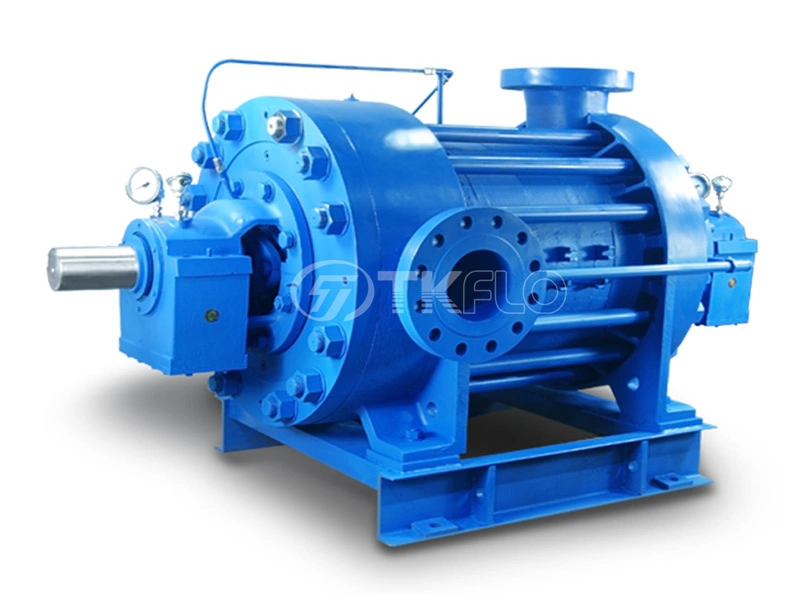

- Product Description

- Operation Parameter

- Application

- Product Advantage

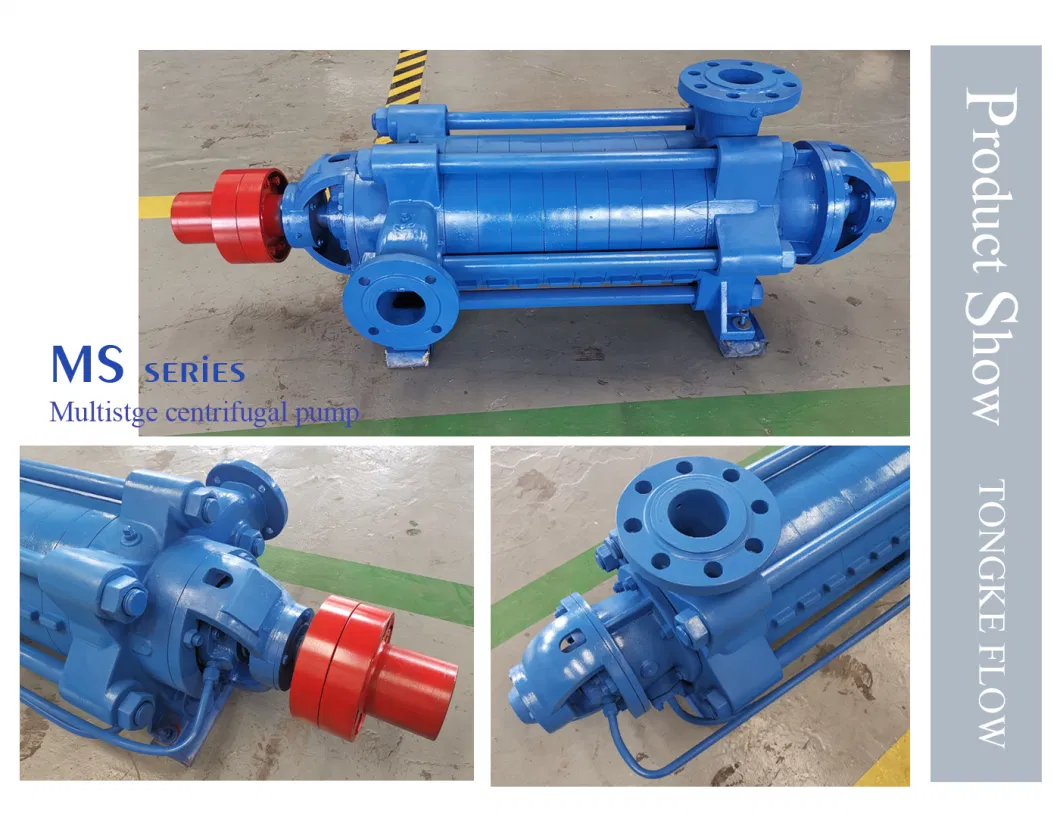

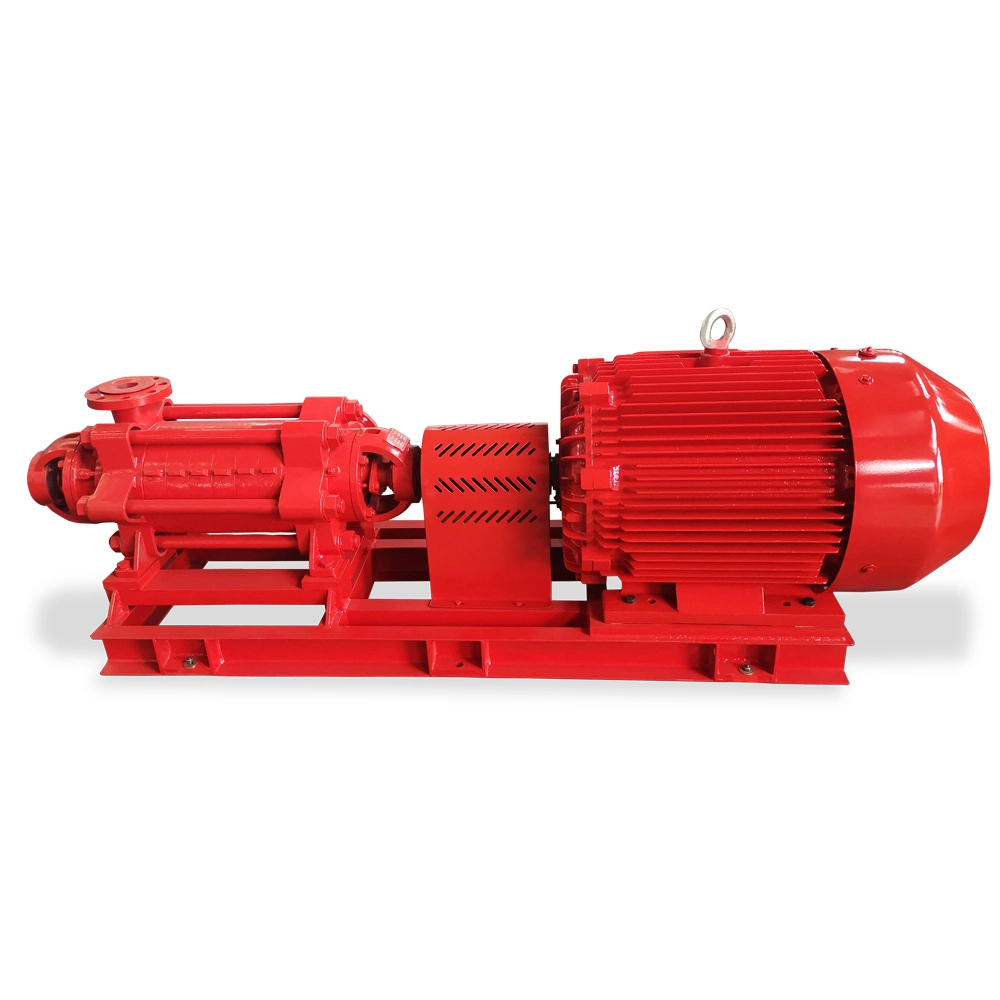

- <span style="font-family:Calibri;">Detailed Photos</span>

- FAQ

- <span style="font-family:Calibri;"><span style="font-size:16px;">Company Profile</span></span>

Basic Info.

Product Description

Note: When the situation is in the coal mine, explosion proof type motor shall be used.

API Chemical multisatge high pressure pump

Vertical multisatge centrifugal pump.

Pleasr refer to https://tkflow.en.made-in-china.com/product-list-1.html

A multistage pump operates by one impeller feeding into the next impeller and the number of impellers required depend on the discharge pressure requirement. Liquid enters the pump and then passes through the various number of impellers in a sequence from the left to right.

TKFLO pump operation parameter as follow:

| Diameter | DN 80-250 mm |

| Capacity | 25-500 m3/h |

| Head | 60-1798m |

| Liquid Temperature | up to80 ºC |

∧ Water supply & drainage for mines

∧ High buildings life water supply, fire fighting system, automatic spraying water under the water curtain, long distance water transportation, water circulation in production process, supporting the use of all kinds of equipment and various production process water, etc

∧ Hotels, restaurants, entertainment refrigeration and air conditioning supply water

1.Compact structure nice appearance, good stability and easy installation.

2.Stable running the optimally designed double-suction impeller makes the axial force reduced to the minimum and has a blade-style of very excellent hydraulic performance, both internal surface of the pump casing and the impeller s surface, being precisely cast, are extremely smooth and have a notable performance vapor corrosion resisting and a high efficiency.

3. The pump case is double volute structured, which greatly reduces radial force, lightens bearing's load and long bearing's service life.

4.Bearing use FAMOUS BRAND bearings to guarantee a stable running, low noise and long duration.

5.Shaft seal use FAMOUS BRAND mechanical or stuffing seal to ensure a 8000h non-leak running.

6 . Flange standard: GB, HG, DIN, ANSI standard, according to your requirements.

Description of structure

Model MS pump consists of four parts, stator, rotor, bearing and shaft seal:

1.Stator consists of inlet, middle and outlet sections and the guide vane etc., with the take-up bolt tightly clamping all sections to form a working room. The inlet of it stands horizontally while the outlet vertically upward.

2.Rotor consists of the shaft, impeller, balancing disk and muff etc., the shaft passes the power to the impeller to have it work; the balancing disk balances the axial force; and replaceable muff is mounted on both sides of the shaft to protect it.

3.There are rolling and sliding bearings:

The rolling bearing consists of bearing seat, bearing and bearing gland and uses grease for lubrication.

The sliding bearing consists of bearing body and cover, liner, dust-proof disk, oil leveler, oil throwing ring etc., and uses thinned oil for lubrication.

4. The shaft is sealed with stuffing and the shaft seal consists of the sealing contents, stuffing, baffle. The liquid in the sealing work-room functions water-sealing, water cooling and water lubricating and the water for water sealing comes from the pressure water inside of the pump.

In addition, the pump is directly actuated by the prime mover through the elastic clutch and, viewing from the prime mover, moves CW.

Here is the structural drawing supported with the rolling bearing, more structural contact TKFLO.

Recommended Material Configuration

| Recommended Material Configuration (For reference only) | |||

| Inlet suction | Cast iron/Carbon steel | Seal-ring | Cast iron/ Carbon steel |

| Outlet suction | Cast iron/ Carbon steel | Guide vane sleeve | |

| Middle suction | Cast iron/ Carbon steel | Impeller sleeve | Stainless steel/ steel |

| Guide vane | Cast iron/ Carbon steel/Stainless steel | Balancing sleeve | QT500-7 /stainless steel 3Cr13 /steel 45# |

| Impeller | Cast iron/ Carbon steel/Stainless steel | Balancing ring | 35 overlay welded alloy |

| Shaft | Steel 45#/ Stainless steel 40Cr, 35 CrMo | Balancing disk | 35 overlay welded alloy |

| Remarks: To satisfy requirements for customers. The proper requirements of materials above for pump part can be used according to contracts. | |||

NOTE before order

Parameters necessary to be submitted at order.

1. Pump model and the flow, head (including the system loss), NPSHr at the point of the desired working condition.

2. Type of shaft seal (must be noted either mechanical or packing seal and, if not, delivery of the mechanical seal structure will be made).

3. Moving direction of the pump (must be noted in case of a CCW installation and, if not, delivery of a clockwise installation will be made).

4. Parameters of the motor (Y series motor of IP44 is generally used as the low-voltage motor with a power <200KW and, when to use a high voltage one, please note its voltage, protective rating, insulation class, way of cooling, power, number of polarity and manufacturer).

5. The materials of pump casing, impeller, shaft etc. parts. (delivery with the standard allocation will be made if without being noted).

6. Medium temperature (delivery upon a constant-temperature medium will be made if without being noted).

7. When the medium to be transported is corrosive or contains solid grains, please note the features of it.

Multi-stage centrifugal pumps come with two outer bearings, a seal pressure-balancing line that discharges pressure from the seal section on the discharge side back to the suction side. Due to this unique design, more economical sealing arrangements can be used, even when the pump works under high pressures.

The pumps are offered in different sizes based on the application and volume. Smaller multi-stage centrifugal pumps suffice for heating plants, fire-fighting operations, water pipelines, irrigation, agriculture, boiler feed, autoclaves, hydrocarbons, and carrying lightly soiled but also clean liquids.

Q1. Are you a manufacturer?

Yes, we have been in pumps manufacturing and oversea marketing industry over 15 years.

Q2. What markets do your pumps export to?

More than 20 countries and areas, such as South-East Asia, Europe, North & South America, Africa, Oceanic, Middle East countries...

Q3. What information should I let you know if I want to get a quotation?

Please let us know the pump capacity, head, medium, operation situation, quantity, etc. As much as your provide, the precision and accurate model selection.

Q4. Is it available to print our own brand on the pump?

Totally acceptable as international rules.

Q5. How can I get the price of your pump?

You can connect with us through any of the following contact information. Our personalized service person will respond you within 24 hours.

The short answer to "what is a multistage centrifugal pump used for?" is that it depends on the type of pump, but many applications can benefit from these pumps. Multi-stage centrifugal pumps are popular pumps in different applications. Their capability to provide a flexible range of flow and head for engineers, along with their high energy efficiency, makes them an excellent choice for many purposes.

Q7. What is a Multi-Stage Centrifugal Pump

Multistage centrifugal pumps are manufactured with two or more impellers. The rotors can be installed on the same or different shafts depending on the configuration. If high pressures of outflow are required, the rotors can also be joined in series. However, in the case of high capacity requirements, they are often connected in parallel.

Multistage centrifugal pumps are applied to make high pressure on the Shaft in the same housing, which is more economical than a pump with a single impeller. As part of the pump structure, the channels within the pump housing work by directing an impeller discharge to suck the other.

Water enters the pump and passes through an assembly of rotors in series, from left to right. From there, water flows from the spiral around the spiral of one rotor to make suction for the next rotor. Usually, these types of pumps are single-stage pumps. A multistage centrifugal pump has a much better performance.

In some cases of multi-stage centrifugal pumps, axial pressure forces can be balanced by balancing blades installed at the rear of the impellers. The angular ball bearing on the drive side and the heavy-duty ball bearing on the drive side are used to absorb the remaining forces.