Basic Info.

Model NO.

65QV-SP

Influent Type of Impeller

Single Suction Pump

Position of Pump Shaft

Vertical Pump

Pump Casing Combined

Verticaljoint Surface Pump

Mounting Height

Since Irrigation Centrifugal Pumps

Impeller

Closed

Usage

Pump, Pumps, Condensate Pump, Slurry Pump, Circulating Pump, Closed Impeller Sludge Pump

Size

65mm

Capacity

18-113m3/H

Head

5-31.5m

Max.Power

15kw

Handing Solids

15mm

Speed

700-1500rpm

Submerged Length

900-2800mm

Materials

High Chrome Alloy, Rubber, Polyurethane etc

Transport Package

Wooden Case

Trademark

Tobee

Origin

China

Production Capacity

10000

Product Description

Vertical Slurry Pump Product Description

Tobee® industrial centrifugual electric vertical spindle pump is available in various standard lengths to suit common sump depths, for very deep sumps or where high shaft speeds limit the length of the pump, a suction extension pipe can be fitted to the bottom inlet to extend the depth of the pump by up to 2 meters. Pumping is maintained even when the top inlet is not submerged, thus enabling the level of liquid to be lowered right down to the bottom inlet or the bottom of any suction extension pipe. The wet parts of SPR vertical sump pump is interchangeable with the SP series hard metal lined heavy duty sump pumps.

Design Features:

√ Less wear, less corrosion

Wetted components are available in a wide range of alloys and elastomers, from which Weir Minerals selects the optimum combination of materials for maximum resistance to wear in virtually any industrial application, including those demanding both abrasion and corrosion resistance and where larger particles or high density slurries are encountered.

• Abrasion resistant A05 Ultrachrome® alloy.

• Abrasion/corrosion-resistant A49 Hyperchrome® alloy.

• Corrosion-resistant stainless steels.

• Natural and synthetic elastomers.

√ No submerged bearing failures

The robust cantilever shaft avoids the need for lower submerged bearings - which are often the source of premature bearing failure.

• Heavy duty roller bearings, above mountingplate.

• No submerged bearings.

• Labyrinth/flinger bearing protection.

• Rigid, large diameter shaft.

√ No shaft sealing problems

The vertical cantilever design requires no shaft seal.

√ No priming required

The top and bottom inlet design is ideally suited for "snore" conditions.

√ Less risk of blocking

The screened inlets and large impeller passages reduce the risk of blockages.

√ Zero ancillary water costs

The vertical cantilever design with no gland or submerged bearings avoids the need for expensive gland or bearing flushing water.

Tobee® SP/SPR Vertical Slurry Pumps Performance Parameters:

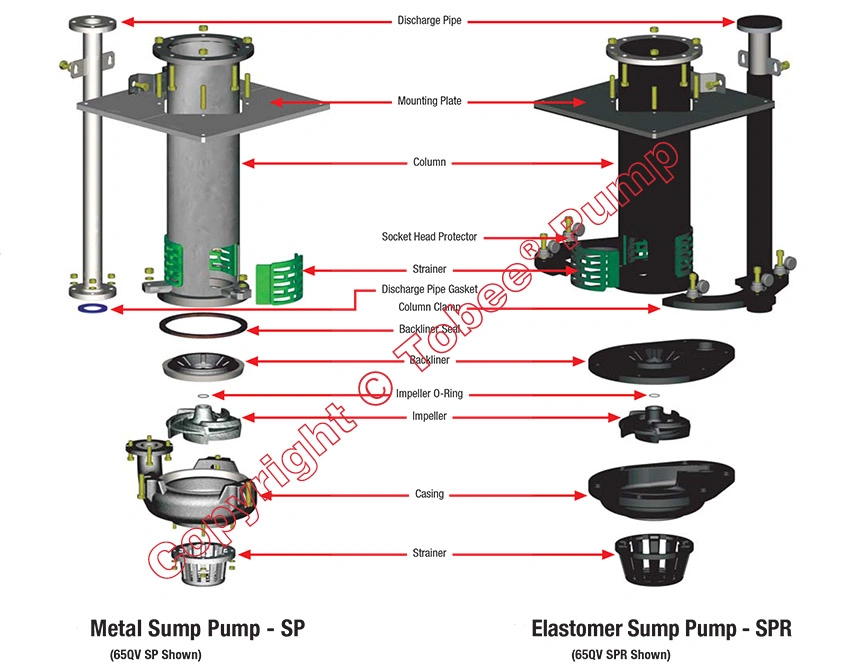

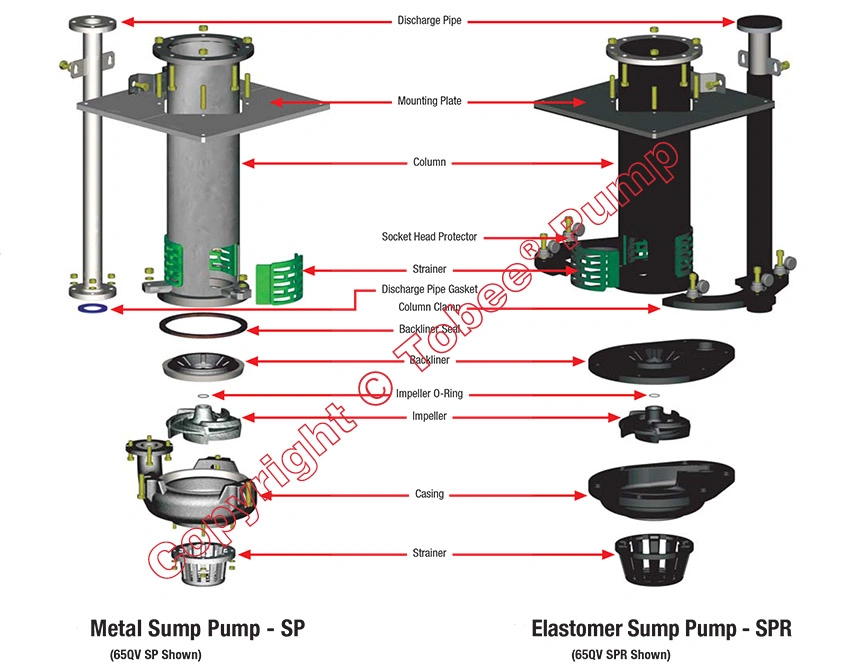

Tobee® SP/SPR Vertical Slurry Pumps Structural Drawing:

Tobee® SP/SPR Vertical Slurry Pumps Applications:

The SP/SPR verical slurry pumps are available in a wide range of popular sizes to suit most pumping applications. The SP/SPR sump pumps are proving their reliability and efficiency worldwide in: minerals processing, coal preparation, chemical processing, effluent handling, sand and gravel and almost every other tank, pit or hole-in-the ground slurry handling situation. The SP/SPR pump design with either hard metal (SP) or elastomer covered (SPR) components makes it ideal for abrasive and/or corrosive slurries, large particle sizes, high density slurries, continuous or "snore" operation, heavy duties demanding cantilever shafts

Company Information

Introduction

Hebei Tobee Group Co.,Limited, is a professional manufacturer in designing and manufacturing Slurry Pumps, Pipe & Fitting, Valve etc. Our factory is located in the High tech Development Zone, Shijiazhuang City, China. We specialized in Horizontal Slurry pump, Vertical slurry pump, Gravel sand pump, Dredging pump, Double suction pump, End suction pump, Multistage pump, Boiler feed water pump, Self priming pump, Inline centrifugal pump, Sea water pump, Chemical pump, Irrigation pump, Fire pump, API 610 centrifugal oil pump, Submersible slurry pump, Hydraulic slurry pump, Hydraulic dredge pump, Submersible sewage pump, Slurry Pump spares,Pipe & fittings and Valve in domestic and else in the world.

Capacity

Tobee® Pump has a wealth of experience in the manufacturing and service of pumps and accessories; in fact Tobee® Pump has machinery manufacturing experience of over 45 years having achieved great success with R&D and manufacturing of Pumps for more than 30 years. The annual production capacity of pumps in our factory surpasses 10,000 easily. Tobee® Pump has a tremendous market share that covers more than 30 cities in China including many provinces and autonomous regions and more than 80 countries.

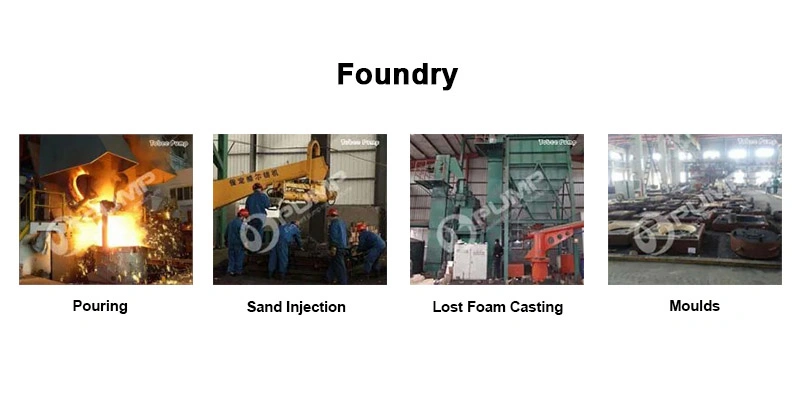

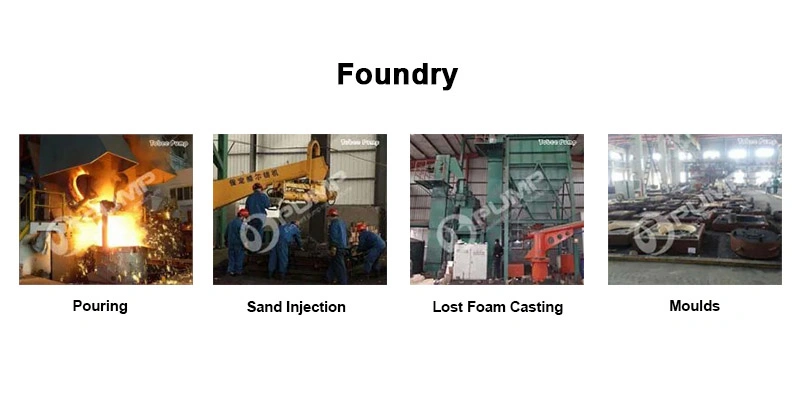

Production Capability

Tobee® Pump has over 80 sophisticated equipment such as CNC, Director reading Spectrometer, CMM (Coordinate Measuring Machine), Rapid typing Machine and etc. Based on these facilities, Tobee® Pump has the abilities of material inspection, casting, welding, machining, assembling and the performance test of pump unit. The maximum weight of the casting by Tobee® Pump is about 12 tons, the maximum diameter of the casting can be machined by Tobee® pump is over 5 meters and the maximum flow rate of Tobee's Pump product is more than 80,000 cubic meters per hour. With an annual production of 1000~120,000 pumps, Presently,Tobee® Pump is the Top 10 pump manufacturer with high comprehensive capacity of design and producing.

Technical Capability

As a High & New Tech enterprise, Tobee® Pump owns a municipal research center with strong R&D research capability and a team of more than 150 engineers along with 45 senior engineers. There are material laboratory, physical lab, chemical lab, 3D scanning equipment, MAXUM, 3D coordinate measure machine, metallographic analysis software, casting simulation software, CFD computer aided design, PLM (product lifecycle management), CAPP and etc. hardware and software in Tobee® factory. In addition to these, Tobee® Pump continually introduce new technology technologies to improve the products comprehensive performance, like Lost Foam Casting and Vacuum Casting technology.

Market Standing

Tobee® pump's humongous market share and its unrelenting competitiveness in the pump market have made us rank Top 10 in China for many years and were also selected as the Pacesetter Enterprise in the Chinese Industrial Pump Industry. This warrants enough proof of our distinctive position in the pump market today.

R&D Capabilities

Since ours is a high tech enterprise of the Hebei Province, Tobee® Pump has a municipal level research centre and has strong abilities in product research and development because of our powerful research team. We also like to profess that we have a long standing technical cooperative relationship with many renowned research institutions which only shows the strength of Tobee's R&D capabilities.

Customer Evaluation

All the products manufactured by Tobee® Pump are well received by our customers and have gained high appraisal from the society noting certain qualities of our products like energy saving, overall efficiency, stable operation and long service life. Some of our customers refer to Tobee® Pumps simply as "Permanent Pumps" because of our quality and defect-free manufacturing ability.

Honors

1.Chinese Top 10 Slurry Pump Manufacturer

2.National Level II Measurement Unit

3.Advanced Enterprise of the Hebei Province

4.Trustful Enterprise on Contract Implementation of the Hebei Province

5.Manufacturing unit with the maximum Customer Satisfaction on both Quality and service in the Hebei Province

6.Production Quality Inspection-free Enterprise

7.Most Consumer Trusted Unit of the Hebei Province

8.Good Quality and Efficiency Enterprise of the Hebei Province

9.Top Super Credit Enterprise of Shijiazhuang City

10.Famous Brand Enterprise of Hebei Province

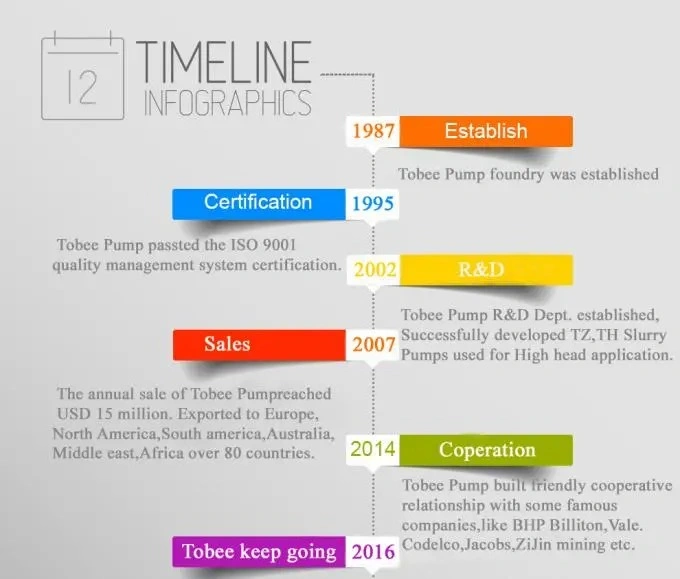

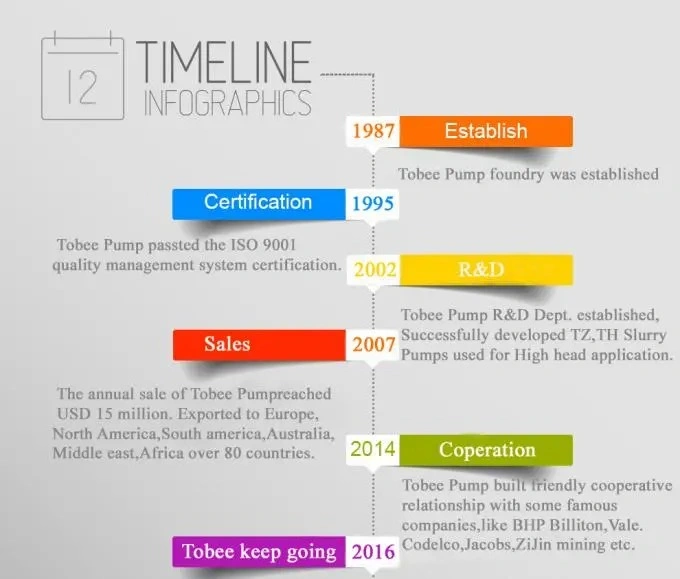

History

Our Team

In order to sustain and grow organizations we must recognize that your satisfaction is pivotal, as you ultimately determine the quality and the value that you perceive from our products. Tobee® Pump outlines a set of core corporate values that all members in the stakeholder value chain must uphold, and is aligned with the aim to exceed your satisfaction.

What we believe in - our core values

Customer focused

Anticipating and researching your wishes and requirements; responding to these and supplying added value.

Quality focused

Setting high standards for the qualtiy of our own and other people's work; constantly aiming for improvement.

Result driven

Focused on setting targets and actively achieving results.

Flexible

Able to adapt to changing circumstances and where necessary changing our approach or behaviour in order to still attain the intended goal.

Factory

Certification

FAQ

1.Q:Are you a factory or trading company?

A:We are a big manufacturing pump factory with 30 years experience.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:What is The material of your pumps?

A: The materials can be selected by High chrome alloy or Rubber,Polyurethane,Cast iron,SS304,SS316,CD4MCu,Duplex SS,Bronze etc. We can also choose material as customers' requirement.

4.Q:How can I get some samples?

A: We are honored to offer you samples.

5.Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has 15~20QC.

| Brand Name | Tobee | Size | 65mm |

| Capacity | 18-113m3/h | Head | 5-31.5m |

| Max.power | 15kw | Handing solids | 15mm |

| Submerged length | 900-2800mm | Materials | High chrome alloy, Rubber, Polyurethane, Ceramic, Stainless steel |

Tobee® Vertical Slurry Pumps

Tobee® industrial centrifugual electric vertical spindle pump is available in various standard lengths to suit common sump depths, for very deep sumps or where high shaft speeds limit the length of the pump, a suction extension pipe can be fitted to the bottom inlet to extend the depth of the pump by up to 2 meters. Pumping is maintained even when the top inlet is not submerged, thus enabling the level of liquid to be lowered right down to the bottom inlet or the bottom of any suction extension pipe. The wet parts of SPR vertical sump pump is interchangeable with the SP series hard metal lined heavy duty sump pumps.

Design Features:

√ Less wear, less corrosion

Wetted components are available in a wide range of alloys and elastomers, from which Weir Minerals selects the optimum combination of materials for maximum resistance to wear in virtually any industrial application, including those demanding both abrasion and corrosion resistance and where larger particles or high density slurries are encountered.

• Abrasion resistant A05 Ultrachrome® alloy.

• Abrasion/corrosion-resistant A49 Hyperchrome® alloy.

• Corrosion-resistant stainless steels.

• Natural and synthetic elastomers.

√ No submerged bearing failures

The robust cantilever shaft avoids the need for lower submerged bearings - which are often the source of premature bearing failure.

• Heavy duty roller bearings, above mountingplate.

• No submerged bearings.

• Labyrinth/flinger bearing protection.

• Rigid, large diameter shaft.

√ No shaft sealing problems

The vertical cantilever design requires no shaft seal.

√ No priming required

The top and bottom inlet design is ideally suited for "snore" conditions.

√ Less risk of blocking

The screened inlets and large impeller passages reduce the risk of blockages.

√ Zero ancillary water costs

The vertical cantilever design with no gland or submerged bearings avoids the need for expensive gland or bearing flushing water.

Tobee® SP/SPR Vertical Slurry Pumps Performance Parameters:

| Model | Matching power P (kw) | Capacity Q (m3/h) | Head H (m) | Speed n (r/min) | Eff.η (%) | Impeller dia. (mm) | Max.particles (mm) | Weight (kg) |

| 40PV-SP(R) | 1.1-15 | 7.2-29 | 4-28.5 | 1000-2200 | 40 | 188 | 12 | 300 |

| 65QV-SP(R) | 3-30 | 18-113 | 5-31.5 | 700-1500 | 60 | 280 | 15 | 500 |

| 100RV-SP(R) | 5.5-75 | 40-289 | 5-36 | 500-1200 | 62 | 370 | 32 | 920 |

| 150SV-SP(R) | 11-110 | 108-576 | 8.5-40 | 500-1000 | 52 | 450 | 45 | 1737 |

| 200SV-SP(R) | 15-110 | 180-890 | 6.5-37 | 400-850 | 64 | 520 | 65 | 2800 |

| 250TV-SP(R) | 18.5-200 | 261-1089 | 7-33.5 | 400-750 | 60 | 575 | 65 | 3700 |

| 300TV-SP(R) | 22--200 | 288-1267 | 6-33 | 350-700 | 50 | 610 | 65 | 3940 |

Tobee® SP/SPR Vertical Slurry Pumps Structural Drawing:

Tobee® SP/SPR Vertical Slurry Pumps Applications:

The SP/SPR verical slurry pumps are available in a wide range of popular sizes to suit most pumping applications. The SP/SPR sump pumps are proving their reliability and efficiency worldwide in: minerals processing, coal preparation, chemical processing, effluent handling, sand and gravel and almost every other tank, pit or hole-in-the ground slurry handling situation. The SP/SPR pump design with either hard metal (SP) or elastomer covered (SPR) components makes it ideal for abrasive and/or corrosive slurries, large particle sizes, high density slurries, continuous or "snore" operation, heavy duties demanding cantilever shafts

Company Information

Introduction

Hebei Tobee Group Co.,Limited, is a professional manufacturer in designing and manufacturing Slurry Pumps, Pipe & Fitting, Valve etc. Our factory is located in the High tech Development Zone, Shijiazhuang City, China. We specialized in Horizontal Slurry pump, Vertical slurry pump, Gravel sand pump, Dredging pump, Double suction pump, End suction pump, Multistage pump, Boiler feed water pump, Self priming pump, Inline centrifugal pump, Sea water pump, Chemical pump, Irrigation pump, Fire pump, API 610 centrifugal oil pump, Submersible slurry pump, Hydraulic slurry pump, Hydraulic dredge pump, Submersible sewage pump, Slurry Pump spares,Pipe & fittings and Valve in domestic and else in the world.

Capacity

Tobee® Pump has a wealth of experience in the manufacturing and service of pumps and accessories; in fact Tobee® Pump has machinery manufacturing experience of over 45 years having achieved great success with R&D and manufacturing of Pumps for more than 30 years. The annual production capacity of pumps in our factory surpasses 10,000 easily. Tobee® Pump has a tremendous market share that covers more than 30 cities in China including many provinces and autonomous regions and more than 80 countries.

Production Capability

Tobee® Pump has over 80 sophisticated equipment such as CNC, Director reading Spectrometer, CMM (Coordinate Measuring Machine), Rapid typing Machine and etc. Based on these facilities, Tobee® Pump has the abilities of material inspection, casting, welding, machining, assembling and the performance test of pump unit. The maximum weight of the casting by Tobee® Pump is about 12 tons, the maximum diameter of the casting can be machined by Tobee® pump is over 5 meters and the maximum flow rate of Tobee's Pump product is more than 80,000 cubic meters per hour. With an annual production of 1000~120,000 pumps, Presently,Tobee® Pump is the Top 10 pump manufacturer with high comprehensive capacity of design and producing.

Technical Capability

As a High & New Tech enterprise, Tobee® Pump owns a municipal research center with strong R&D research capability and a team of more than 150 engineers along with 45 senior engineers. There are material laboratory, physical lab, chemical lab, 3D scanning equipment, MAXUM, 3D coordinate measure machine, metallographic analysis software, casting simulation software, CFD computer aided design, PLM (product lifecycle management), CAPP and etc. hardware and software in Tobee® factory. In addition to these, Tobee® Pump continually introduce new technology technologies to improve the products comprehensive performance, like Lost Foam Casting and Vacuum Casting technology.

Market Standing

Tobee® pump's humongous market share and its unrelenting competitiveness in the pump market have made us rank Top 10 in China for many years and were also selected as the Pacesetter Enterprise in the Chinese Industrial Pump Industry. This warrants enough proof of our distinctive position in the pump market today.

R&D Capabilities

Since ours is a high tech enterprise of the Hebei Province, Tobee® Pump has a municipal level research centre and has strong abilities in product research and development because of our powerful research team. We also like to profess that we have a long standing technical cooperative relationship with many renowned research institutions which only shows the strength of Tobee's R&D capabilities.

Customer Evaluation

All the products manufactured by Tobee® Pump are well received by our customers and have gained high appraisal from the society noting certain qualities of our products like energy saving, overall efficiency, stable operation and long service life. Some of our customers refer to Tobee® Pumps simply as "Permanent Pumps" because of our quality and defect-free manufacturing ability.

Honors

1.Chinese Top 10 Slurry Pump Manufacturer

2.National Level II Measurement Unit

3.Advanced Enterprise of the Hebei Province

4.Trustful Enterprise on Contract Implementation of the Hebei Province

5.Manufacturing unit with the maximum Customer Satisfaction on both Quality and service in the Hebei Province

6.Production Quality Inspection-free Enterprise

7.Most Consumer Trusted Unit of the Hebei Province

8.Good Quality and Efficiency Enterprise of the Hebei Province

9.Top Super Credit Enterprise of Shijiazhuang City

10.Famous Brand Enterprise of Hebei Province

History

Our Team

In order to sustain and grow organizations we must recognize that your satisfaction is pivotal, as you ultimately determine the quality and the value that you perceive from our products. Tobee® Pump outlines a set of core corporate values that all members in the stakeholder value chain must uphold, and is aligned with the aim to exceed your satisfaction.

What we believe in - our core values

Customer focused

Anticipating and researching your wishes and requirements; responding to these and supplying added value.

Quality focused

Setting high standards for the qualtiy of our own and other people's work; constantly aiming for improvement.

Result driven

Focused on setting targets and actively achieving results.

Flexible

Able to adapt to changing circumstances and where necessary changing our approach or behaviour in order to still attain the intended goal.

Factory

Certification

FAQ

1.Q:Are you a factory or trading company?

A:We are a big manufacturing pump factory with 30 years experience.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:What is The material of your pumps?

A: The materials can be selected by High chrome alloy or Rubber,Polyurethane,Cast iron,SS304,SS316,CD4MCu,Duplex SS,Bronze etc. We can also choose material as customers' requirement.

4.Q:How can I get some samples?

A: We are honored to offer you samples.

5.Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has 15~20QC.